Disintegration method of anterior shield of shield machine

A technology of shield machine and shield shell, which is applied in the direction of earth drilling, mining equipment, tunnels, etc. It can solve the problems of cumbersome operation, high restoration cost, and damage to the front shield center ring, etc., and achieve the effect of convenient operation and reduced restoration cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

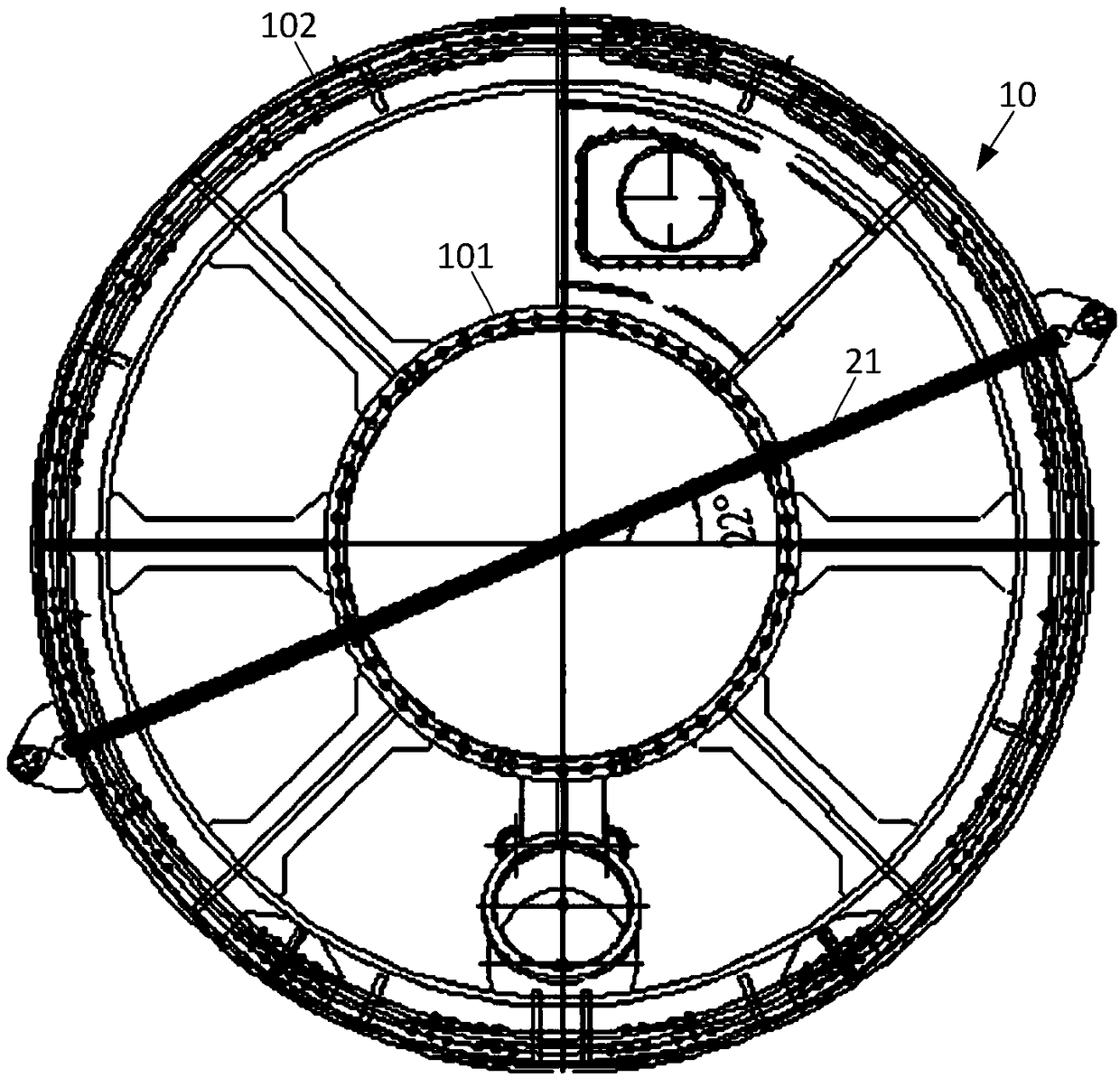

