Liquid cooling narrow-face copper plate for metal continuous casting crystallizer

A continuous casting crystallizer and narrow-faced copper plate technology, which is applied in the field of metal solidification and continuous casting, can solve the problems of unspecified side chamfer cooling mode, unfavorable product cooling consistency, and cooling surface affecting cooling effect, etc., to achieve Solve the cracking of corners, avoid thermal deformation, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

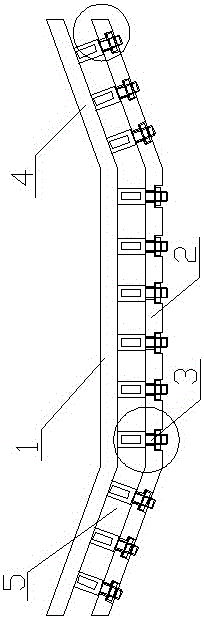

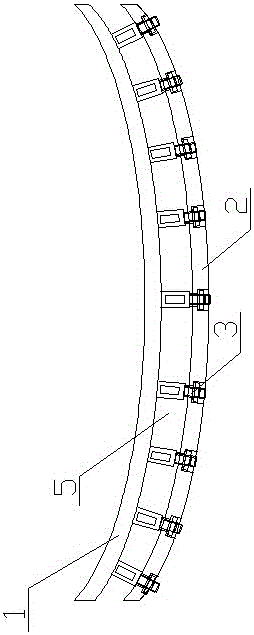

[0039] A metal continuous casting crystallizer liquid-cooled narrow-sided copper plate, comprising a working copper plate 1 whose back is connected to a back plate 2 through a connecting piece 3, the side of the working copper plate 1 is bent to the upper part of the working surface of the working copper plate to form a chamfered surface 4. A coolant gap 5 is formed between the connector 3 and the back plate 2 through the protrusions provided thereon.

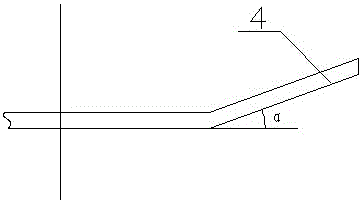

[0040] The angle α between the chamfering surface 4 and the horizontal plane of the working copper plate is 20°.

[0041] The starting end of the chamfered surface 4 is 1 / 2 of the distance from the center of the working copper plate 1 to the two sides.

[0042] Said connector is provided with a cylindrical boss 33 on the back of said working copper plate 1 , said cylindrical boss 33 is designed integrally with said working copper plate 1 , and said cylindrical boss 33 is provided with a screw thread 35 .

[0043] The protrusio...

Embodiment 2

[0047] It differs from Embodiment 1 in that:

[0048] The angle α between the chamfered surface and the horizontal plane of the 4 working copper plates is 25°.

[0049] The 4 starting ends of the chamfered surface are 2 / 3 of the distance from the center of the working copper plate to the two sides.

[0050] Said connector is provided with a cylindrical boss 33 on the back of said working copper plate 1 , said cylindrical boss 33 is designed integrally with said working copper plate 1 , and said cylindrical boss 33 is provided with a screw thread 35 .

[0051] The protrusion of the connector 3 is a cylinder 32b sleeved on the cylindrical boss.

[0052] A guide hole is provided on the cylinder 32b.

[0053] Arranging the diversion hole on the cylinder can make the coolant flow therein, take away the heat on the cylindrical boss and the cylinder, speed up the heat dissipation surface, and reduce the resistance of the coolant.

Embodiment 3

[0055] The difference from the second embodiment is that the angle α between the chamfered surface 4 and the horizontal plane of the working copper plate is 30°.

[0056] The starting end of the chamfered surface 4 is 3 / 5 of the distance from the center of the working copper plate to the two sides.

[0057] Said connector is provided with a cylindrical boss 33 on the back of said working copper plate 1 , said cylindrical boss 33 is designed integrally with said working copper plate 1 , and said cylindrical boss 33 is provided with a screw thread 35 .

[0058] The protrusion of the connector 3 is a cylinder 32b sleeved on the cylindrical boss.

[0059] A guide hole is provided on the cylinder 32b.

[0060] A circular hole 34 is arranged radially at the upper thread of the cylindrical boss 33 .

[0061] An assembly hole 37 communicating with the side of the backboard is provided on the inner wall of the hole on the side of the backboard 2 .

[0062] A rigid tension rope 36 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com