Novel dust collection carding machine

A technology for carding machines and vacuum cleaners, which is applied in deburring devices, textiles and papermaking, fiber processing, etc. It can solve the problems of scattering, dirty workshop environment, inconvenient cleaning, etc., so as to avoid scattering and prevent the workshop environment from being affected Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

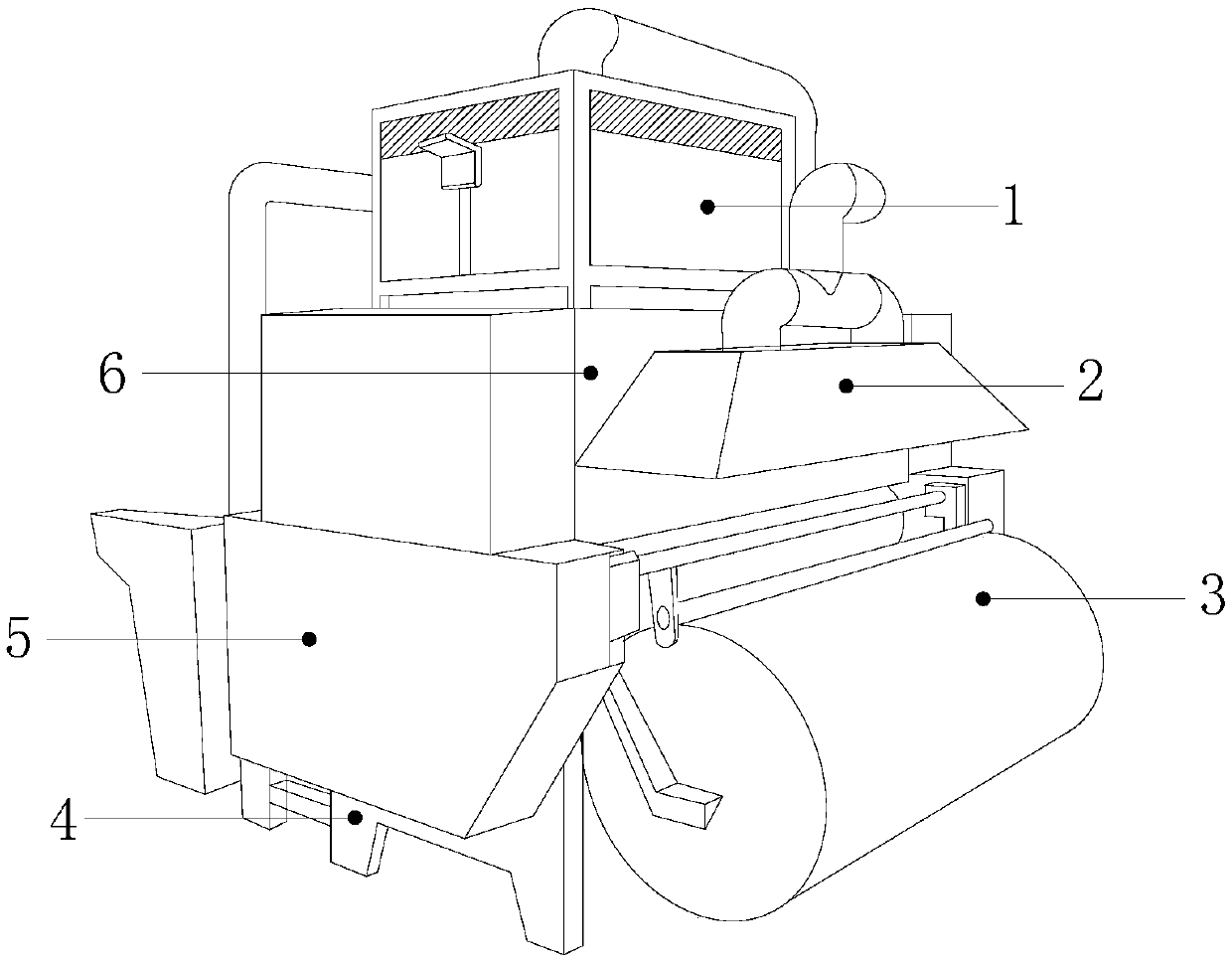

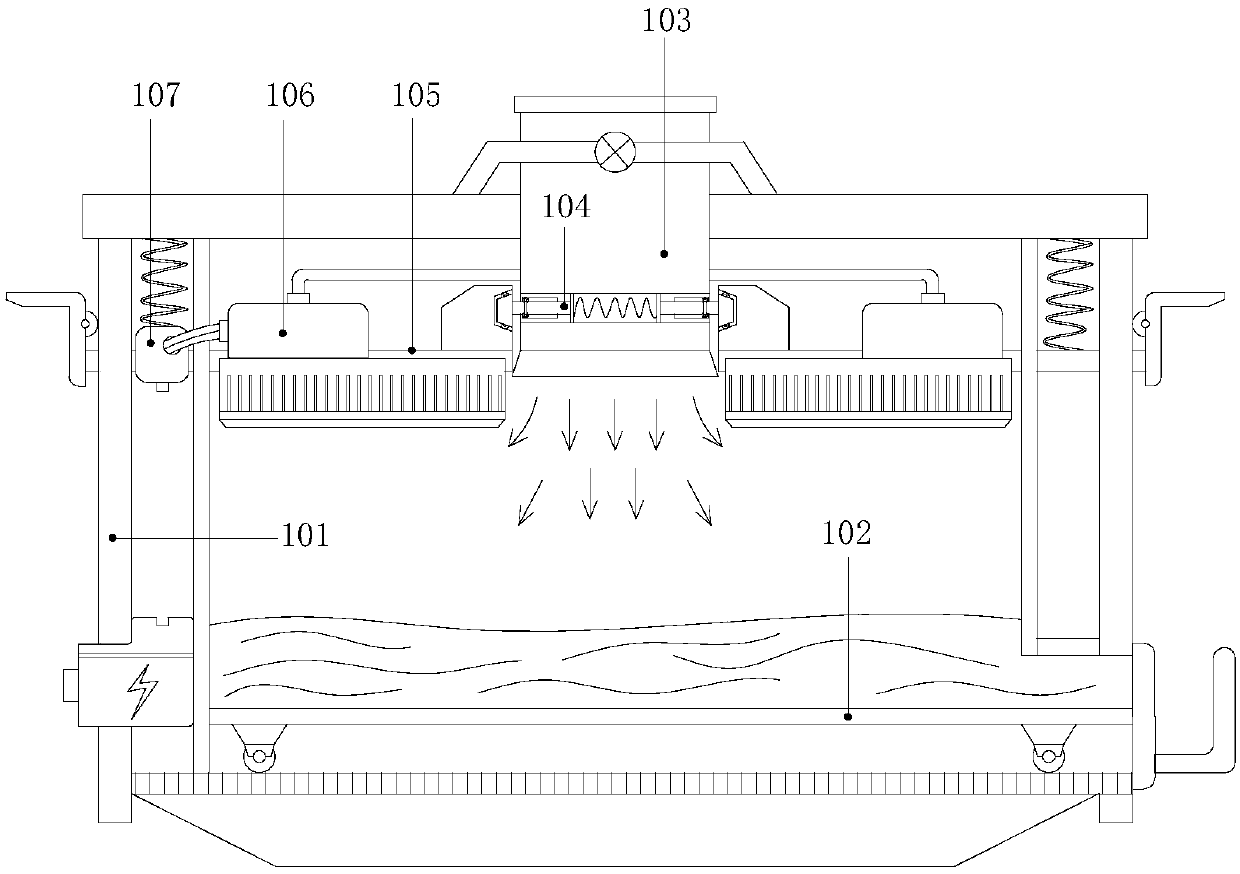

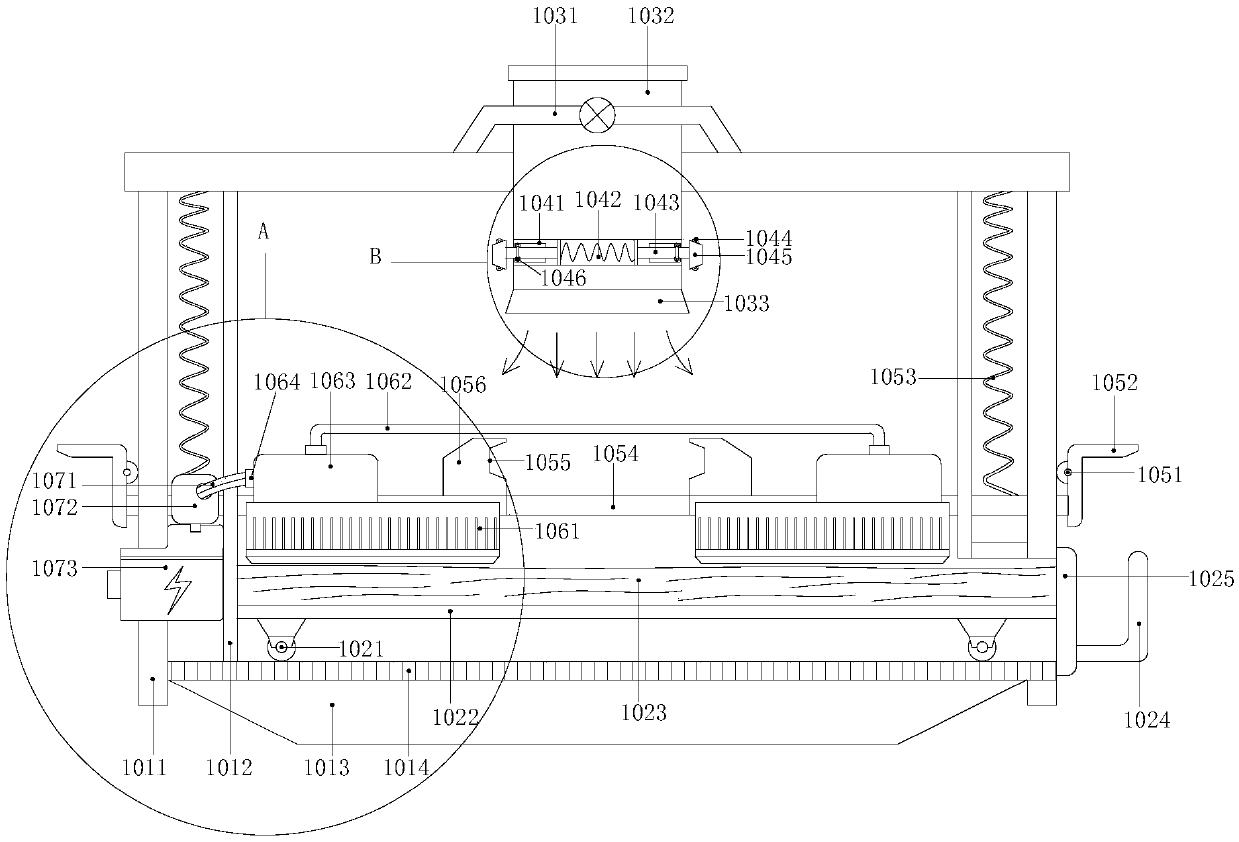

[0022] see Figure 1-Figure 5, the present invention provides a novel vacuum carding machine, the structure of which includes a collection box 1, a vacuum cleaner 2, a cotton roller 3, a bottom bracket 4, a control host 5, and a carding bin 6, and the bottom bracket 4 is installed by buckling At the bottom of the carding bin 6, the left and right ends of the carding bin 6 are respectively provided with a control host 5, and the cotton roller 3 is arranged at the front end of the carding bin 6 surface, and a vacuum cleaner 2 is arranged at the upper end of the surface, and the suction The upper end of the dust machine 2 is fastened with the right end of the collection box 1, and the bottom of the collection box 1 is installed on the top of the carding bin 6 by fitting. Mechanism 104, lifting device 105, heating device 106, conductive mechanism 107, the connection device 103 is installed in the middle of the upper end of the main body 101 by snap-fitting, and a positioning mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com