External-wire-based plasticizer cable concealed winding device

A wire take-up device and hidden technology, applied in the field of electric power, can solve the problems of increasing the space occupied by cables and easy pulling of plasticizer cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

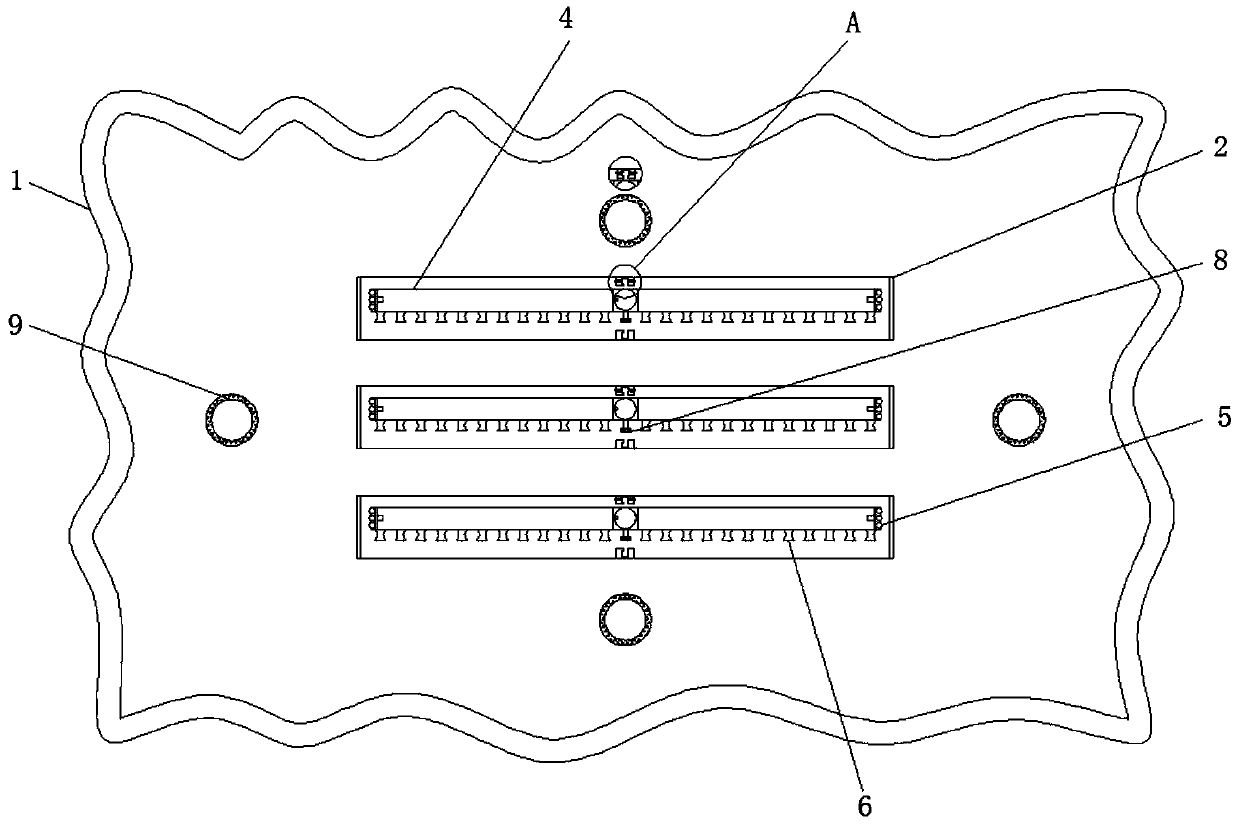

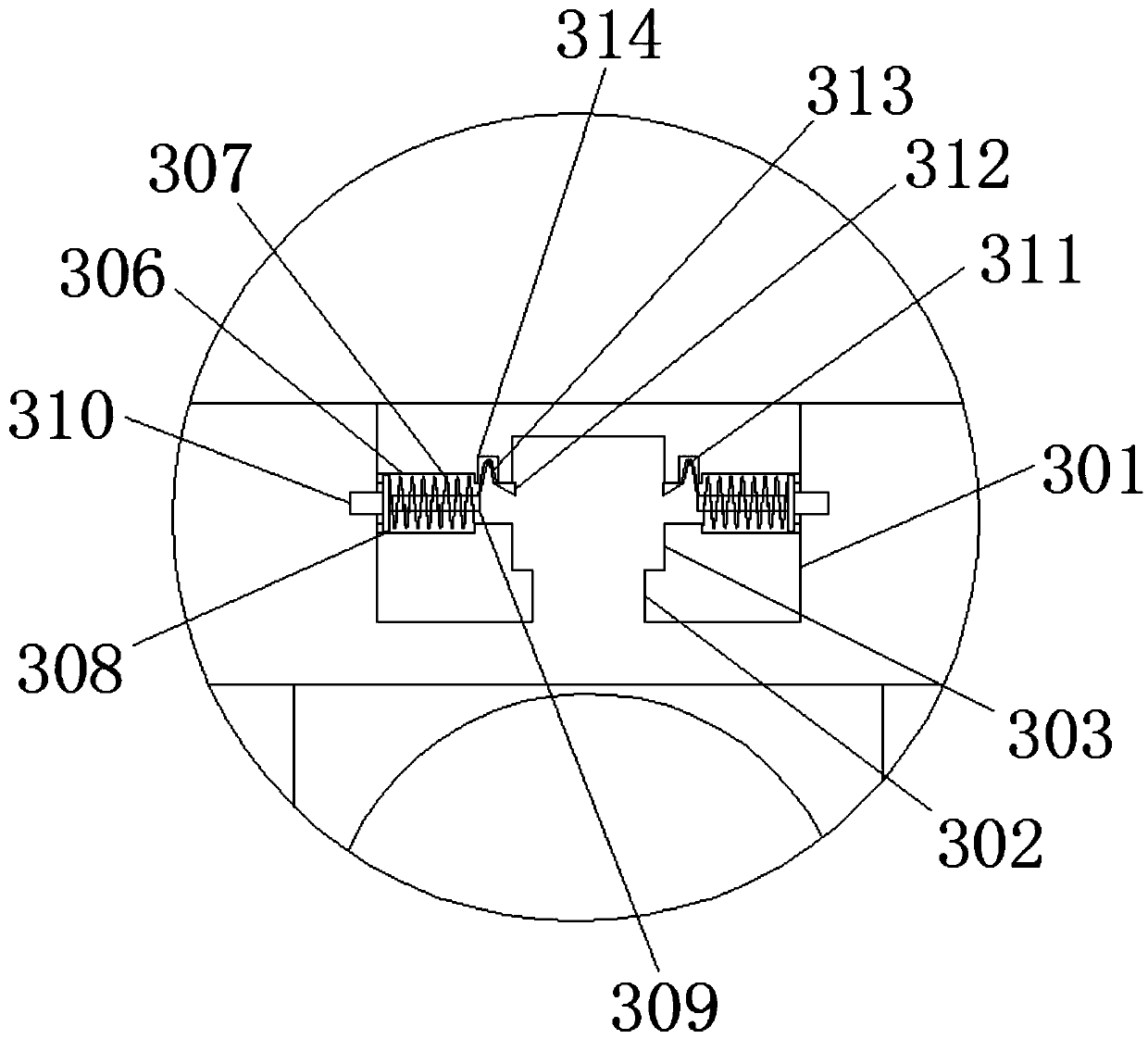

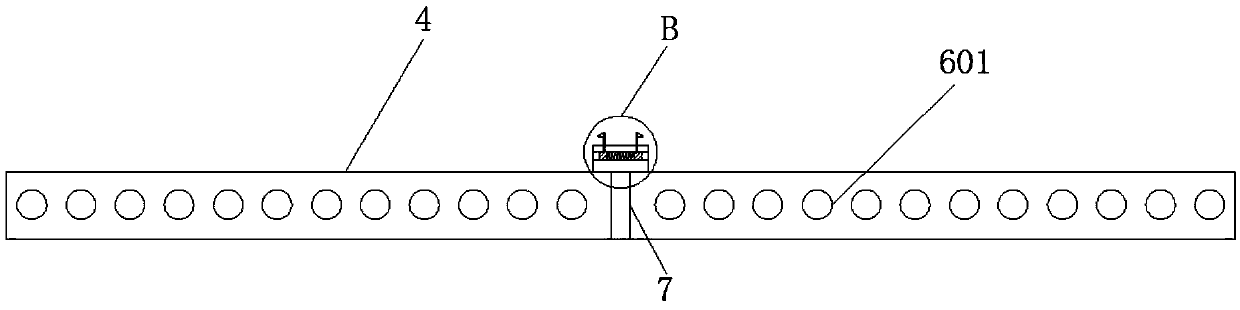

[0042] Such as Figure 1-6 As shown, the embodiment of the present invention provides a plasticizer cable concealed wire take-up device based on external wiring, which includes a wire take-up plate 1. The front side of the wire take-up plate 1 is equally spaced with semi-circular arc transverse grooves 2 and semi-circular. The middle of the inner wall of the arc transverse groove 2 is welded with a turning path reversing mechanism 3, the inner side of the semi-circular arc transverse groove 2 is provided with a winding plate 4, and the middle of the front of the winding plate 4 is provided with a round hole. A wire hole 11 is provided. The inner wall of the circular hole is fixedly connected with a circular ring frame 10, the inner side of the circular ring frame 10 is provided with a circular groove 11, both sides of the winding plate 4 are installed with a bending winding assembly 5, a winding plate 3 The bottom of the wire take-up plate 1 is fixedly connected with a horizont...

Embodiment 2

[0051] A plasticizer cable concealed wire take-up device based on external wiring, including a wire take-up plate 1. The front of the wire take-up plate 1 is equally spaced with semi-circular arc transverse grooves 2, and the middle of the inner wall of the semi-circular arc transverse groove 2 is welded with