Method for operating an inkjet printing machine

An inkjet printer, ink technology, applied in printing, copying/marking methods, printing devices, etc., can solve problems such as inapplicable elimination of precipitation or agglomeration, and achieve the effect of avoiding increased and reliable costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

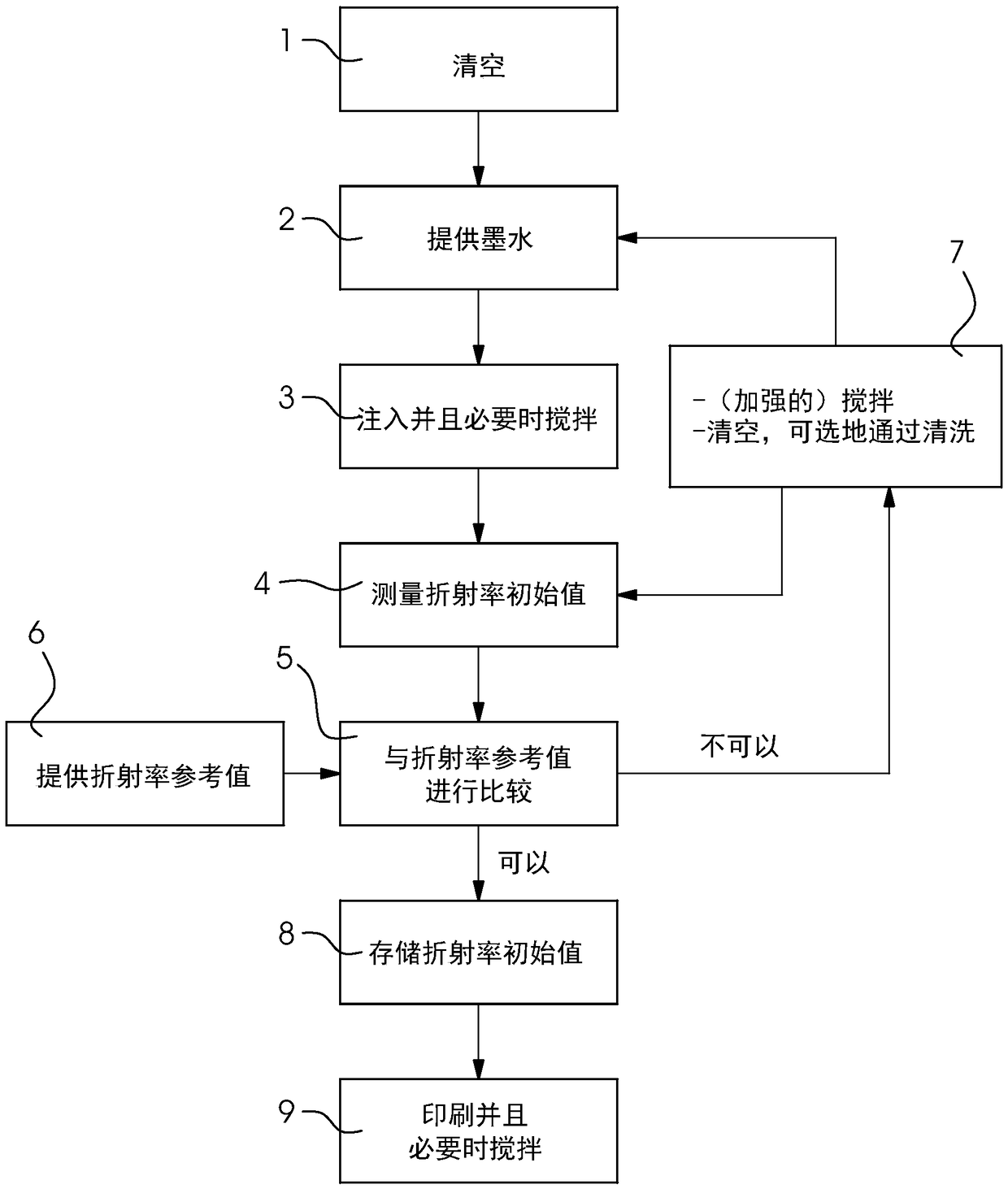

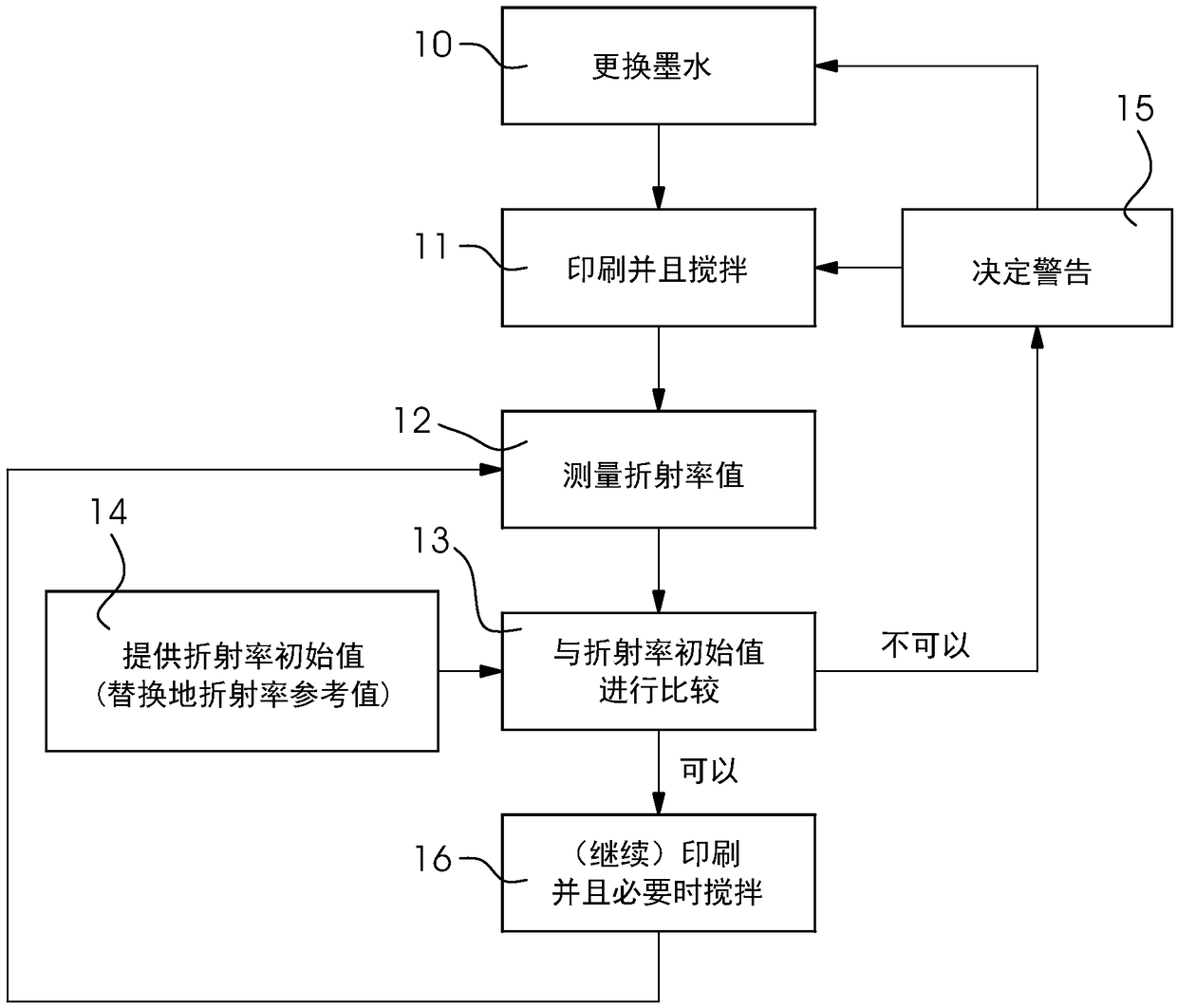

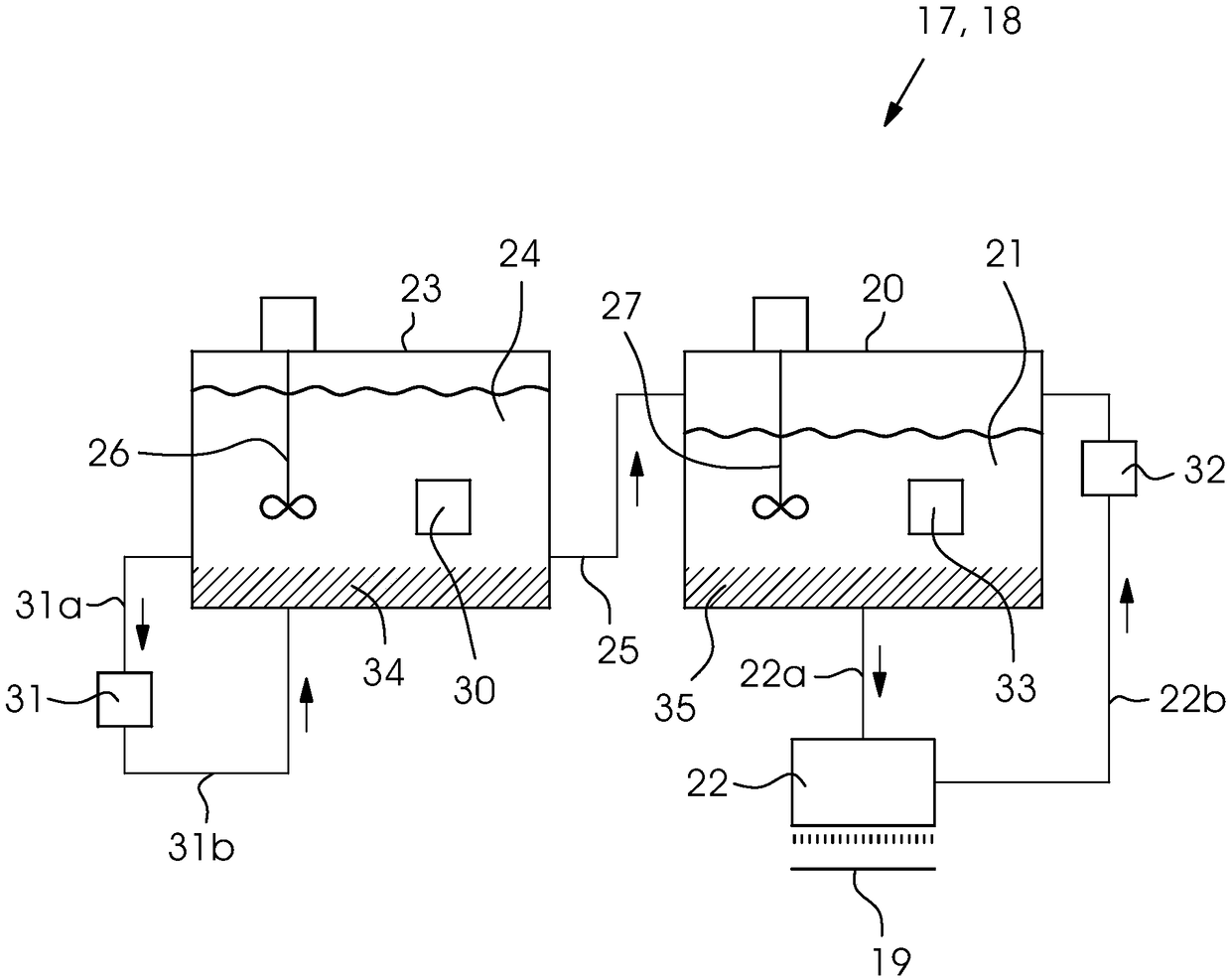

[0045] figure 1 A flow chart showing a series of method steps of a preferred embodiment of the method according to the invention. The method steps are described below (refer also to the reference numerals image 3 ):

[0046] Step 1 (optional): the ink supply 17 of the inkjet printer 18 or the ink cartridge 20 and / or the ink storage container of said inkjet printer and optionally the ink lines 22a, 22b of said inkjet printer, 25 and 31a are emptied of liquid ink 21 , 24 .

[0047] Step 2: Providing liquid ink 24, ie injecting ink into the storage container 23 (or providing an already filled storage container).

[0048] Step 3: The ink 24 is brought, filled, preferably pumped from the storage container 23 into the ink cartridge 20 and present there as ink 21 . Optionally, the ink 21 is guided using an agitator 27 . Ink is brought, preferably pumped, to at least one inkjet printhead 22 via ink line 22a and brought, preferably pumped, back to ink cartridge 20 via ink line 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com