A garbage disposal device for environmental protection

A garbage cleaning and environmental protection technology, applied in grain processing, transportation and packaging, presses, etc., can solve the problems of polluting the environment, single function, no rolling function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

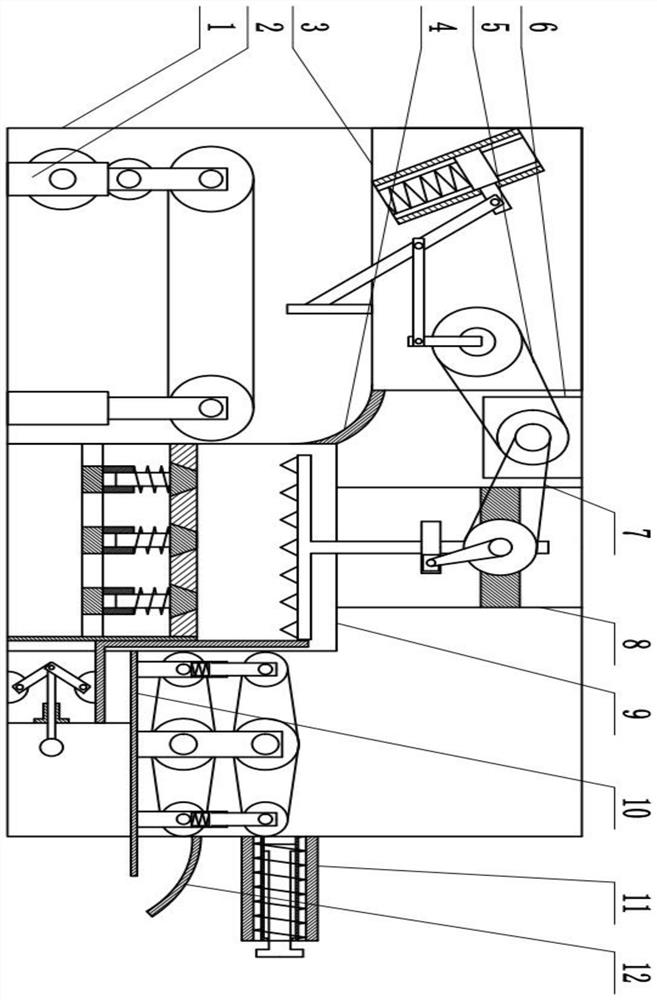

[0034] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11 illustrate this embodiment, the technical problem that the present invention mainly solves is to provide a kind of garbage processing device for environmental protection, comprising shell 1, transmission base 2, push Box 3, limit plate 4, belt Ⅰ 5, motor 6, belt Ⅱ 7, crushing box 8, dry and wet separation box 9, crushing base 10, electromagnet box 11, garbage discharge limit plate 12, which can solve the problem Some garbage disposal devices have a simple structure and a single function. The general treatment method is to bury or incinerate the garbage collected in a centralized manner. The general garbage collection device does not have the problem of rolling function, and some garbage will produce liquid during garbage collection. The liquid will flow out and pollute the environment.

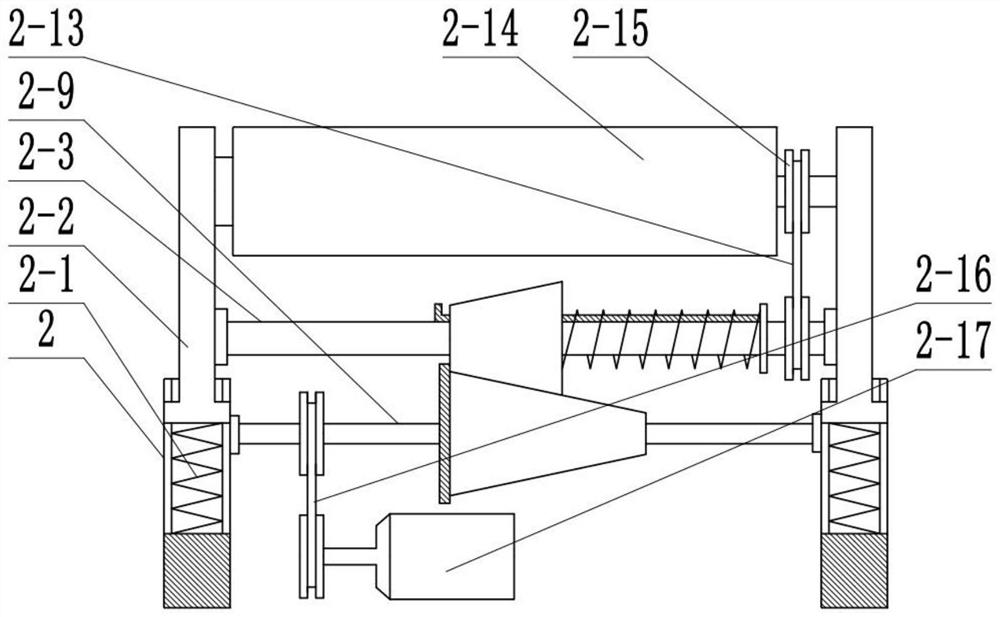

[0035] The upper end of the transmission base 2 is provided with a transmission base spring 2-1, a sliding base 2-2, a small h...

specific Embodiment approach 2

[0043] Combine below figure 1 , 2 . There are two bases 2-2 and two conveying rollers 2-14.

specific Embodiment approach 3

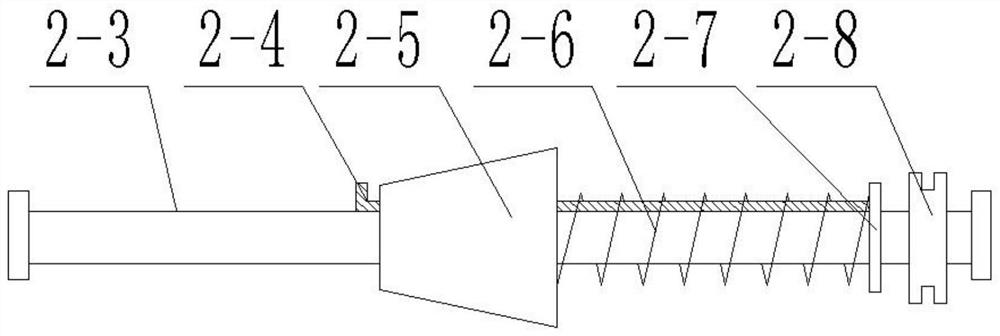

[0045] Combine below figure 1 , 2 . , small helical gear 2-5, small helical gear spring 2-6, small helical gear limit plate 2-7, small helical gear shaft belt pulley 2-8 share the central line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com