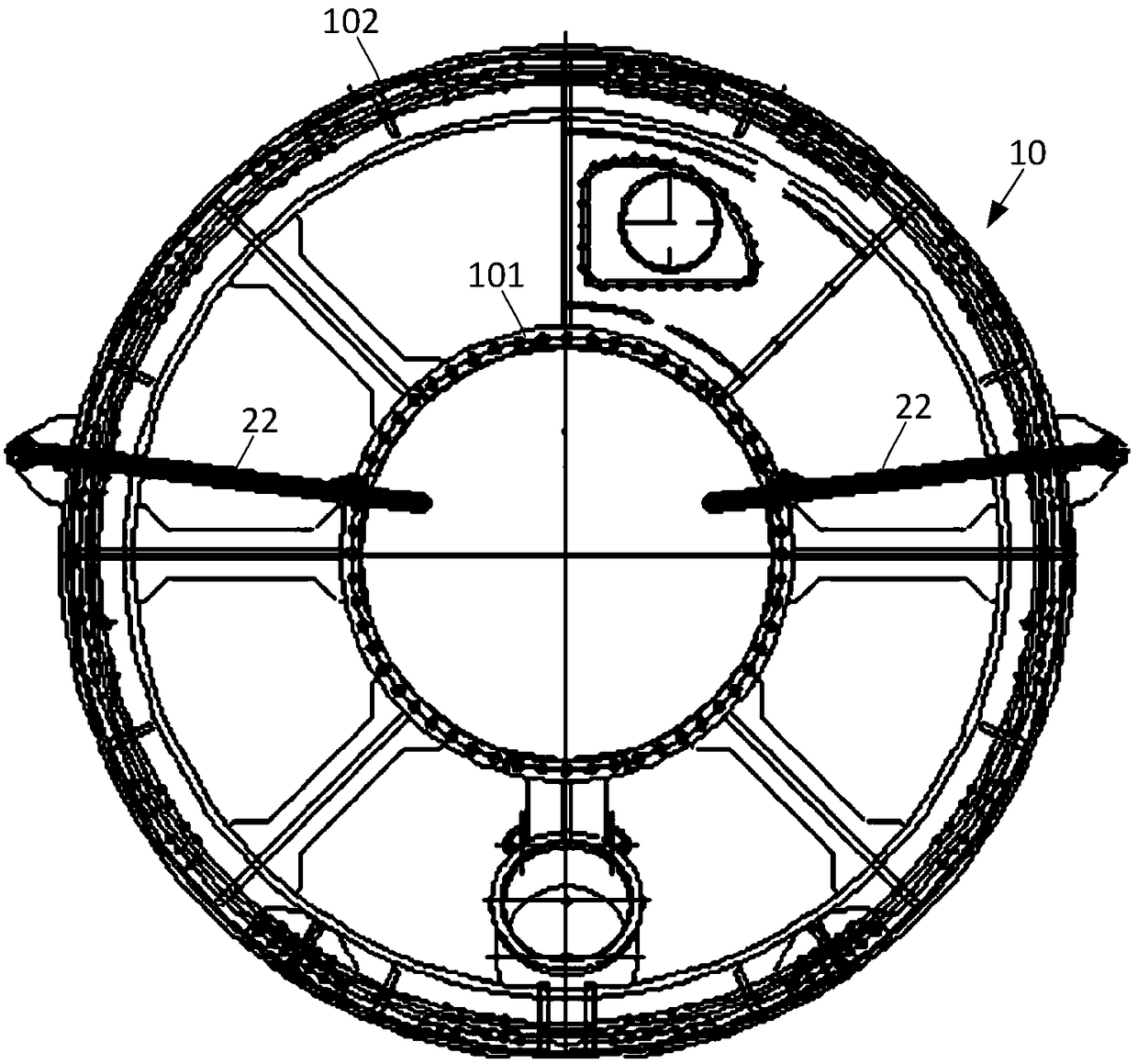

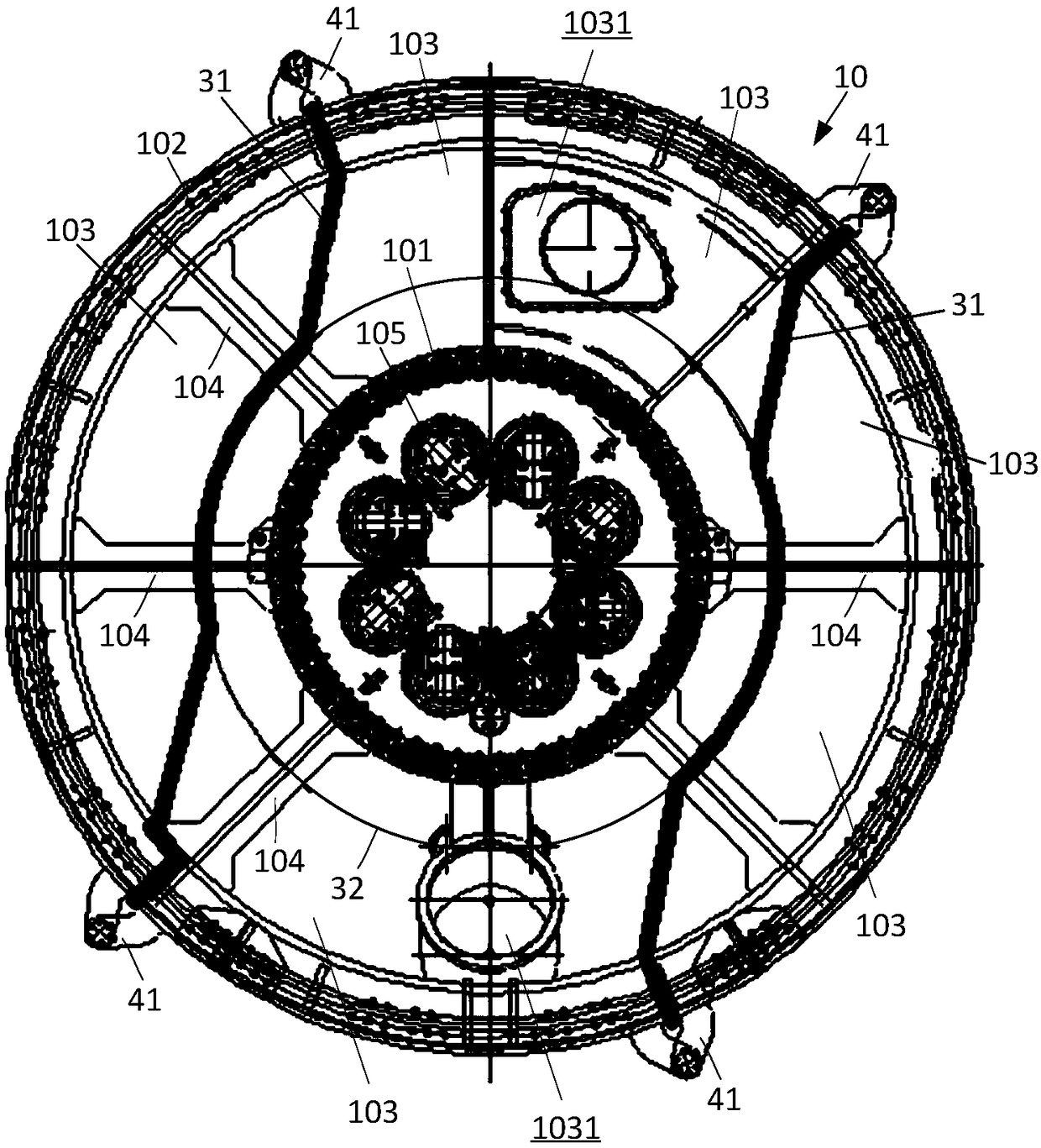

[0031] refer to image 3 , the present invention provides a method for dismantling the front shield of a shield machine, which is used to solve the existing problems of dividing the front shield in half or asymmetrical half-cut into two parts, and remove the main bearing to make the shield turn over times. Many problems, cumbersome operation and high recovery cost in the later stage. The disassembly method of the present invention divides the front shield into three parts: left, middle and right. The left and right sides are approximately symmetrical. The middle part completely retains the center ring and the opening on the soil tank panel, which avoids damage to the center ring and does not need to dismantle the main shield. The bearing avoids the turning operation of the shield body, can make the disassembly of the front shield more convenie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com