Heating pot with residue discharge function

A heating pot and functional technology, which is applied in the cleaning device of the baking cavity, food oven, baking, etc., can solve the problem that the heating pot cannot discharge slag, etc., and achieve the effect of ingenious structure, novel concept, and quick and convenient cleaning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

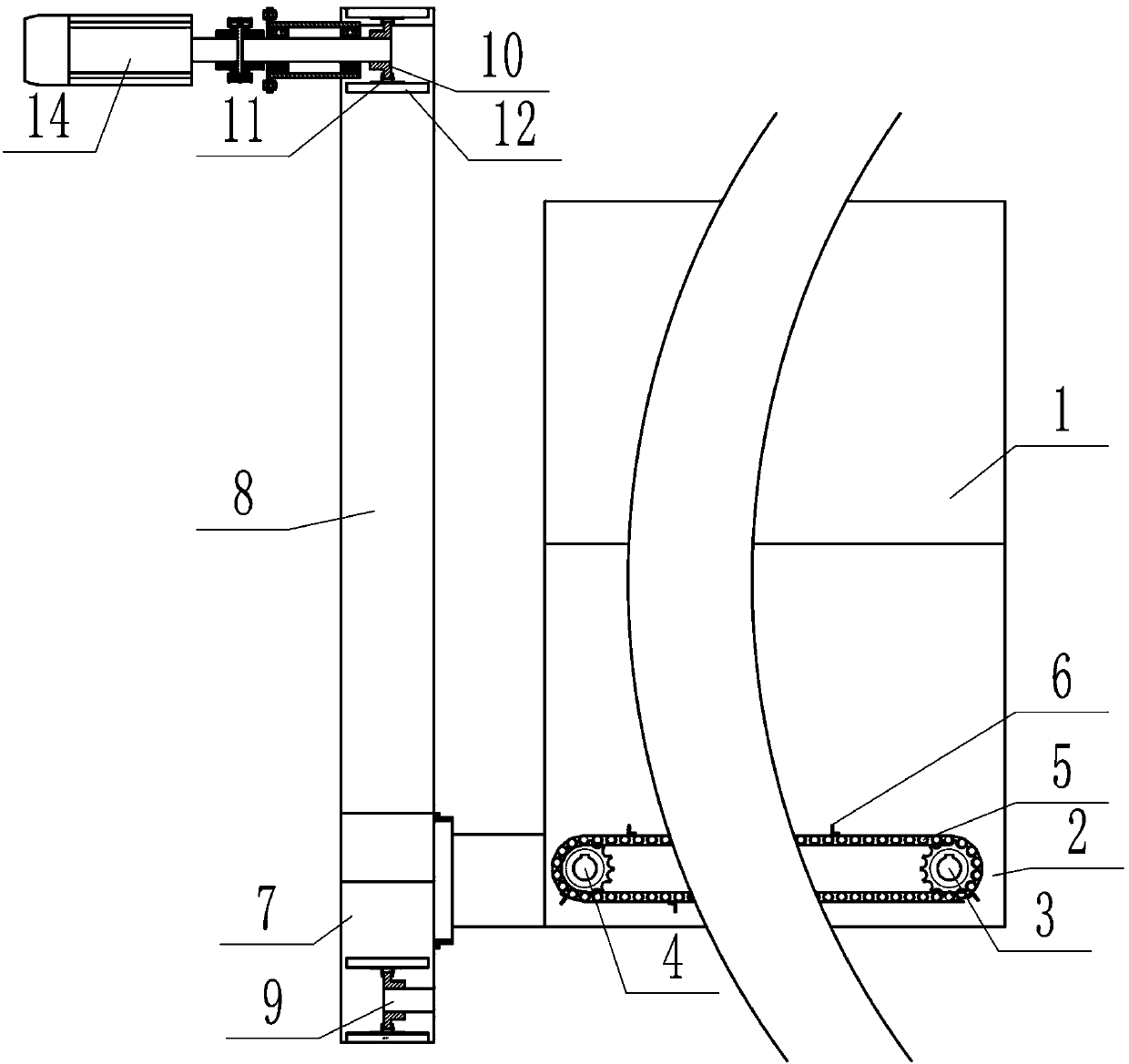

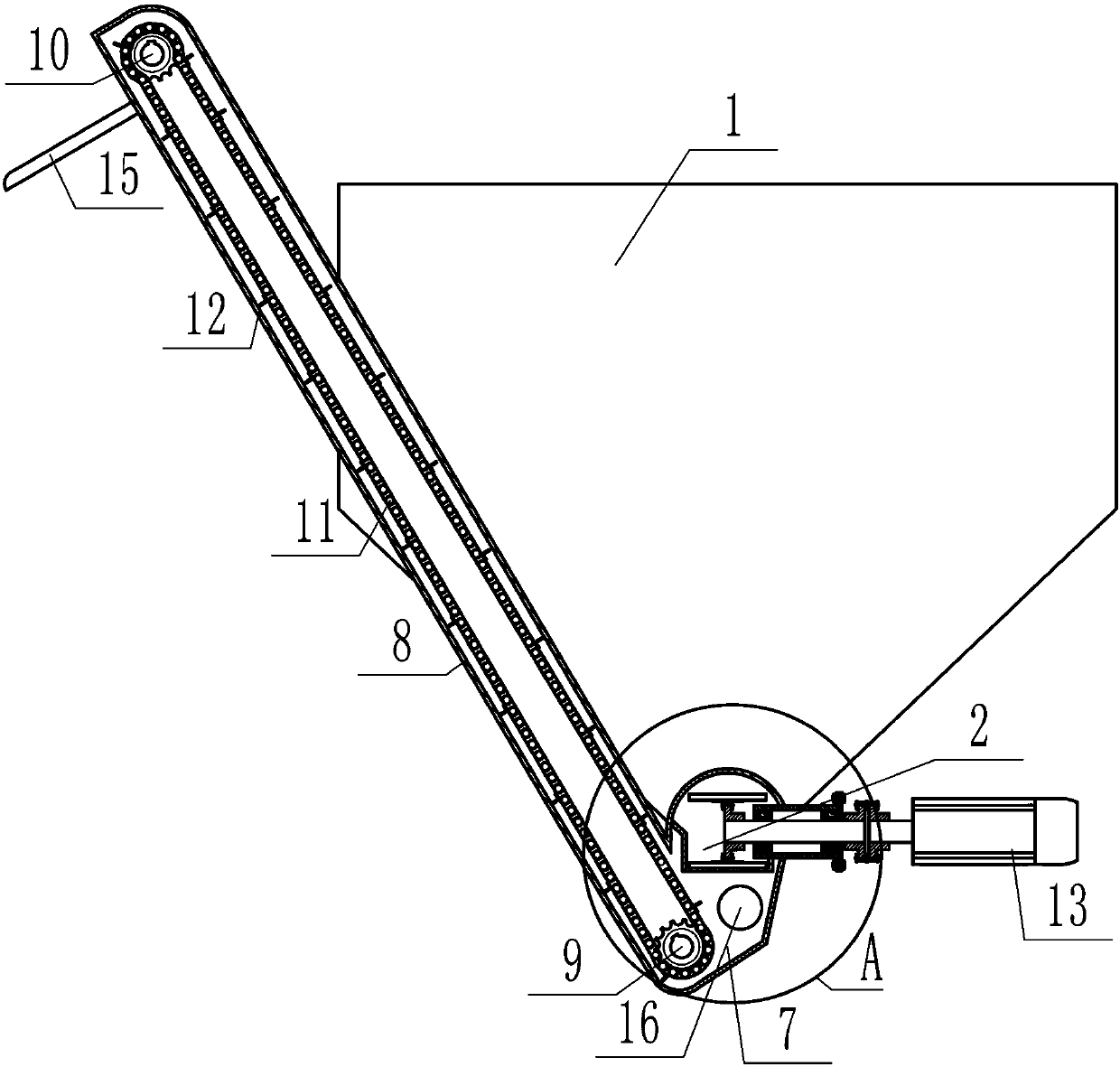

