Lens drive motor, camera and mobile terminal device

A lens driving and mobile terminal technology, which is applied in the field of cameras and mobile terminal devices, and lens driving motors, can solve the problems of difficult balance between driving force and linear stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

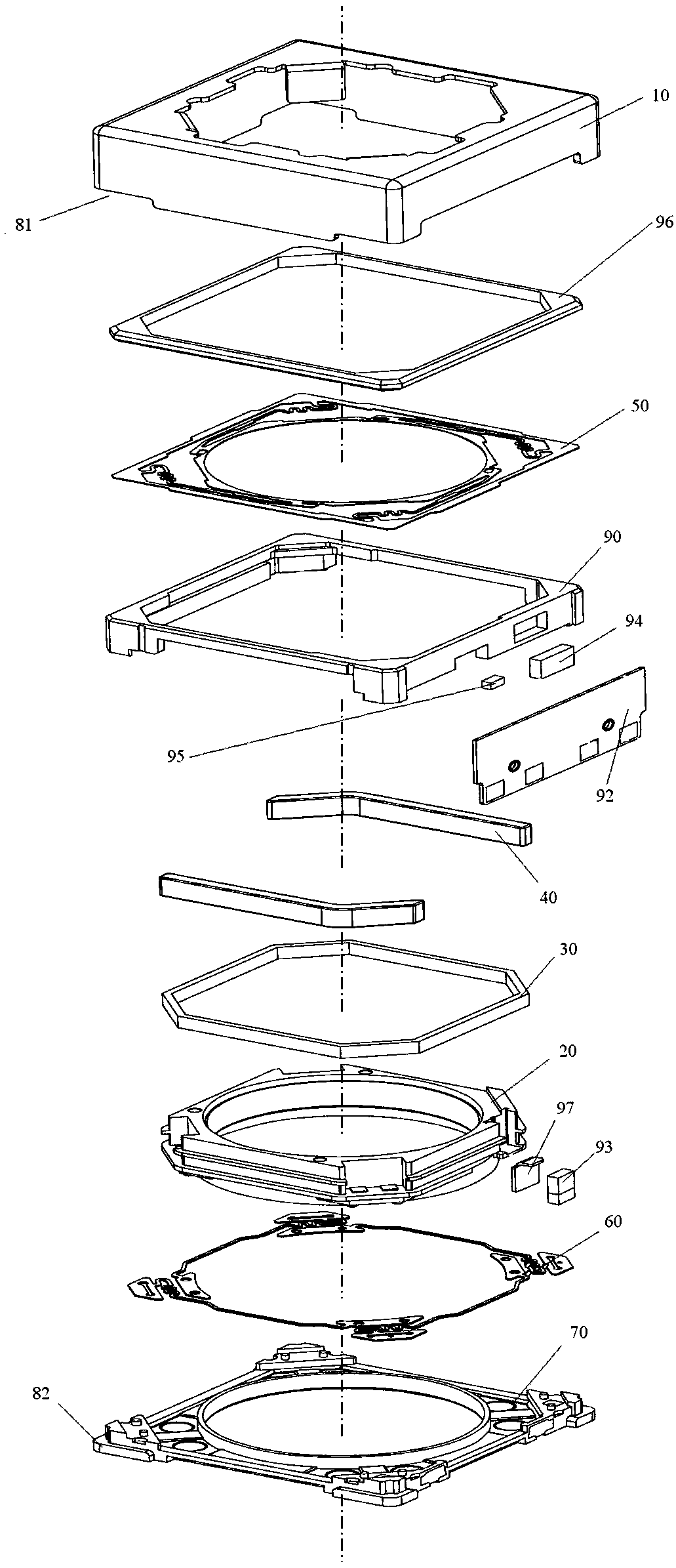

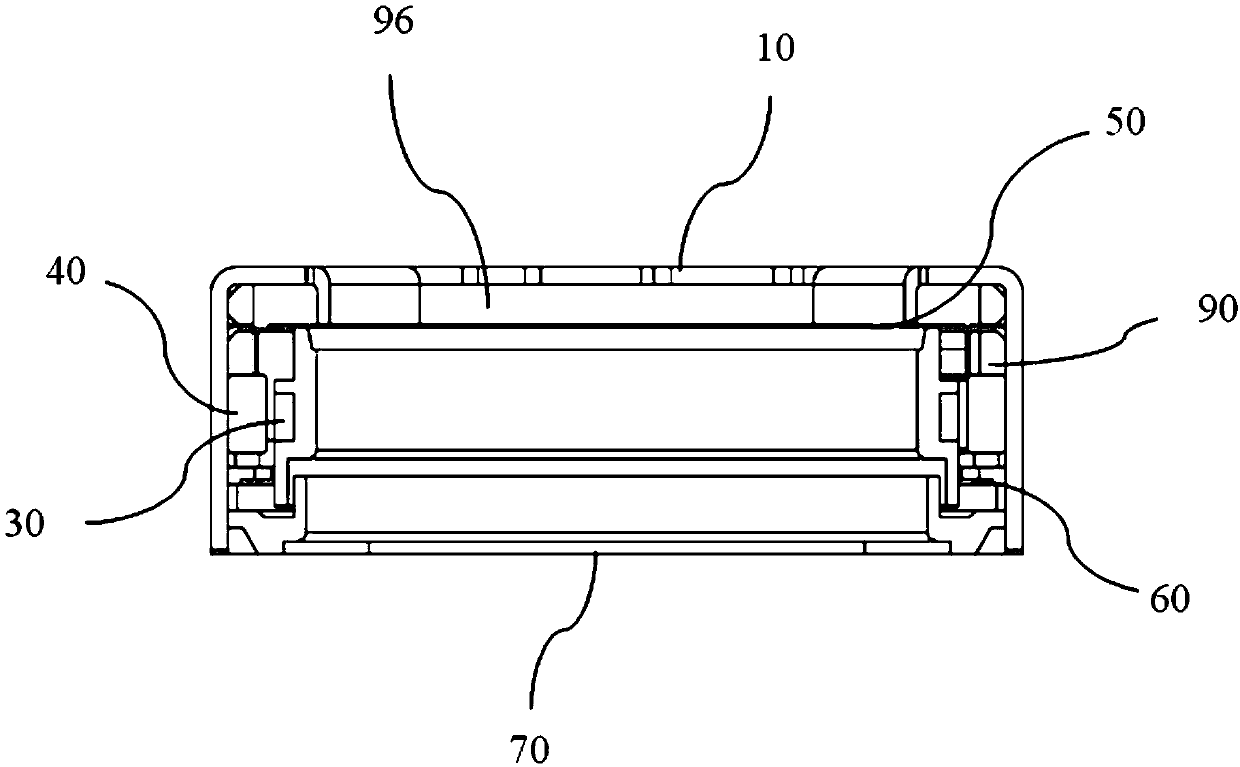

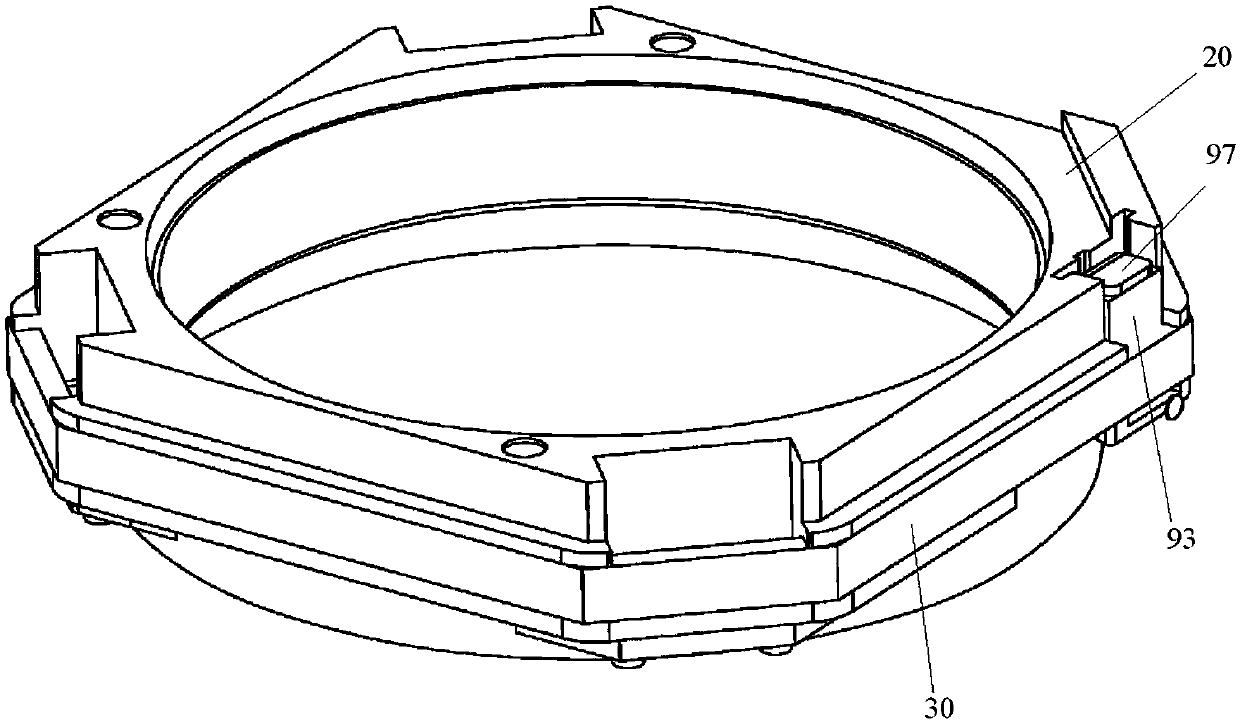

[0049] Such as Figure 1 to Figure 10 As shown, the lens driving motor includes a casing 10, a lens support body 20, a coil 30 and a magnet assembly 40. The coil 30 is wound on the lens support body 20 and is arranged in the casing 10. The magnet assembly 40 is arranged between the lens support body 20 and the casing. Between 10. The lens drive motor also includes a Hall chip 94, a Hall magnet 93 and a Hall gasket 97, the Hall chip 94 is arranged on the PCB board 92; the Hall magnet 93 is arranged on the lens support 20 corresponding to the Hall chip 94 on the position; the Hall gasket 97 is arranged between the Hall magnet 93 and the lens support body 20, and the Hall gasket 97 includes a back shield