Anti-bubble casting device

A technology of anti-bubble and exhaust device, which is applied in the field of pressure casting or injection mold casting, can solve the problems of high speed and easy generation of pores in castings, achieve stable flow state, high practicability, and increase the actual distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

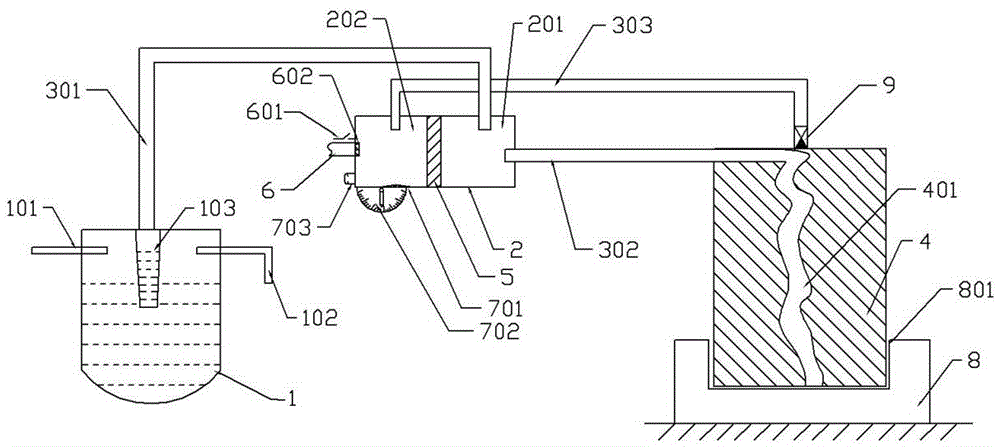

[0014] The reference numerals in the accompanying drawings of the description include: crucible 1, air inlet pipe 101, air outlet pipe 102, liquid lifting pipe 103, pressure chamber 2, first chamber 201, second chamber 202, first pipe 301, second pipe 302, the third pipe 303, mold 4, cavity 401, plunger 5, exhaust device 6, regulating valve 601, filter screen 602, pressure gauge 701, instrument panel 702, alarm 703, vibrating plate 8, groove 801, check valve 9.

[0015] The embodiment is basically as figure 1 As shown: the present invention is an anti-bubble casting device, comprising a crucible 1, a mold 4, a pressure chamber 2, a first pipeline 301, a second pipeline 302 and a third pipeline 303, the top of the crucible 1 is provided with a liquid-raising conduit 103, and the crucible 1 is also An air inlet pipe 101 and an air outlet pipe 102 are provided, a cavity 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com