Printing process capable of reducing ink consumption

A processing technology and ink technology, applied in printing, printing post-processing, printing devices, etc., can solve the problems of high ink consumption, etc., and achieve the effects of improving printing efficiency, rapid color formation, and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is further described in detail through specific implementation methods:

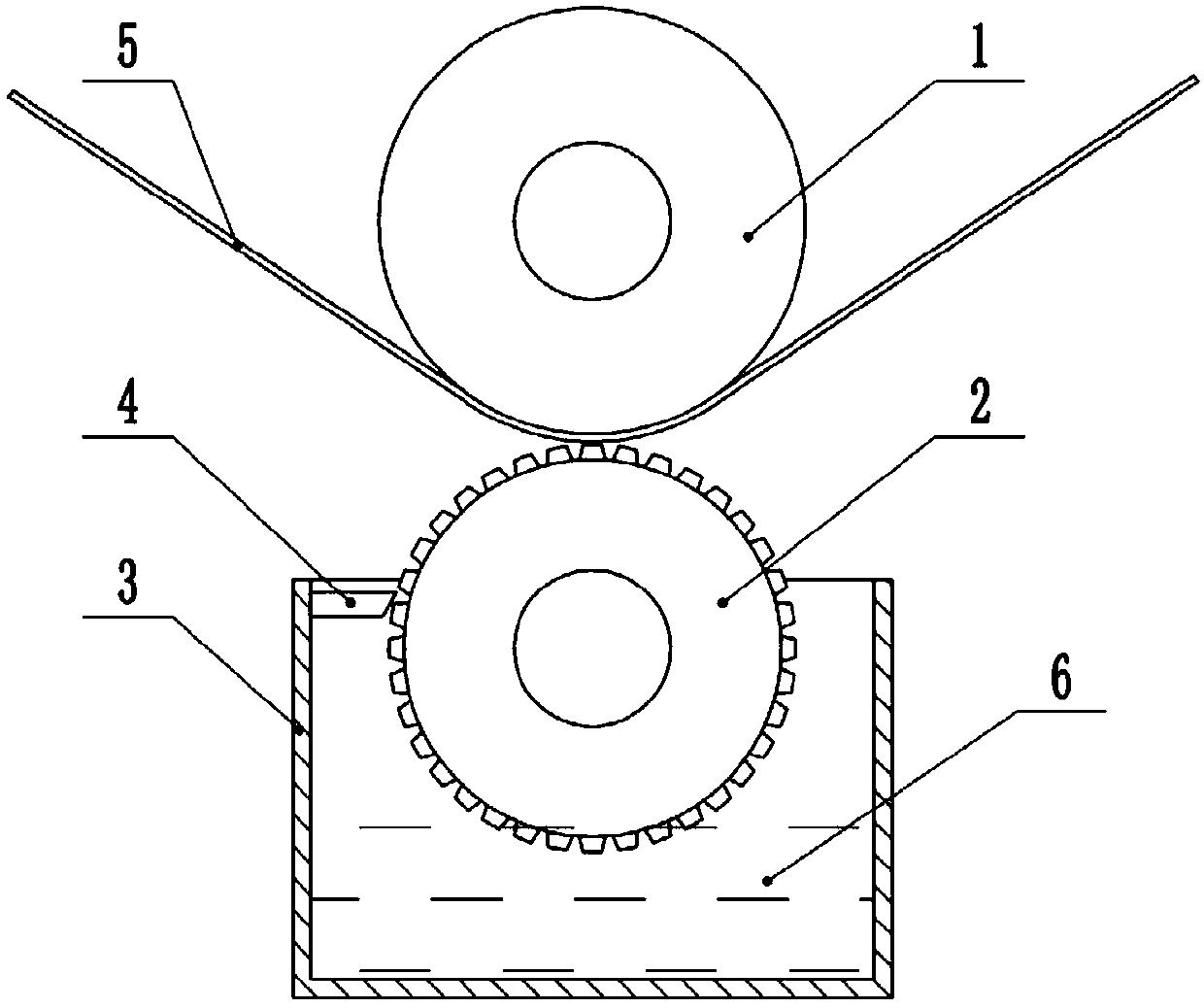

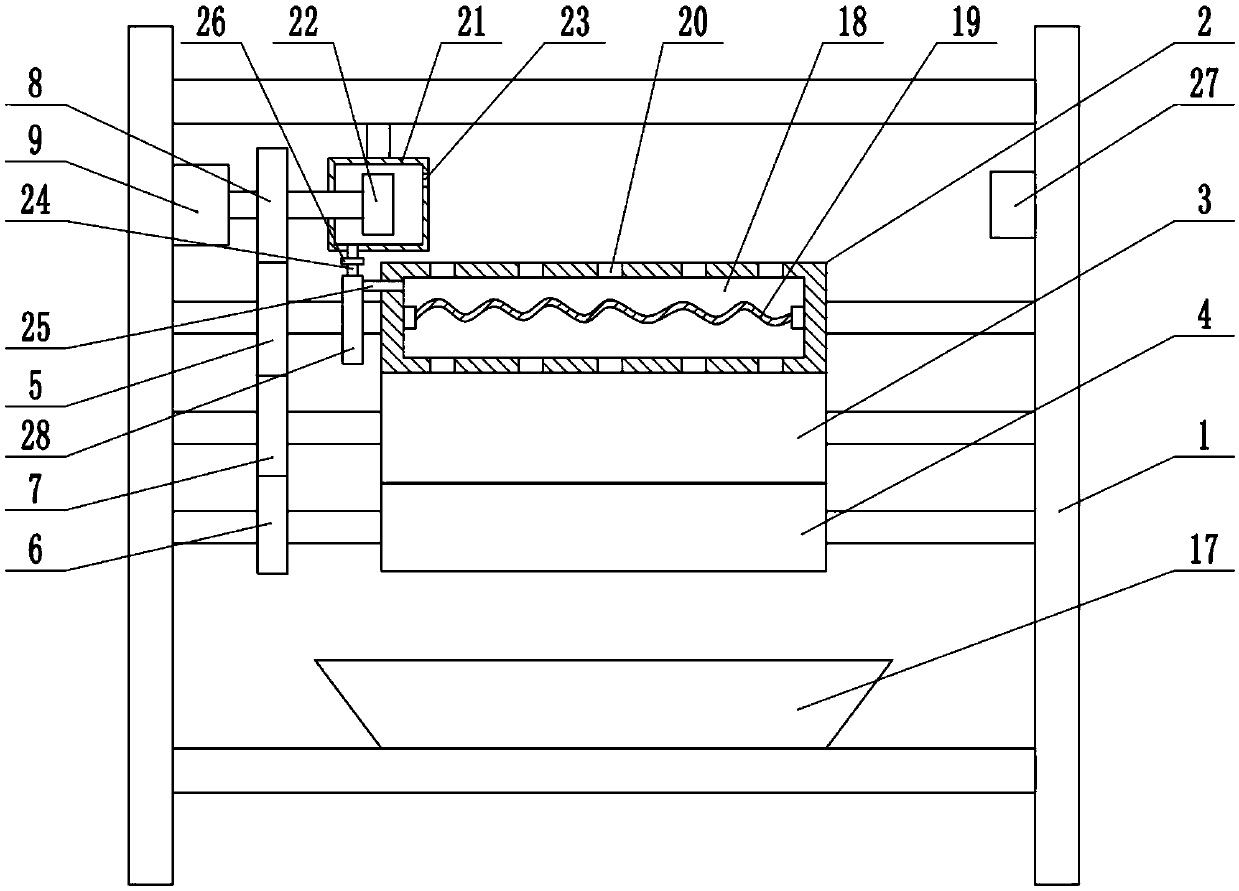

