Bidirectional noncontact type cooling dynamic sealing method for two-grade liquid ring pump

A non-contact, liquid ring pump technology, used in liquid fuel engines, components of pumping devices for elastic fluids, pumps, etc. Impeller hub thermal deformation, affecting the stability of liquid ring pump operation, etc., to prevent gas backflow, solve wear, and prevent thermal deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] The present invention is an improvement on the basis of the prior art, and the newly added parts are all realized by using conventional machining techniques for common machining materials.

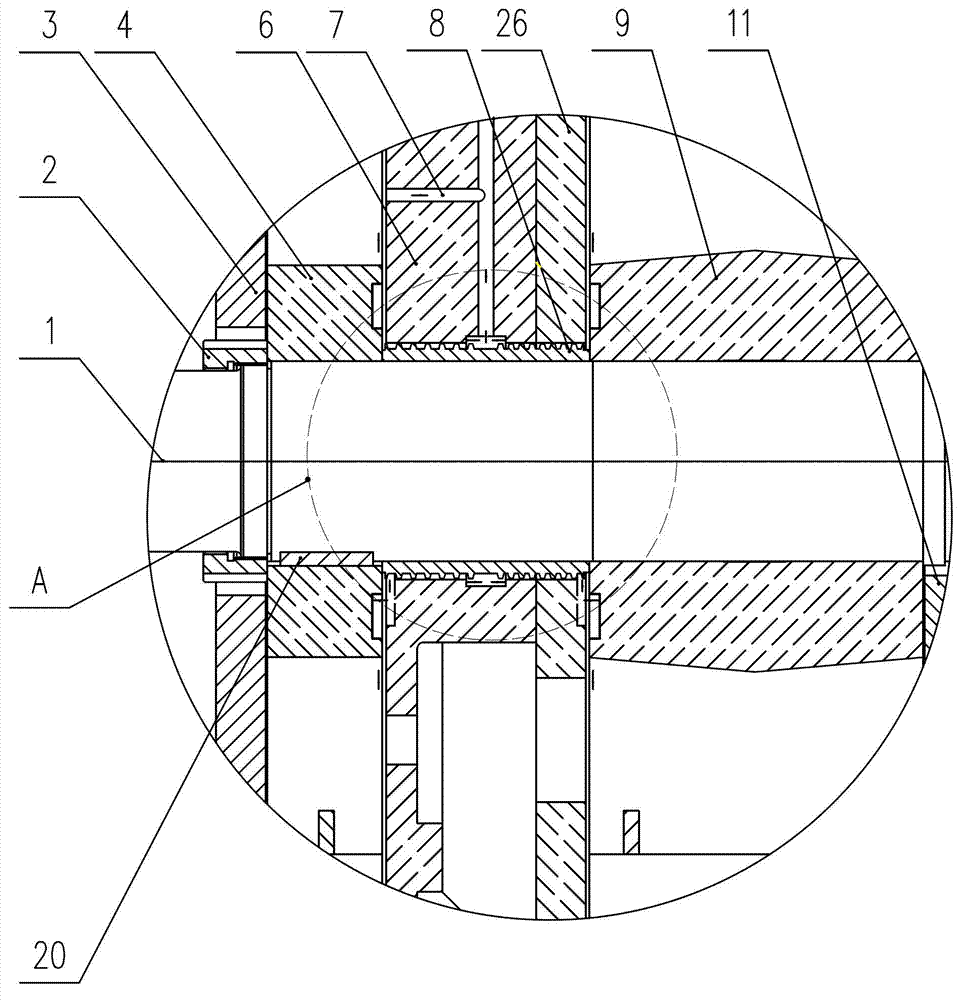

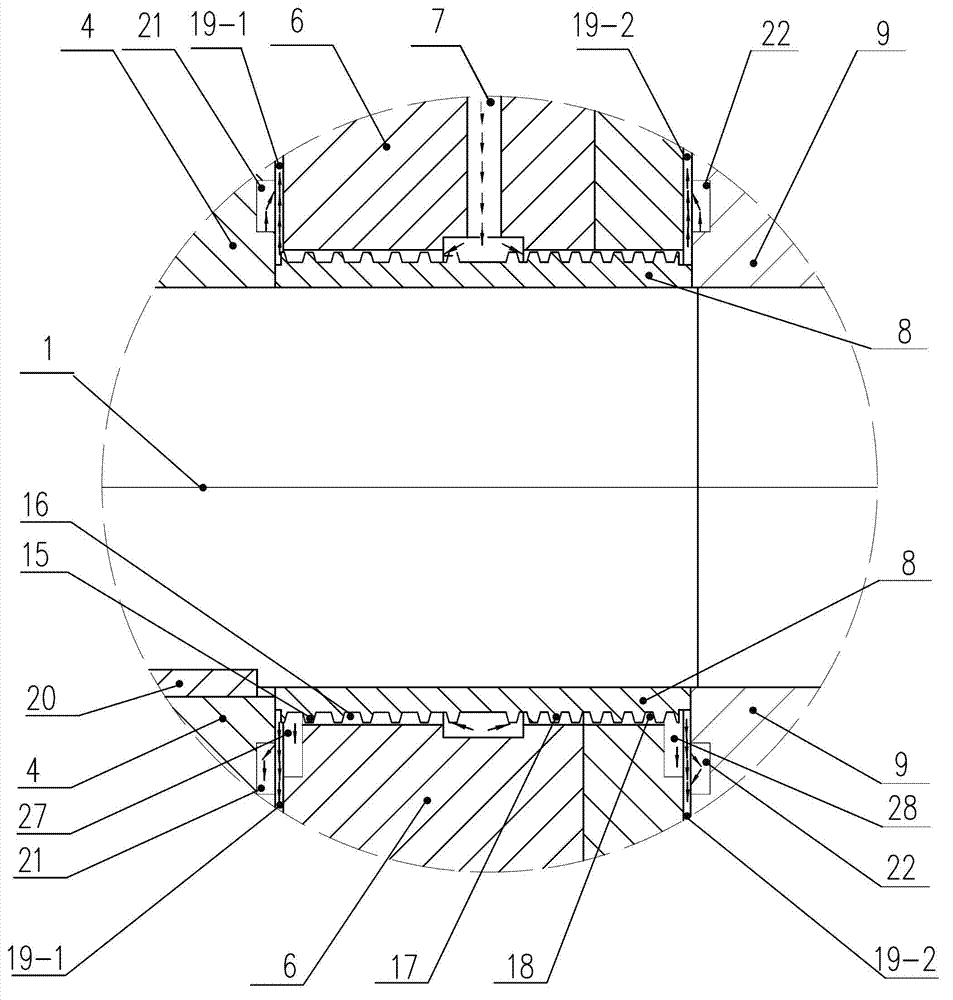

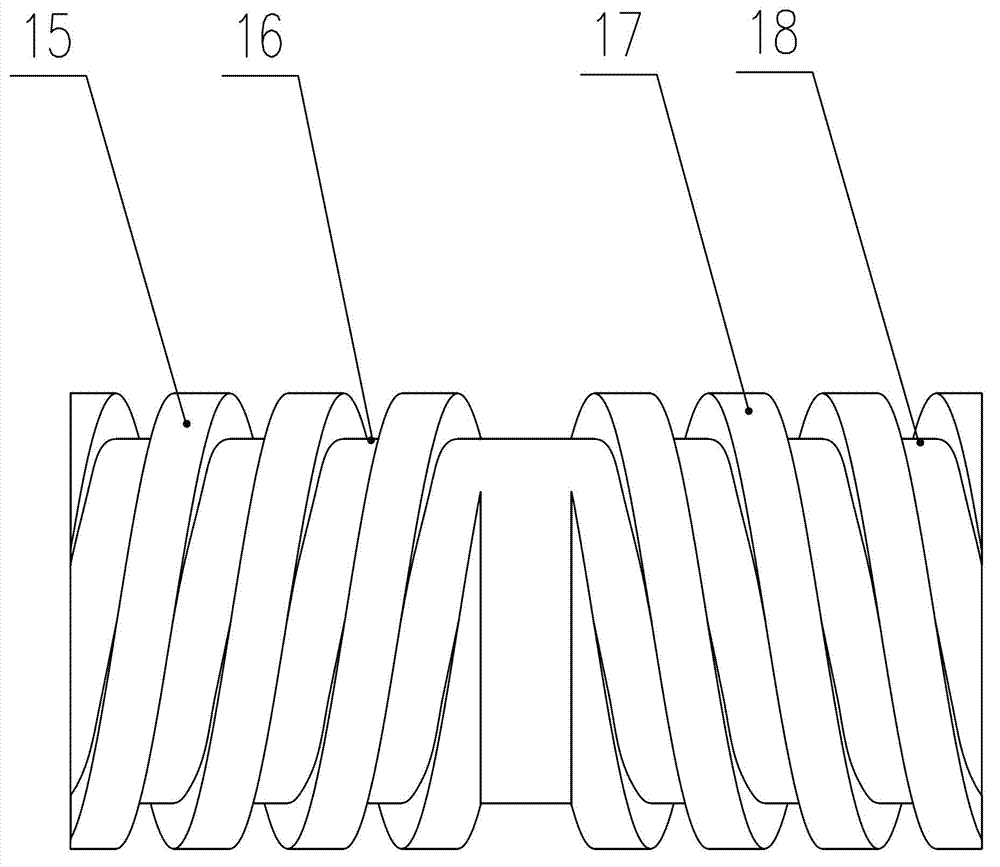

[0047] Its outstanding invention point is to break through the stylized thinking of the existing technology and find another way; a two-way spiral liquid supply mechanism is set between the rotating component and the stationary component of the two-stage liquid ring pump-the combination of the middle wall component, and the non-contact dynamic seal is adopted. ; The sealing structure between the intermediate wall assembly 6 and the liquid ring pump shaft 1 is simplified, a hydraulic seal is realized, and gas backflow between the high and low pressure chambers is effectively prevented. In addition, the cooling of the hub of the impeller of the high and low pressure chamber is realized during the circulation of the sealing liquid, which effectively prevents the thermal deformation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com