Insert for use in an injection molding nozzle and injection molding nozzle with such an insert

A technology for injection nozzles and inserts, applied in the field of inserts used in injection nozzles and injection nozzles with such inserts, to achieve the effects of saving energy costs, ensuring long-term use, and preventing peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] In the processing of thermosetting plastics and elastomer materials in which the plastic hardens under the influence of temperature, cold runner systems are used instead of hot runner systems. Therefore, when describing hot runner systems below, cold runner systems are always referred to, depending on the application and also according to the meaning.

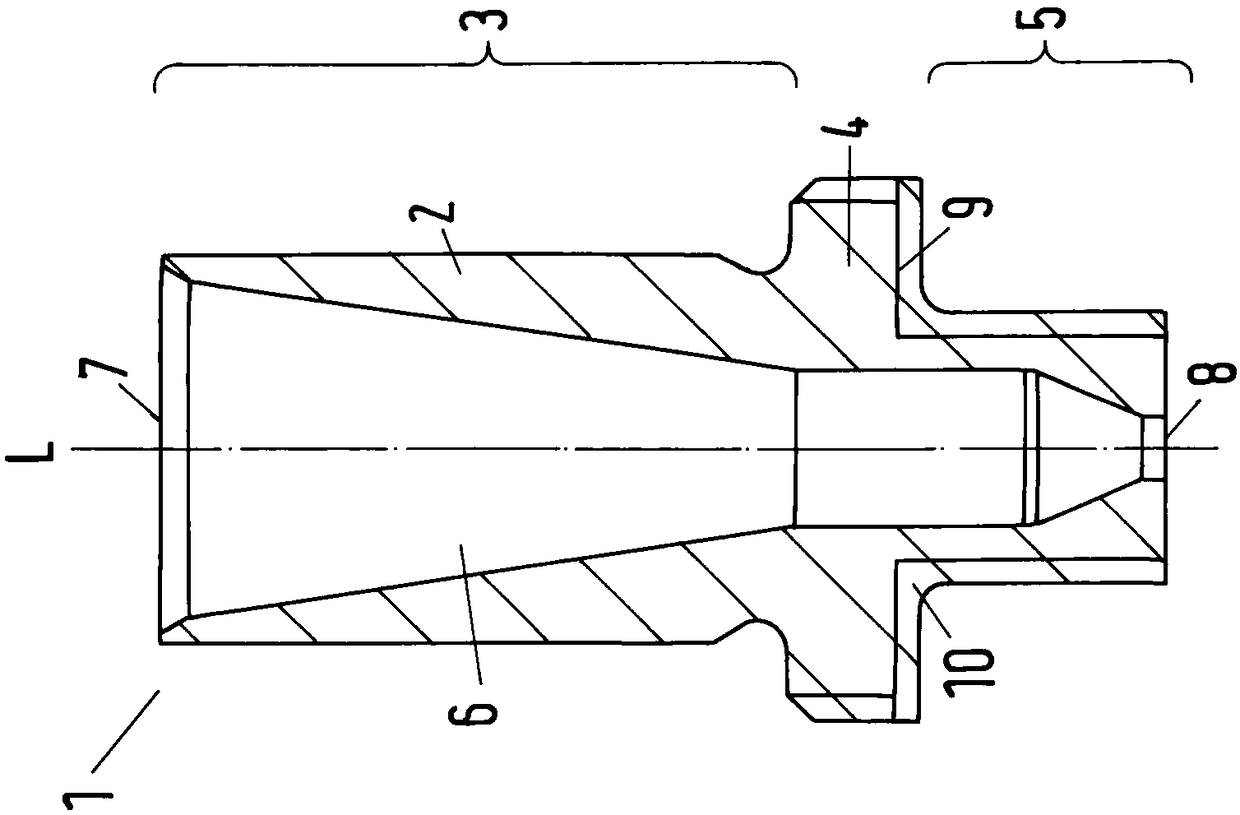

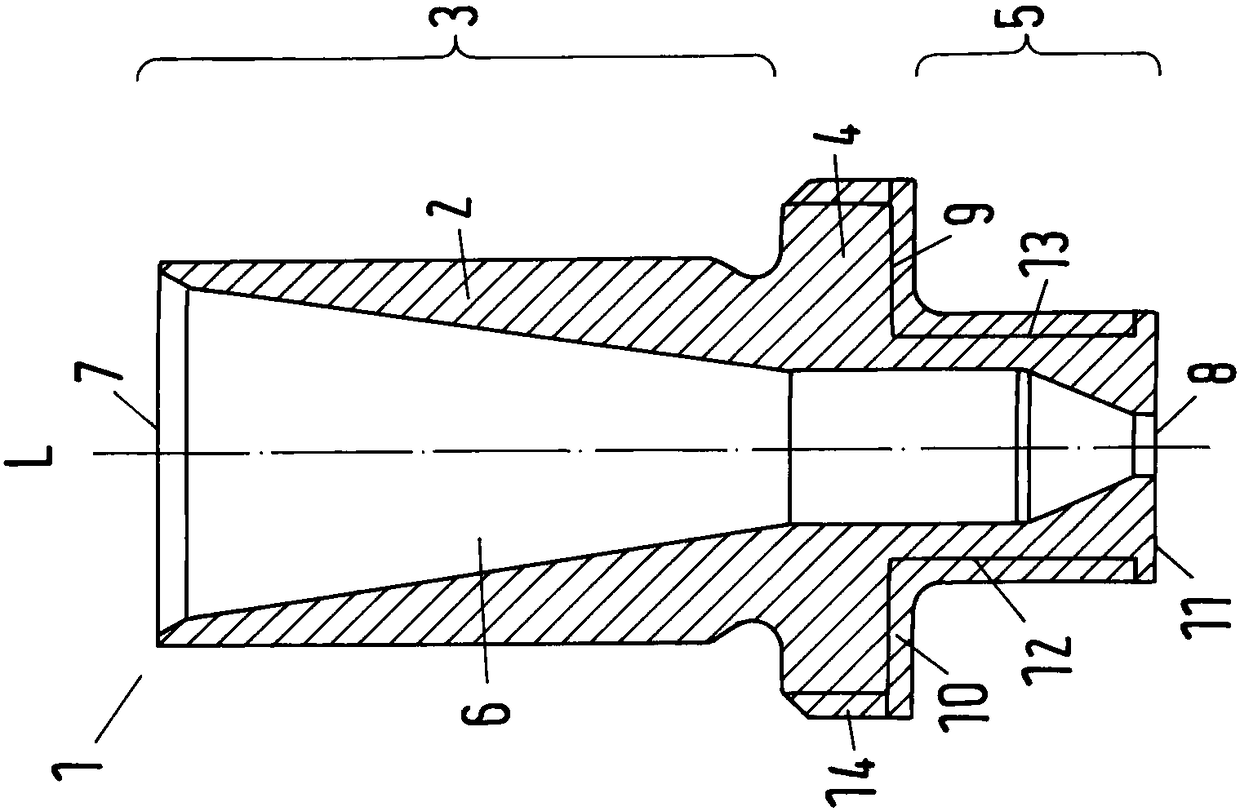

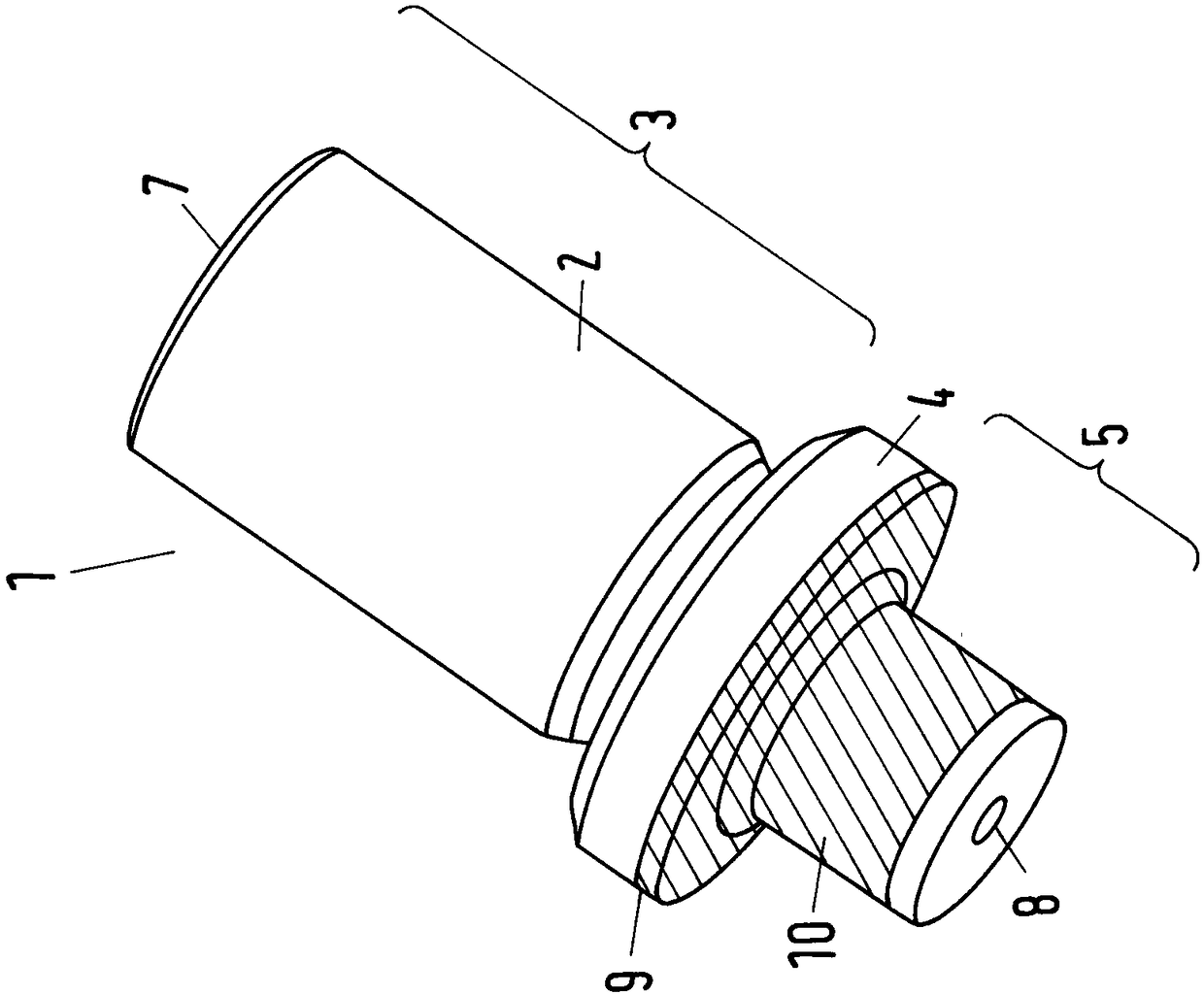

[0089] figure 1 with figure 2 Each shows a longitudinal section through an insert 1 according to the invention for an injection molding nozzle (not shown). The insert 1 is always formed by a corresponding insert body 2 made of a highly thermally conductive material. The insert body 2 here has a neck 3 , a collar 4 and an end 5 . The insert body 2 can be connected with its neck 3 to the injection molding nozzle, for example by being inserted or pushed onto the injection molding nozzle. The flange 4 protrudes radially relative to the neck 3 and the end 5 . The end portion 5 can be inserted into a cavity (not shown) o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com