Carriage door and manufacturing method thereof

A manufacturing method and carriage door technology, which is applied in the field of carriage doors and its manufacture, can solve the problems of poor commodity appearance and high production cost of carriage doors, and achieve the effects of improving appearance commodity, low production cost, and fast welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

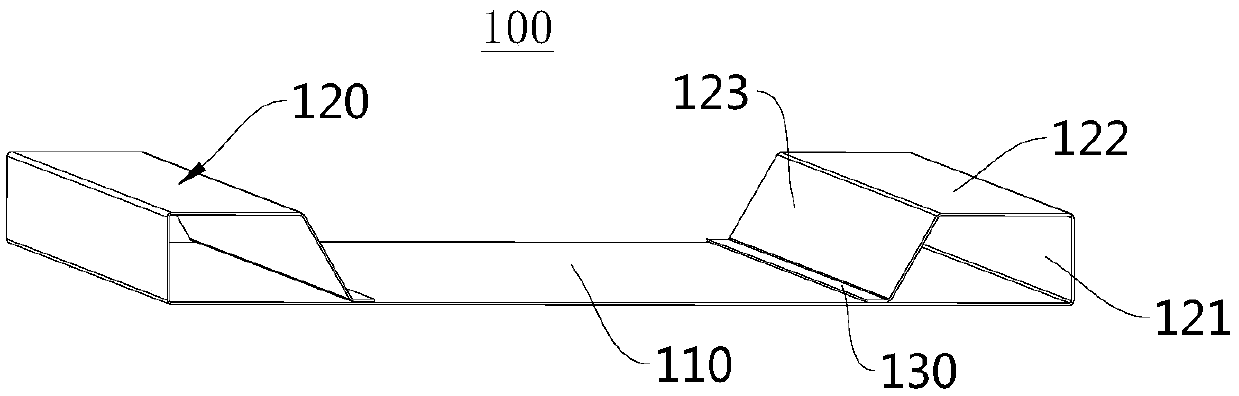

[0038] figure 1 A schematic diagram of the appearance and structure of the compartment door 100 in the manufacturing method of the compartment door 100 provided in this embodiment. Please refer to figure 1 , the present embodiment provides a method for manufacturing the compartment door 100 , which uses rolling to make the sheet material into a door panel base material with a predetermined shape. The door panel base material includes a door panel body 110 and two reinforcing parts 120 fixedly connected to opposite ends of the door panel body 110. The free ends of the reinforcement parts 120 have flanges 130, and the flanges 130 are welded and fixed on the door panel body 110 by spot welding. .

[0039] The manufacturing method of the compartment door 100 provided in this embodiment is further described below:

[0040] The welding method provided in this embodiment comprises the following steps:

[0041] SO1: Roll the board to obtain the base material of the door panel; the...

Embodiment 2

[0053] This embodiment also provides a method for manufacturing the compartment door 100. The method for manufacturing the compartment door 100 provided by this embodiment will be specifically described below. The method includes the following steps.

[0054] SO1: Roll the board to obtain the base material of the door panel; the base material of the door panel includes a door panel body 110 and two reinforcing parts 120 integrally formed at opposite ends of the door panel body 110; the free ends of the two reinforcing parts 120 are provided with flanging 130.

[0055] The board is put into the rolling device, and the board is rolled into a door panel base material with a preset shape by the joint action of multiple sets of rollers. The door panel base material includes a door panel body 110 and two reinforcing parts 120 integrally formed at opposite ends of the door panel body 110 , and a flange 130 is provided at a free end of the reinforcing part 120 . Specifically, the rei...

Embodiment 3

[0066] This embodiment also provides a method for manufacturing the compartment door 100. The method for manufacturing the compartment door 100 provided by this embodiment will be specifically described below. The method includes the following steps.

[0067] SO1: Roll the board to obtain the base material of the door panel; the base material of the door panel includes a door panel body 110 and two reinforcing parts 120 integrally formed at opposite ends of the door panel body 110; the free ends of the two reinforcing parts 120 are provided with flanging 130.

[0068] The board is put into the rolling device, and the board is rolled into a door panel base material with a preset shape by the joint action of multiple sets of rollers. The door panel base material includes a door panel body 110 and two reinforcing parts 120 integrally formed at opposite ends of the door panel body 110 , and a flange 130 is provided at a free end of the reinforcing part 120 . Specifically, the rei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com