Gas Expansion Molding Mold

A forming mold and gas expansion technology, which is applied in the manufacture of composite materials and the field of gas expansion forming molds, can solve the problems of unfavorable composite material manufacturing costs, application conditions and environmental restrictions of melting core molds, and shorten the molding cycle and manufacturing costs. , Reduce the difficulty of the process, shorten the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

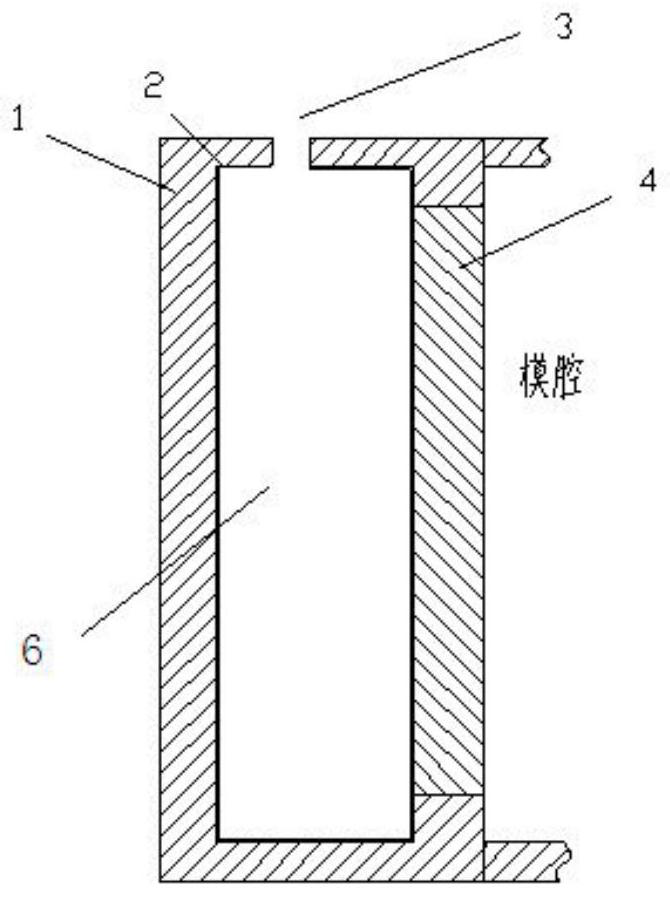

[0068] like Figure 2-3 As shown, the barrel-shaped composite shell was prepared using the hand lay-up process + pressurized form.

[0069] 1) Preparation of raw material preforms, use glass fiber and room temperature epoxy resin to paste product preforms according to the number of layers and structural requirements required by the design;

[0070] 2) Preparation of expansion material fluid, mixing aluminum, hydrochloric acid solution with a mass fraction of 10%, water, and gypsum according to a certain ratio and process requirements, and the mixing time is about 5 minutes;

[0071] 3) The pouring of the material will be as figure 2 The ready-to-use mold shown is cleaned and assembled, with inflatable material poured through the openings, assisted by mechanical vibration;

[0072] 4) Pressurize the core mold and solidify the resin. After the preform is prepared, the mold is closed, and it is controlled to start curing 30 minutes after the expansion material fluid is mixed, ...

Embodiment 2

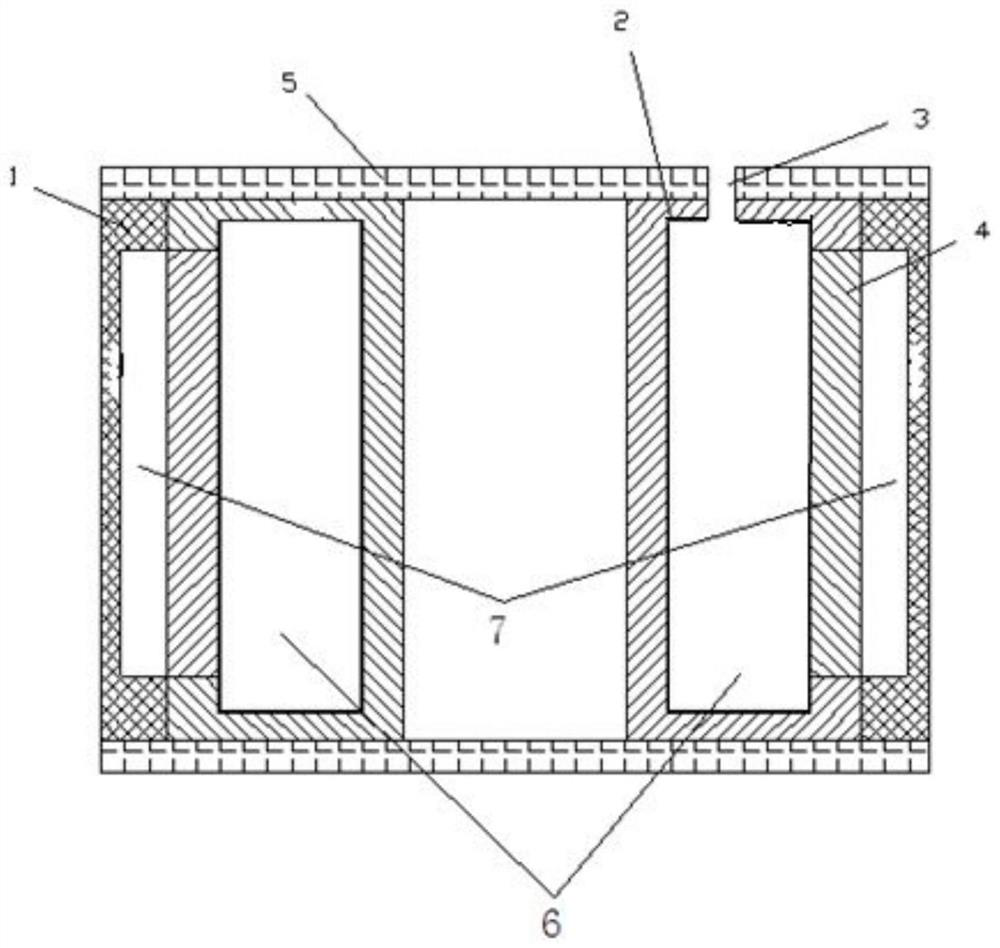

[0076] like Figure 4-5 As shown, a composite box-shaped part is prepared using a prepreg lay-up + molding format.

[0077]1) Preparation of raw material prefabricated parts, using carbon fiber prepreg to lay out product preformed parts according to the number of layers and structural requirements required by the design;

[0078] 2) Preparation of expansive material fluid, mixing aluminum, 40% sulfuric acid solution by mass fraction, gypsum, water, water reducer, retarder, and cement according to a certain ratio and process requirements, and the mixing time is about 5 minutes;

[0079] 3) The pouring of the material will be as Figure 4-5 The ready-to-use mold shown is cleaned and assembled, with expansion material fluid poured through the openings, assisted by mechanical vibrations;

[0080] 4) Forming pressurization and resin curing of the mandrel. After the preformed part is prepared, the mold is closed, placed on the press, and the temperature starts to rise. The tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com