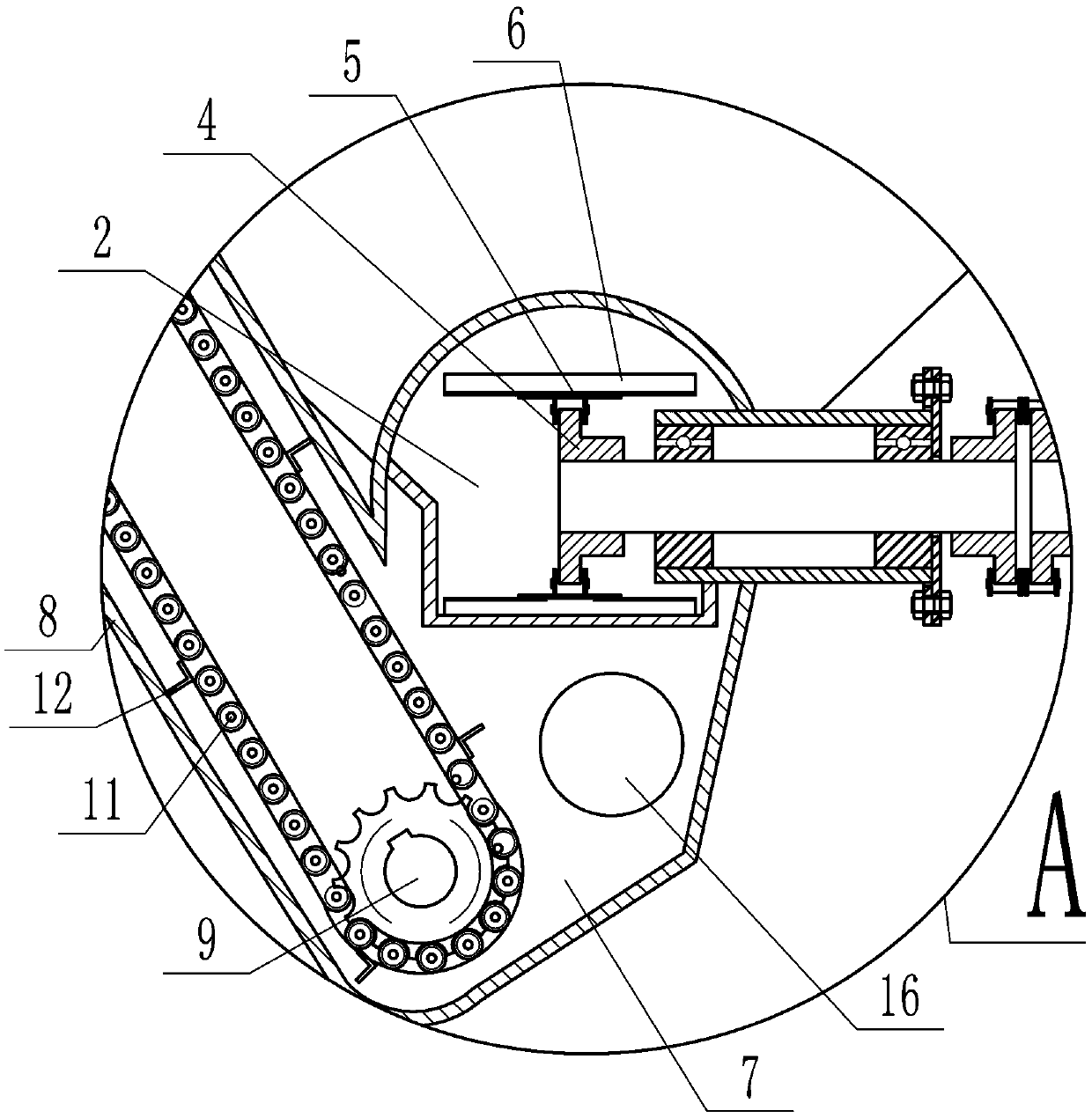

[0014] Depend on Figure 1 to Figure 3 As can be seen, the present invention comprises a heating pot 1, a heating tube is arranged in the heating pot 1, a settling tank 2 arranged along its length direction is provided at the bottom of the heating pot 1, one end of the settling tank 2 is placed in the heating pot 1, and the other end It penetrates and protrudes from the left end surface of the heating pot 1. One end of the settling tank 2 placed in the heating pot 1 is provided with a first sprocket 3, and the other end is provided with a second sprocket 4. The first sprocket 3 and the second sprocket 4. Connected by the first chain 5, the outer edge of the first chain 5 is fixed with the first scraper 6 that can contact the inner side wall of the settling tank 2 and can slide, and the second sprocket 4 rotates to drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com