Pneumatic rotary executing mechanism

A pneumatic actuator and actuator technology, applied in the field of machinery, can solve problems such as safety accidents and production impacts, and achieve the effects of high precision, simple installation and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

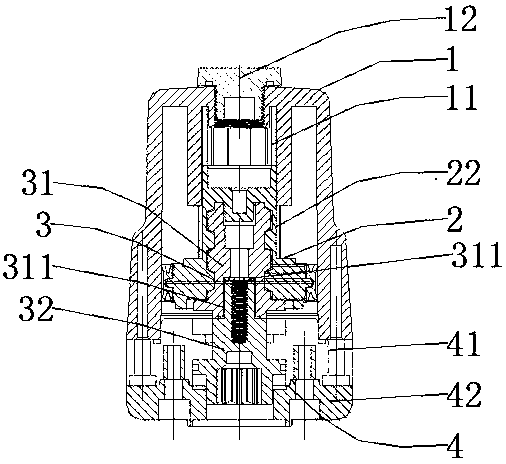

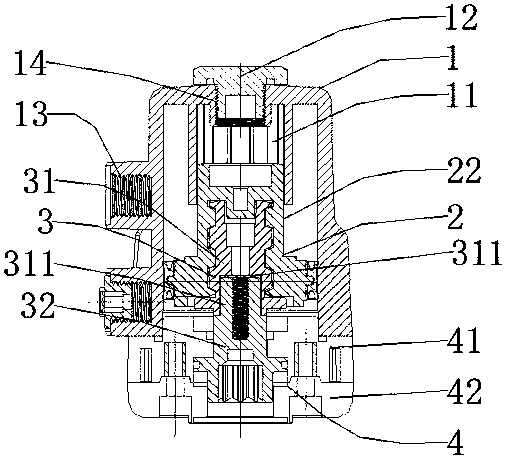

[0028] Example 1: A pneumatic rotary actuator

[0029] see Figures 1 to 6 , a pneumatic rotary actuator, which includes: an upper housing 1, a pneumatic actuator 2, a screw actuator 3, and a lower housing 4;

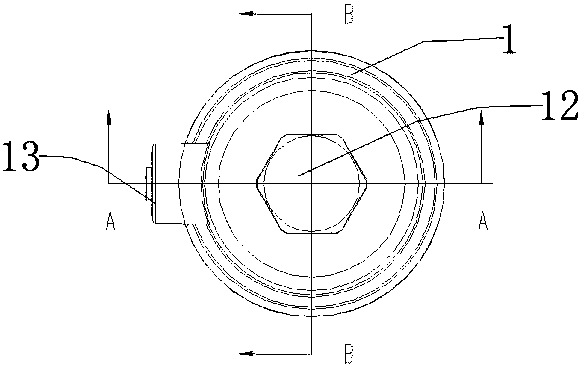

[0030] The upper casing 1 has a barrel-shaped structure, and the upper bottom is provided with a through hole 14;

[0031] The inside of the upper housing 1 is provided with a guide sleeve 11, and the inside of the guide sleeve 11 is provided with internal splines;

[0032] The guide sleeve 11 is arranged coaxially with the through hole 14;

[0033] The through hole 14 is provided with a bolt plug 12;

[0034] One side of the upper casing 1 is provided with a pneumatic control interface 13;

[0035] The pneumatic actuator 2 is piston-shaped and matches the inside of the upper casing 1;

[0036] The outer side of the pneumatic actuator 2 is provided with an external spline 22, and the external spline 22 is matched with the internal spline inside the guide sleeve 11;...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap