Stubble cleaning subsoiling fertilizer applying plowing combined operation machine

A combined operation machine and stubble removal technology, which is applied to agricultural machinery and tools, agriculture, harvesters, etc., can solve the problems of single function of machines and tools, and achieve the effects of high production efficiency, reduced damage, and good matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

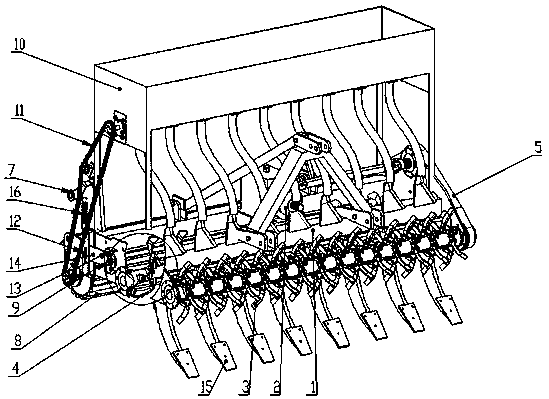

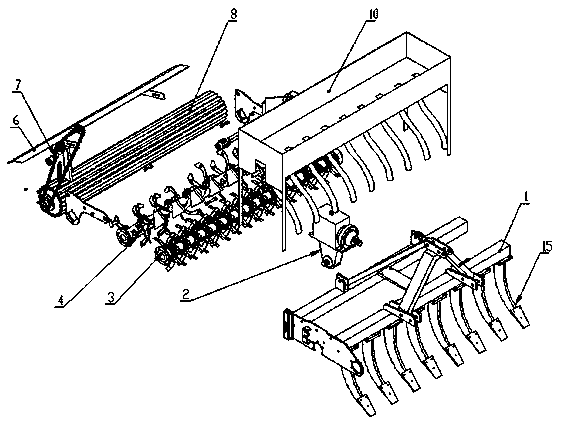

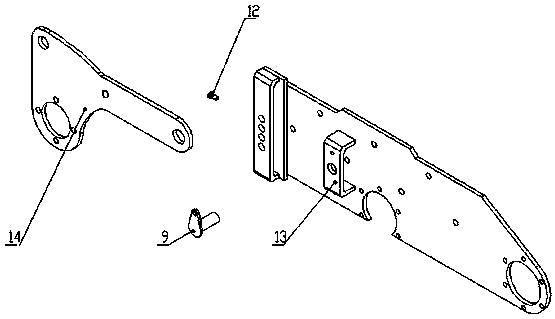

[0016] Such as figure 1 , figure 2 , image 3 As shown, a combination operation machine for stubble removal, subsoiling, fertilization, plowing and tillage includes a frame 1, a central reversing reduction gear box 2, a stubble removal device 3, a rotary tillage device 4, a side transmission gear box 5, a tensioning device 7, and a suppression limiter. Deep roller 8, crank arm pin shaft 9, fertilization mechanism 10, chain 11, regulating arm 14, deep pine tooth 15. A stubble removal device 3 is installed at the front and bottom of the frame 1, a rotary tiller 4 is installed on the rear frame 1 of the stubble removal device 3, a central reversing reduction box 2 is installed in the middle of the frame 1, and a stubble removal device 3 is arranged at the front and bottom of the frame 1. 3 is to crush the straw, root stubble and weeds on the surface to prepare for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com