Vehicle seat component and method of manufacturing the same

A vehicle and seat technology, which is applied in the field of vehicle seat components and their manufacturing, can solve problems such as shape distortion, deterioration of appearance aesthetics, abutment, etc., and achieve the effects of efficient manufacturing and good aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

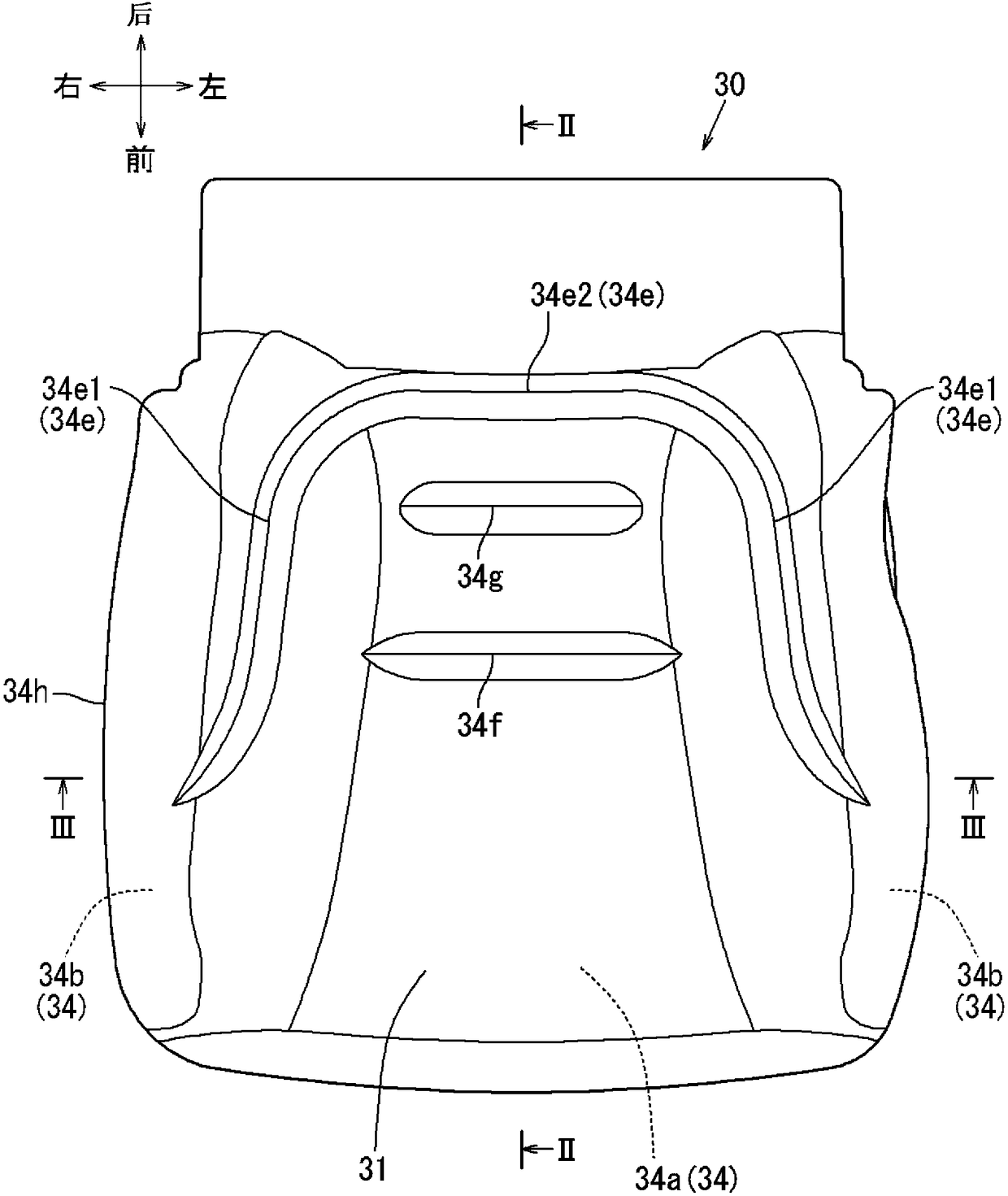

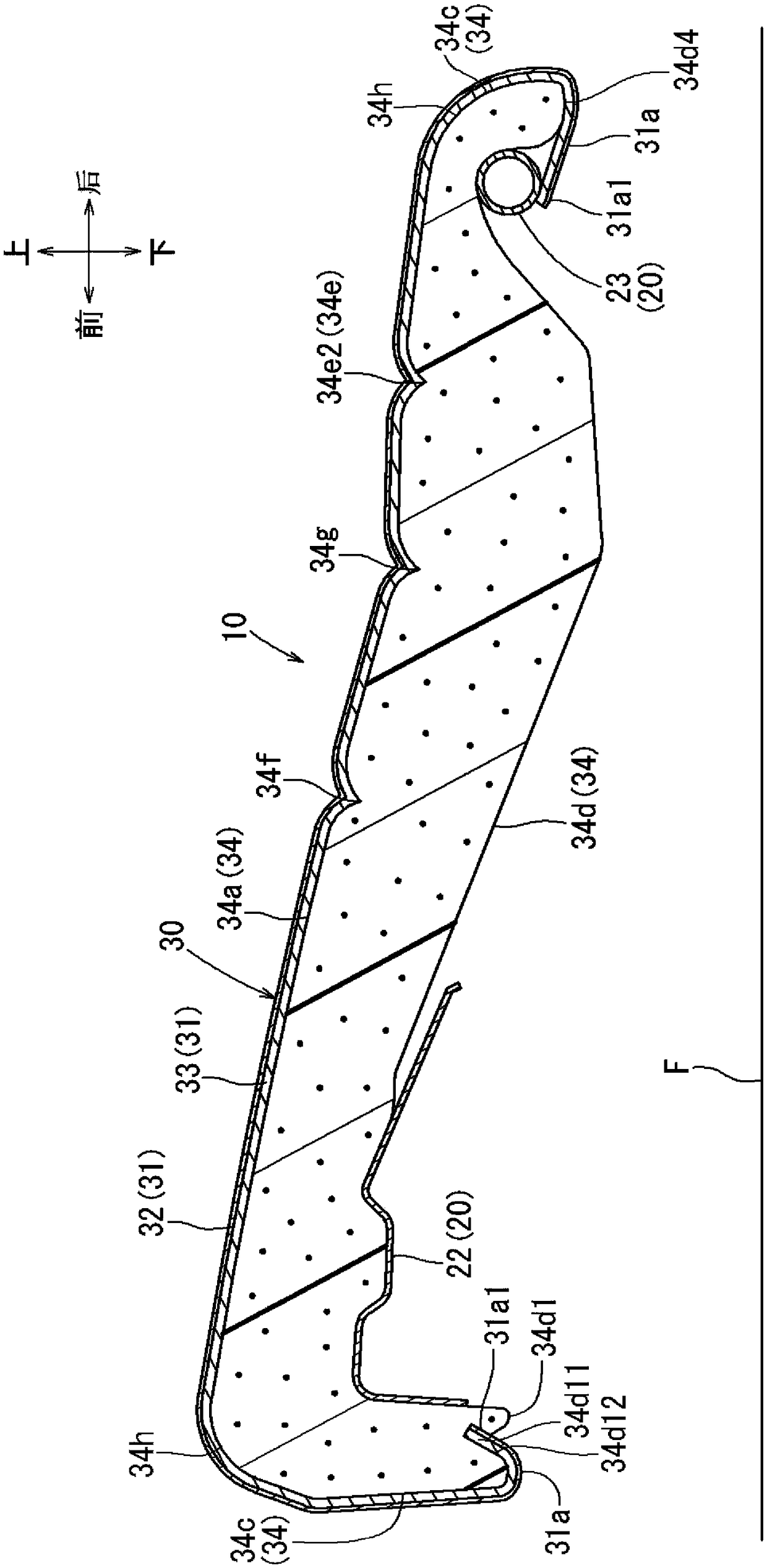

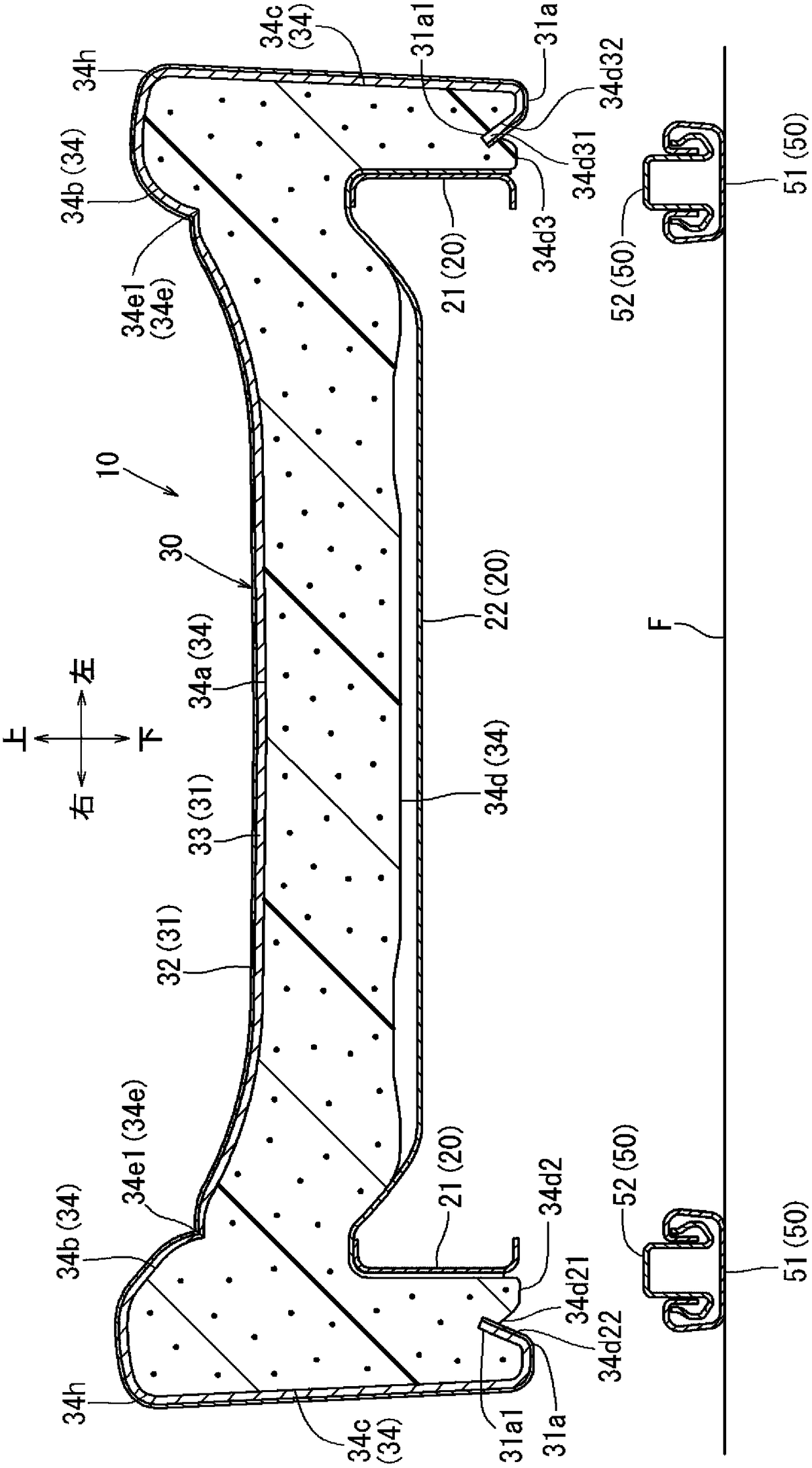

[0046] Figure 1 ~ Figure 3 One embodiment of the present invention is shown in FIG. This embodiment is a case of the seat constituent member 30 of the seat cushion 10 of an automobile seat. In each figure, the directions of the vehicle when the vehicle seat is mounted on the vehicle are indicated by arrows. In the following description, descriptions related to directions are based on the directions. Here, the seat component 30 corresponds to the "vehicle seat component" of the claim.

[0047] Generally, an automobile seat includes a seat cushion 10 as a seating portion, a seat back as a backrest, and a headrest for supporting the head. Such as figure 2 and image 3 As shown, the seat cushion 10 includes a cushion frame 20 constituting a skeleton and a seat constituent member 30 placed on the cushion frame 20 . In the cushion frame 20, the front parts of a pair of side frames 21 arranged to extend in the front-rear direction on the left and right sides of the seat cushi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap