Anti-thermal-deformation drilling equipment for cleaning gun head metal connecting piece

A technology for metal connectors and drilling equipment, which is applied in the direction of metal processing equipment, drilling/drilling equipment, metal processing machinery parts, etc., can solve the problems of affecting drilling accuracy and thermal deformation, so as to prevent thermal deformation and improve The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, the technical solutions of the present invention will be described in detail through specific examples.

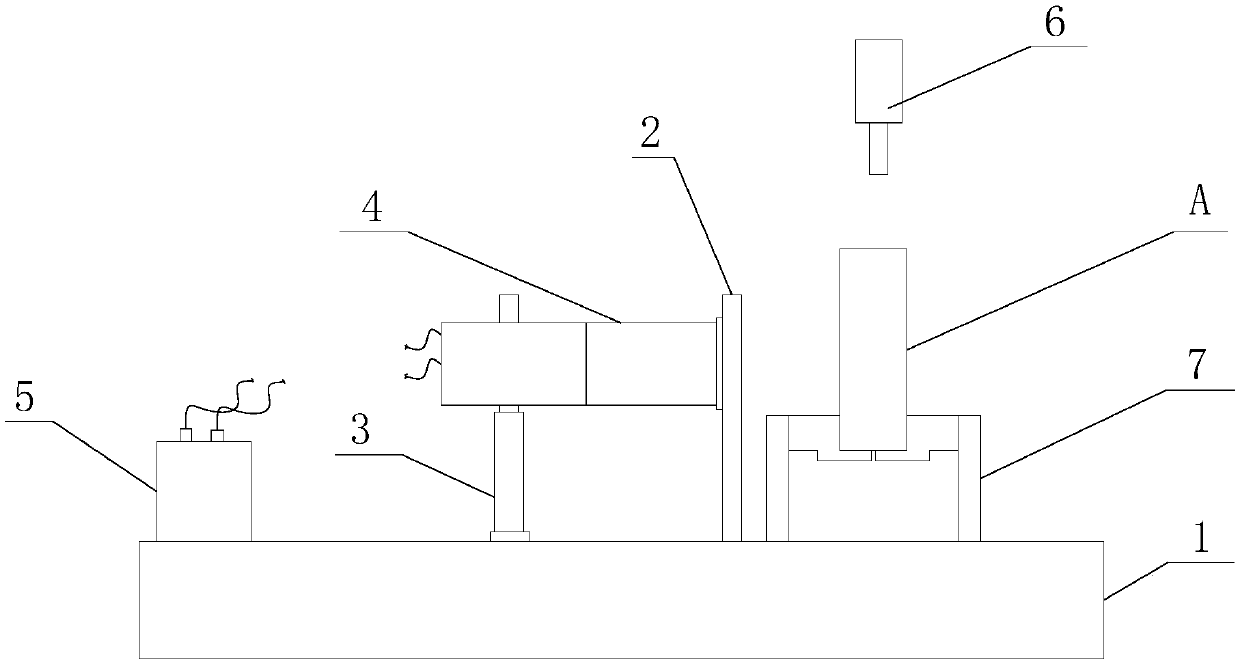

[0019] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a thermal deformation-resistant cleaning gun head metal connector drilling equipment proposed by the present invention.

[0020] refer to figure 1 According to the embodiment of the present invention, a drilling equipment for cleaning the metal connector of the gun head against thermal deformation is proposed, including: a support platform 1, a first pole 2, a second pole 3, a cooling belt 4, a refrigerant supply mechanism 5, The drilling mechanism 6, the first driving mechanism, the second driving mechanism and the third driving mechanism, wherein: the support platform 1 is provided with a clamping mechanism 7 for lifting the workpiece and keeping the workpiece fixed.

[0021] The first vertical rod 2 and the second vertical rod 3 are vertically installed on the support pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com