a whirling In the path turning mechanism 3, the inner side of the semi-circular arc transverse groove 2 is provided with a winding plate 4, the middle of the front of the winding plate 4 is provided with a circular hole, and the back of both sides of the inner wall of the circular hole is provided with a wire hole 11, and the inner wall of the circular hole The ring frame 10 is fixedly connected with a ring groove 11 on the inner side of the ring frame 10, curved winding components 5 are installed on both sides of the winding plate 4, and the bottom of the winding plate 3 is fixedly connected with a horizontal wiring assembly 6 , The back of the middle of the bottom surface...

Embodiment 3

[0060] A plasticizer cable concealed wire take-up device based on external wiring, including a wire take-up plate 1. The front of the wire take-up plate 1 is equally spaced with semi-circular arc transverse grooves 2, and the middle of the inner wall of the semi-circular arc transverse groove 2 is welded with a whirling In the path turning mechanism 3, the inner side of the semi-circular arc transverse groove 2 is provided with a winding plate 4, the middle of the front of the winding plate 4 is provided with a circular hole, and the back of both sides of the inner wall of the circular hole is provided with a wire hole 11, and the inner wall of the circular hole The ring frame 10 is fixedly connected with a ring groove 11 on the inner side of the ring frame 10, curved winding components 5 are installed on both sides of the winding plate 4, and the bottom of the winding plate 3 is fixedly connected with a horizontal wiring assembly 6 , The back of the middle of the bottom surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com