section 971 and a top shield section 972, and the top shield section 972 is formed by the back shield section 971. The top protrudes toward the PCB board 92 to cover the top of the Hall magnet 93 .

[0050] In this way, by setting the top shield section 972 on the Hall gasket 9...

Embodiment 2

[0068] The difference from the first embodiment is that the specific structure of the Hall pad 97 is different from that in the first embodiment.

[0069] Such as Figure 11 and Figure 12 As shown, the Hall spacer 97 also includes a bottom shielding section 973 , and the bottom shielding section 973 protrudes from the bottom of the back shielding section 971 to the PCB 92 to cover the bottom of the Hall magnet 93 . By setting the bottom shielding section 973, the magnetic field shielding effect can be further improved. This setup is perfectly reasonable as long as space within the lens drive motor allows.

[0070] Optionally, at least one of the top shielding section 972 and the bottom shielding section 973 is formed by bending. When the Hall gasket 97 only includes the back shielding section 971 , the top shielding section 972 and the bottom shielding section 973 , it is easier to obtain the desired shape of the Hall gasket 97 by bending and forming. Of course, the Hall ...

Embodiment 3

[0072] The difference from the second embodiment is that the specific structure of the Hall pad 97 is different from that of the second embodiment.

[0073] Such as Figure 13 and Figure 14 As shown, the Hall gasket 97 further includes a side shielding section 974 , and the side shielding section 974 protrudes from the side of the back shielding section 971 to the PCB 92 to cover the side of the Hall magnet 93 . By providing the side shielding section 974, the magnetic field shielding effect can be further improved. This setup is perfectly reasonable as long as space within the lens drive motor allows.

[0074] Optionally, at least one of the top shield segment 972, the bottom shield segment 973 and the side shield segment 974 is bent and formed. By bending and forming, it is easier to obtain the Hall gasket 97 of the desired shape. Of course, the Hall spacer 97 of the desired shape can also be obtained by metal casting.

[0075] When the Hall gasket 97 is manufactured b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com