New anti-overload safety motor

An anti-overload, new technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as motor installation is not smooth, easily damaged load equipment, fixing frame error, etc., to facilitate disassembly, inspection and maintenance, to ensure internal cleanliness, Simple and convenient cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

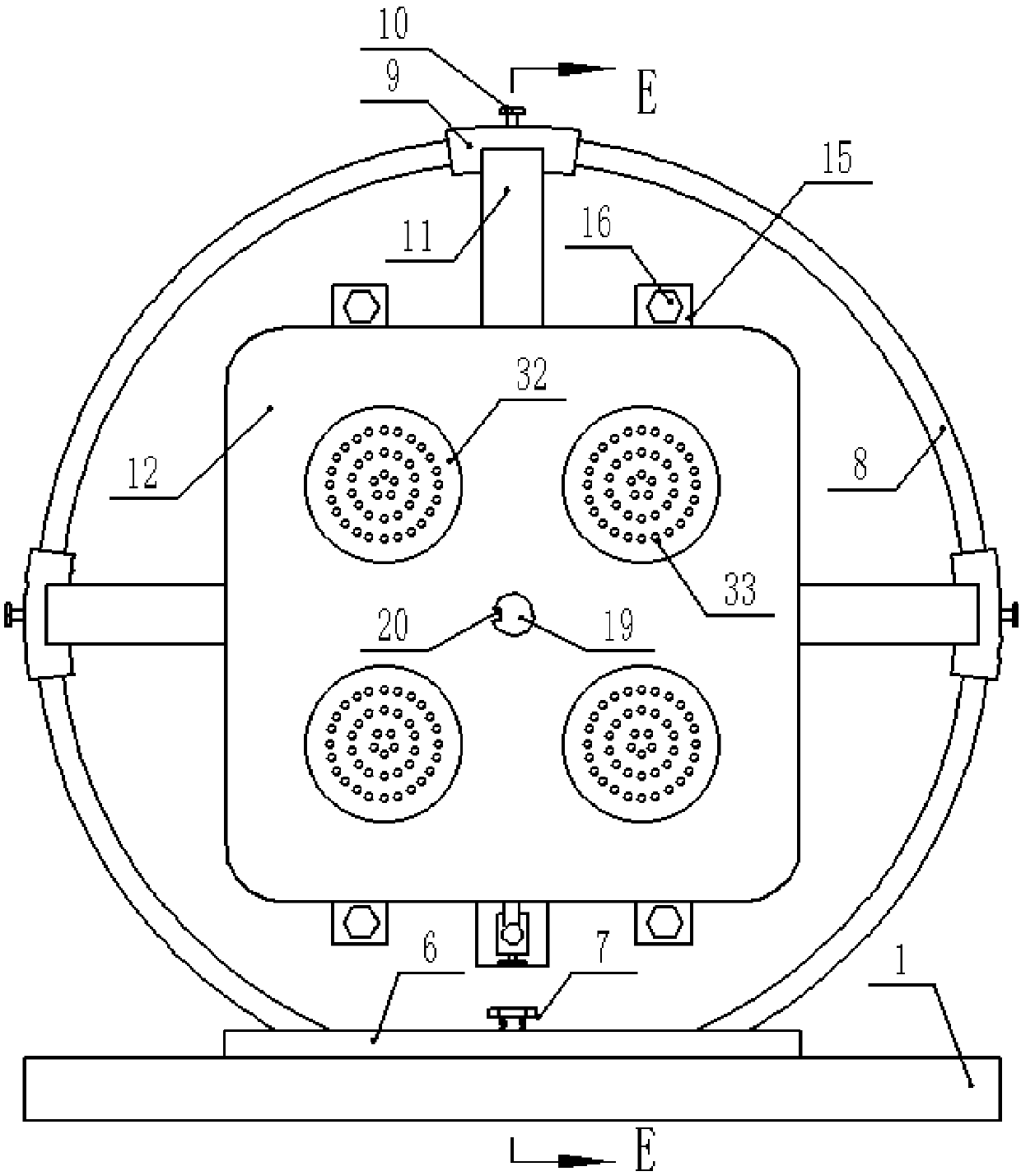

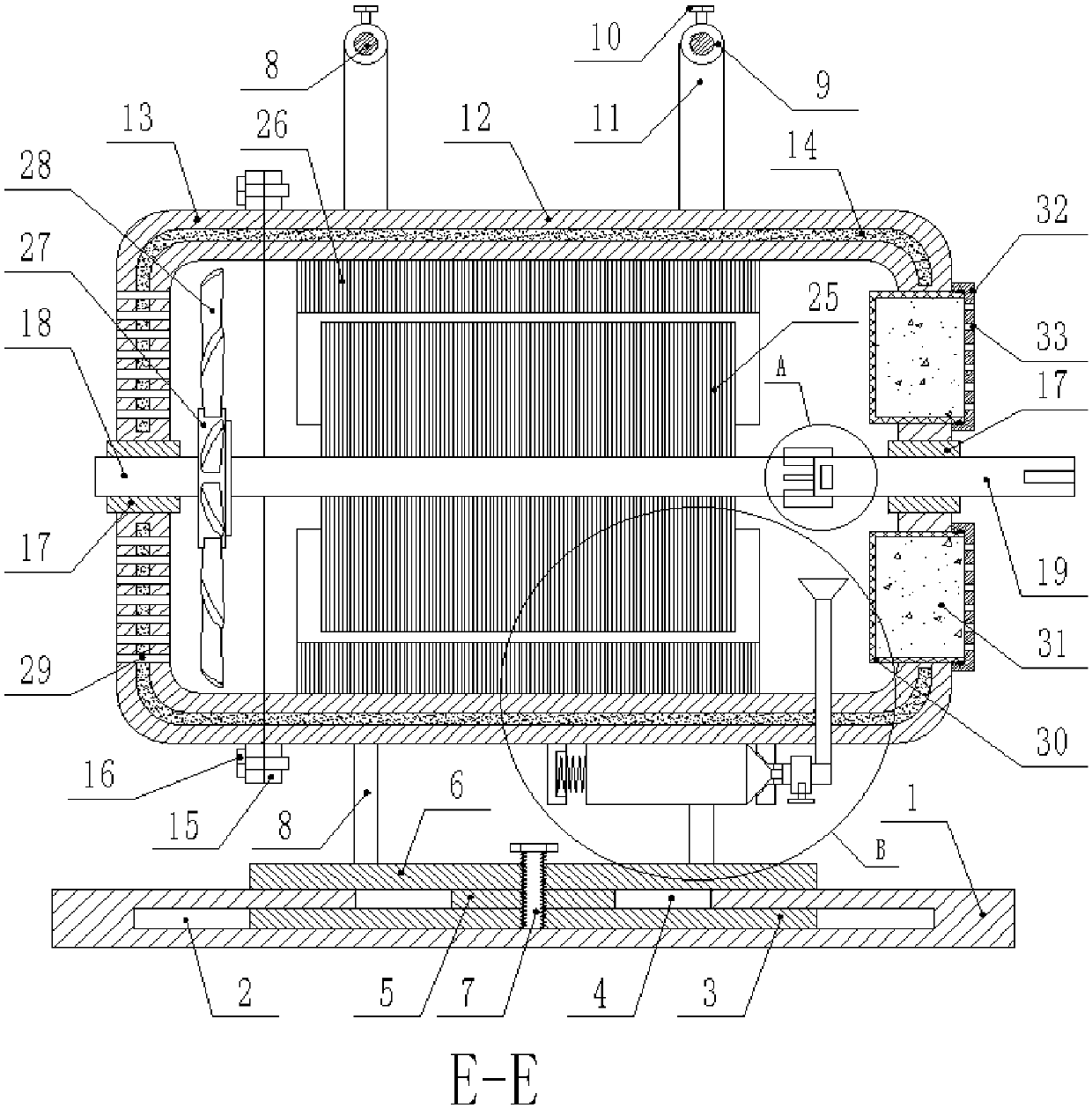

