Heat conduction delay part for braking impedor for washing machine using brushless DC motor

A technology of brushed DC motor and braking impedance, which is applied in the field of washing machines, can solve the problems of reducing the safety and reputation of washing machines, thermal deformation of peripheral devices, etc., and achieve the effects of preventing thermal deformation, prolonging life and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the content, features, and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

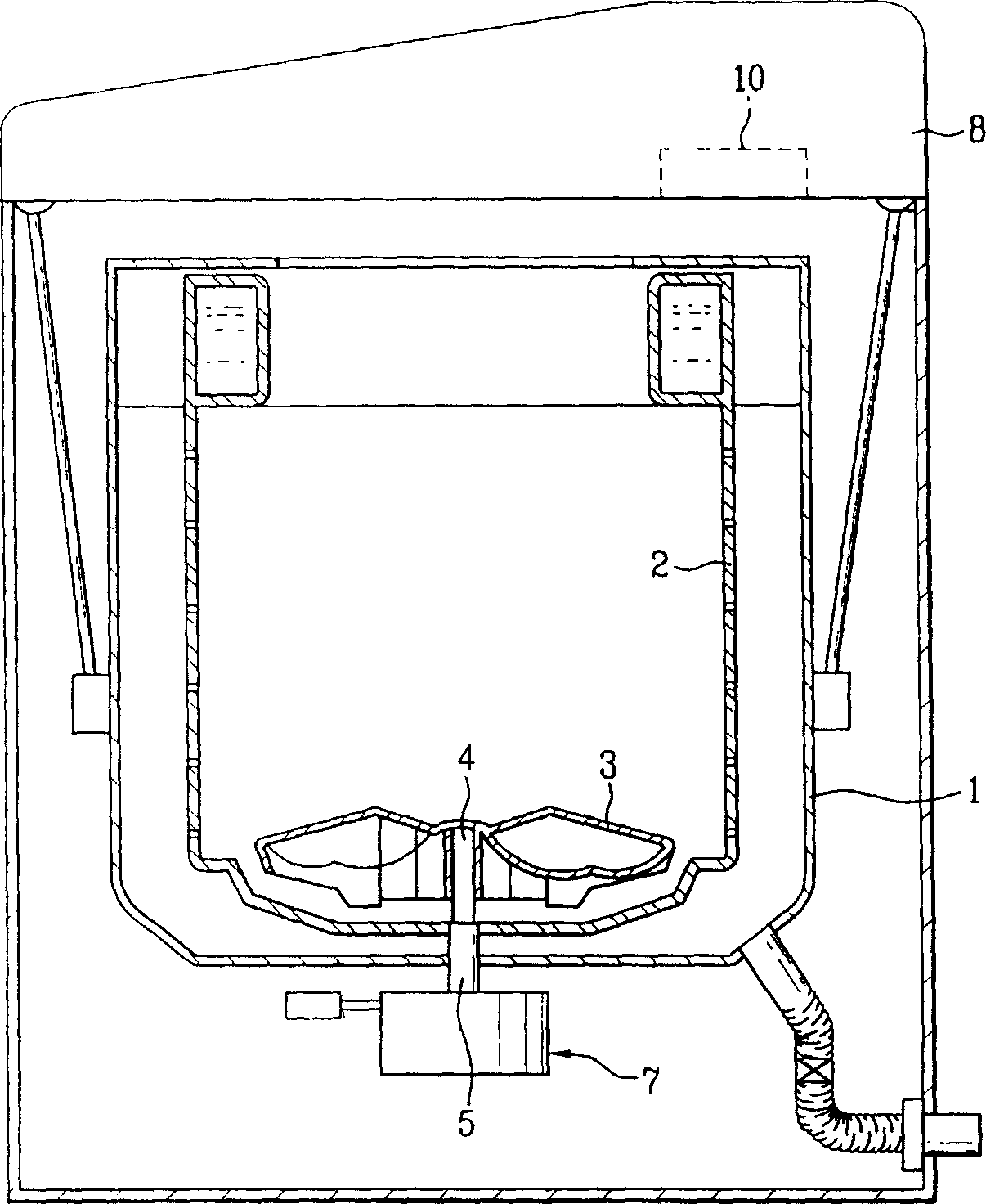

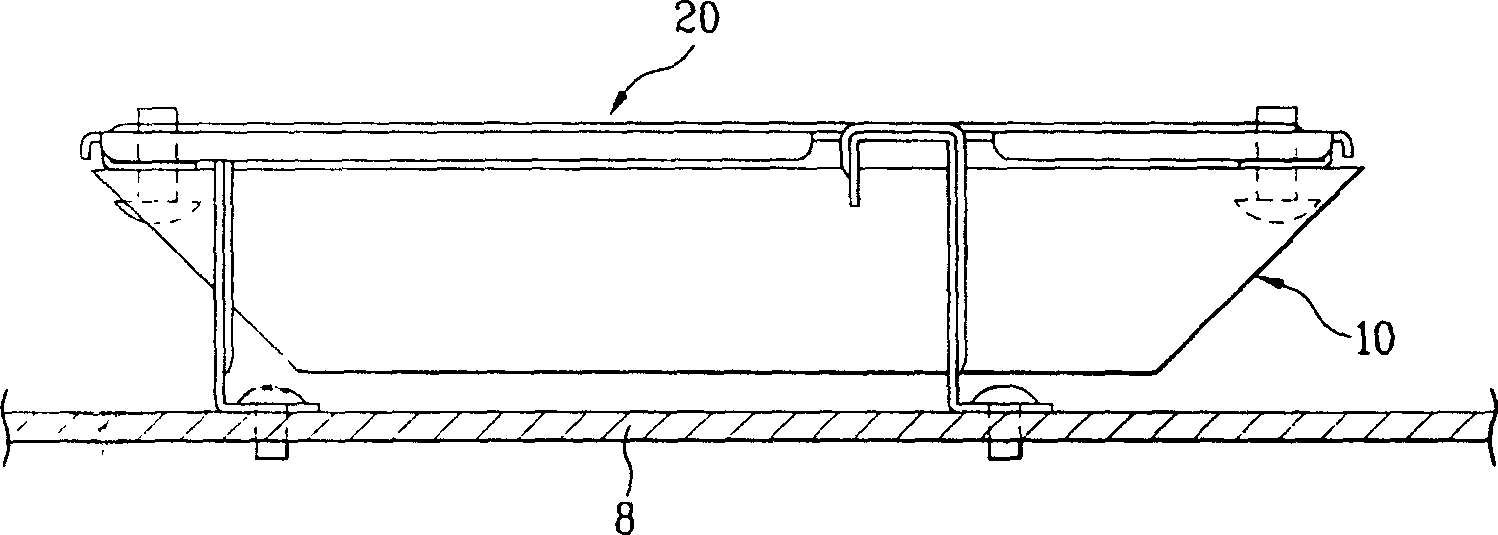

[0028] See image 3 and Figure 4 An example of the present invention will be described in detail.

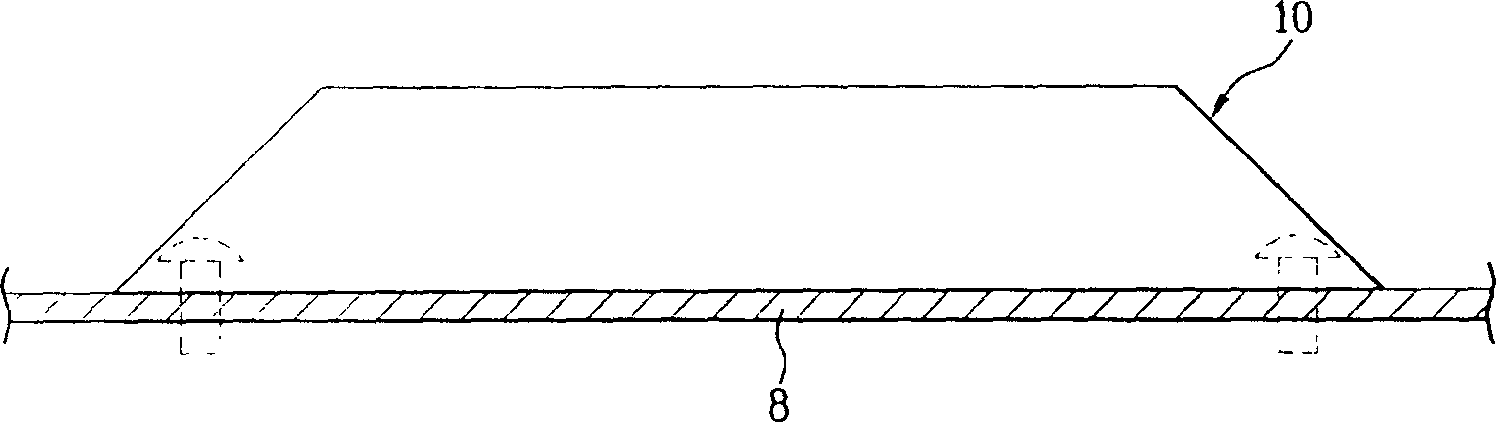

[0029] image 3 It is a cross-sectional view of the thermal conduction delay component of the present invention connected with other components, Figure 4 It is a perspective view of the thermal conduction delay member of the present invention.

[0030] According to an example of the present invention, in a washing machine using a brushless DC motor (7) provided with a brake resistor (10) on the cover (8), the present invention is provided to conduct heat generated by the brake resistor (10) A thermal conduction delay member (20) with a time delay to the peripheral device.

[0031] The thermal conduction delay member (20) includes a fixing frame (200) with a connecting piece (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com