A special device for replacing hot shear blades and hydraulic cylinders of a bar unit

A special device and hydraulic cylinder technology, which is applied in the field of special devices for replacing hot shear blades and hydraulic cylinders of bar units, can solve the problems of high risk, low efficiency of blades and hydraulic cylinders, etc., improve efficiency, reduce construction costs, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

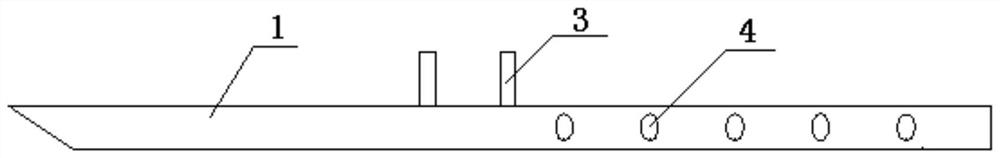

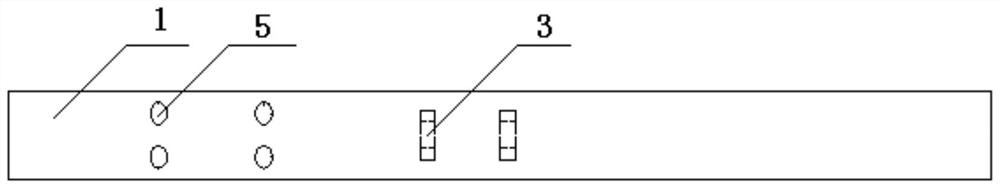

[0026] Specific embodiment one, such as Figure 1 to Figure 3 Shown:

[0027] A special device for replacing hot shear blades of a bar unit, comprising a blade replacement device body 1, the blade replacement device body 1 is a channel steel structure, wherein the groove wall at one end of the channel steel has a slope, and the groove at the other end There are symmetrical positioning holes 4 on the wall; the outer side of the bottom of the groove is fixedly provided with a lifting piece.

[0028] The hoisting parts are hoisting nuts 3 .

[0029] There are 2 lifting nuts 3.

[0030] There are multiple positioning holes 4, and in this embodiment, five positioning holes are arranged on each groove wall.

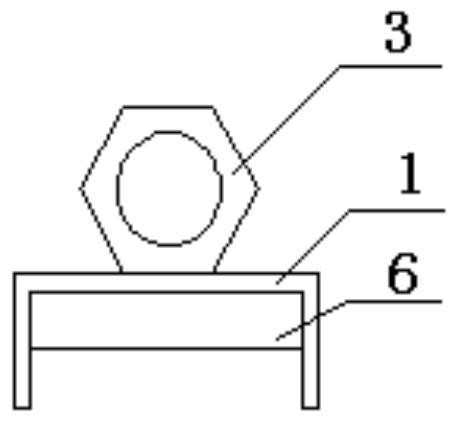

[0031] A reinforcing rib 6 is arranged inside the groove, and a 10mm thick steel plate is selected for the reinforcing rib to be welded inside the groove.

[0032] This embodiment adopts 16# channel steel as the blade changing device body.

specific Embodiment 2

[0033] Specific embodiment two, such as Figure 1 to Figure 4 Shown:

[0034] A special device for hydraulic cylinder replacement, comprising a blade replacement device body and a hydraulic cylinder replacement device body 2, wherein the bottom of the blade replacement device body has a first fixing hole 5 near the end of the slope; the hydraulic cylinder replacement device body There is an arc-shaped slot at one end, and a second fixing hole 7 matching the first fixing hole 5 at the other end. The end of the arc-shaped slot has a locking structure for clamping the top of the hydraulic cylinder.

[0035] The locking structure in this embodiment is a bolt locking hole 8 .

[0036] The first fixing hole and the second fixing hole are fixed by bolts; the blade changing device body is movably connected to the fixing member, and can rotate 360 degrees on a vertical plane.

[0037] The specific operation steps for replacing the blade through this device are as follows:

[0038]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com