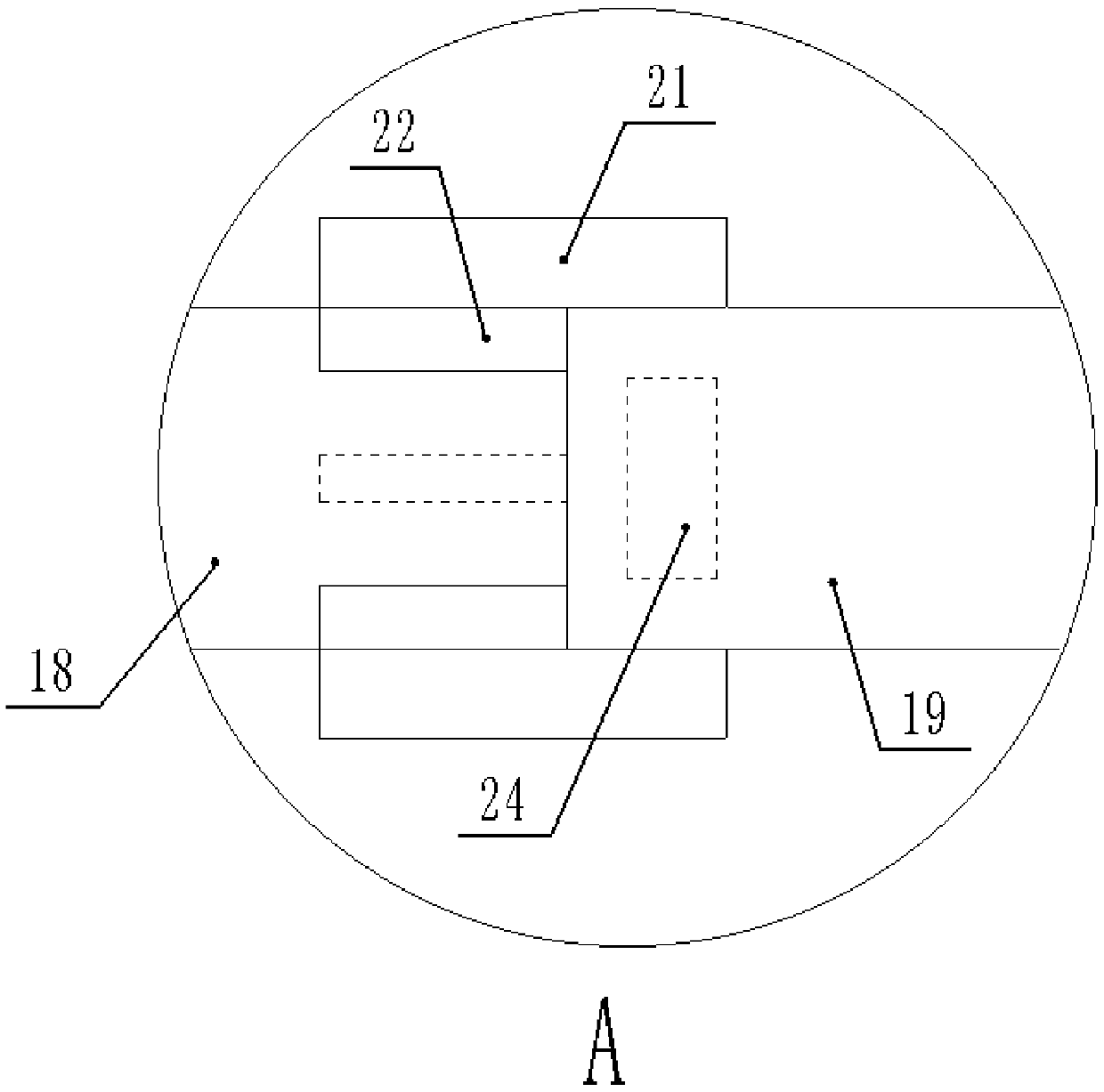

[0026] Such as Figure 1-Figure 6 As shown, a novel anti-overload safety motor includes a fixed plate 1, a circular cavity 2 is provided in the fixed plate 1, and a disc 3 slidingly connected with it is provided in the cavity 2, and the fixed plate 1 A round hole 4 corresponding to the disc 3 is provided in the middle of the upper end of the disc 3, a connecting plate 5 is fixed in the middle of the top of the disc 3, and a top plate 6 that fits with the top surface of the fixing plate 1 is fixed on the top of the connecting plate 5. The middle vertical thread of the top plate 6 is connected with the top plate bolts 7 passing through the connecting plate 5 and the disc 3, the top surface of the top plate 6 is fixed with a ring frame 8, and the ring frame 8 is covered with an arc-shaped sleeve 9 slidingly connected with it. , the arc-shaped slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com