Mounting bracket for prefabricated component, prefabricated wall comprising same, and mounting method of prefabricated wall

A technology of prefabricated components and mounting brackets, which is applied in building construction, building material processing, construction, etc., can solve the problems of inability to adjust prefabricated floor slabs, cumbersome and other problems, and achieve the effect of good verticality and convenient connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

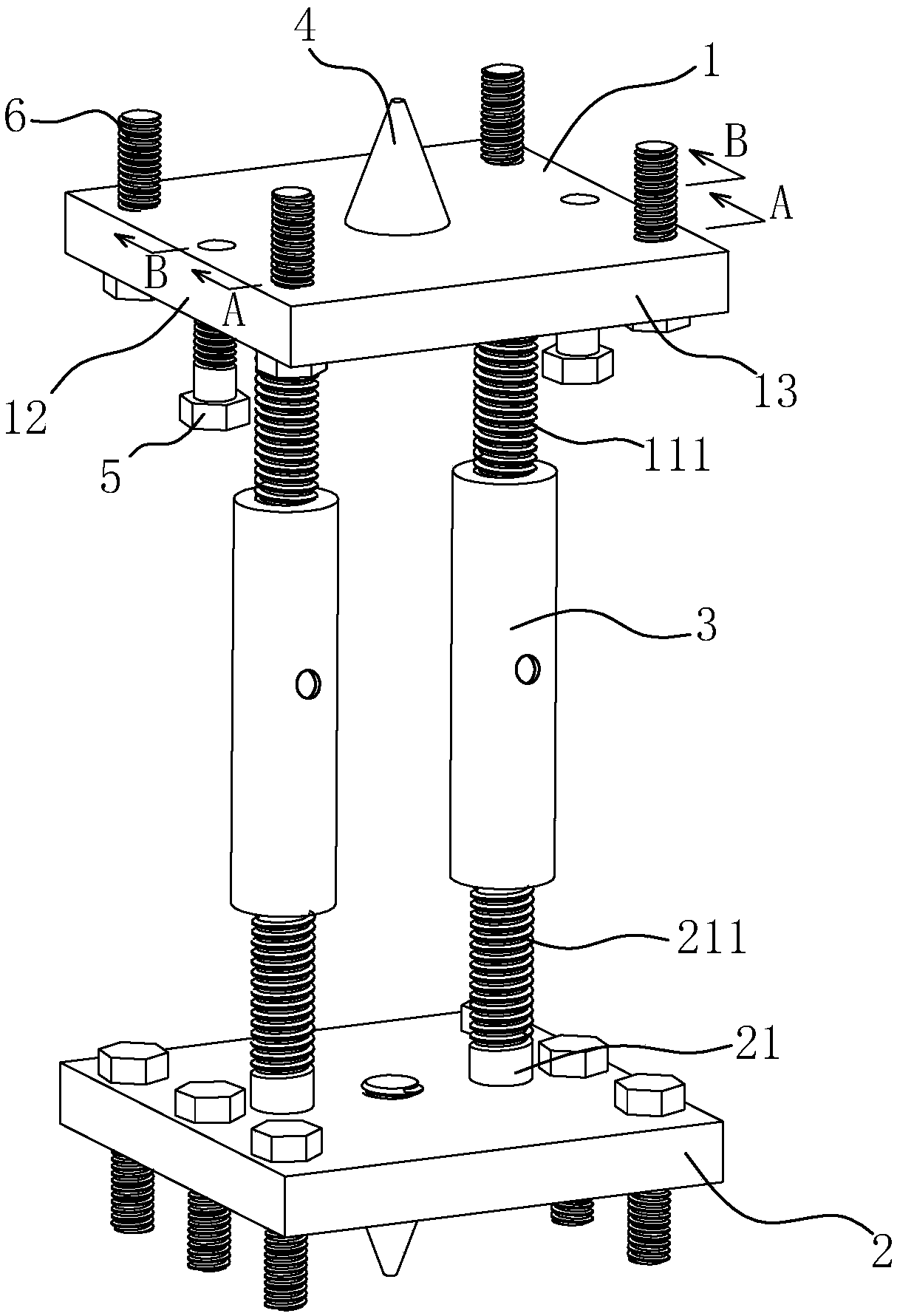

[0041] Embodiment 1: A mounting bracket for prefabricated components, such as figure 2 As shown, it is used in prefabricated buildings to support prefabricated components such as prefabricated wall panels and prefabricated columns to facilitate the construction of superstructures.

[0042] The mounting bracket of the prefabricated component includes an upper support plate 1, a lower support plate 2 opposite to the upper support plate 1, and two upper adjustment columns 11 are symmetrically fixed on the lower end of the upper support plate 1 (combined with image 3 ), the upper end of the lower support plate 2 is fixed with two lower adjustment columns 21 opposite to the upper adjustment column 11 . The upper adjustment column 11 is provided with positive threads 111 , and the lower adjustment column 21 is provided with reverse threads 211 , and the outer circumferences of the upper adjustment column 11 and the lower adjustment column 21 are threadedly connected to the sleeve ...

Embodiment 2

[0048] Embodiment two: a kind of prefabricated wall body, such as Figure 4 As shown, it includes the first prefabricated wall panel 7 supported on the ground, and the two sides of the upper end surface of the first prefabricated wall panel 7 respectively use brackets to support the prefabricated floor slab 9. There is an installation gap 90, and the lower formwork 91 is supported at the gap to facilitate pouring concrete later. The mounting bracket of the prefabricated component in the first embodiment is fixed on the upper end of the first prefabricated wall panel 7, and the second prefabricated wall panel 8 is connected above the mounting bracket of the prefabricated component, and the second prefabricated wall panel 8 is hoisted to a suitable position, so as to It is convenient to adjust the levelness of the second prefabricated wall panel 8 . Among them, a plurality of connecting steel bars 73 are respectively extended around the first prefabricated wall panel 7 and the ...

Embodiment 3

[0051] Embodiment three: a method for installing a prefabricated wall, comprising the following steps:

[0052] S1. Support the first prefabricated wall panel 7 on the ground, respectively hoist the prefabricated floor slab 9 perpendicular to the first prefabricated wall panel 7 on both sides of the upper end surface of the first prefabricated wall panel 7, and the lower end surface of the prefabricated floor slab 9 is supported by a bracket to facilitate formation relatively stable infrastructure;

[0053] S2. When the prefabricated floor slab 9 is hoisted, there is an installation gap 90 between the prefabricated floor slab 9 and the first prefabricated wall panel 7; since the installation gap 90 is relatively close to the lower support plate 2 of the installation bracket of the prefabricated component, it can pass through the installation gap 90 adjusts the positioning column 4 and the fixing bolt 6 on the lower support plate 2. After the adjustment is completed, the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com