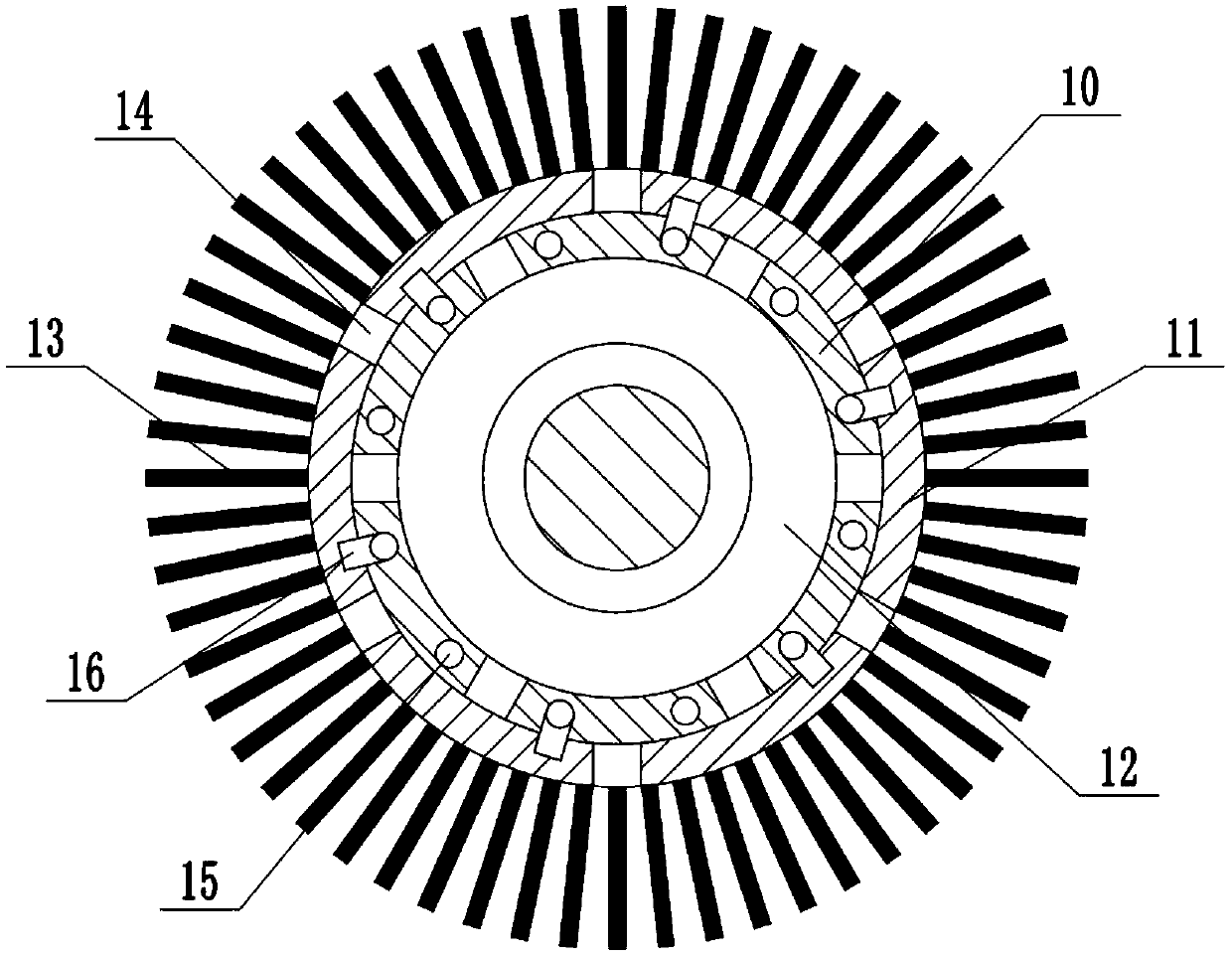

[0030] Instructions attached figure 2 , image 3 The reference signs in include: frame 1, pressure roller 2, plate roller 3, ink roller 4, first gear 5, second gear 6, third gear 7, fourth gear 8, motor 9, inner layer 10 , outer layer 11, inner cavity 12, upper ink brush 13, through hole 14, limit groove 15, limit block 16, recovery groove 17, cavity 18, heating wire 19, air hole 20, bellows 21, negative pressure blade 22 , Air inlet 23, sleeve pipe 24, conduit 25, one-way valve 26, controller 27, ring pipe 28.

[0031] The embodiment is basically as attached figure 2 , image 3 Shown:

[0032] A printing process that can reduce ink consumption requires the use of a printing device, the printing device includes a frame 1, and the frame 1 is rotatably connected with a pressure roller 2, a plate roller 3 that is offset against the pressure roller 2, and a plate roller 3 The off...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com