Automobile exhaust purifier capable of automatically removing coarse carbon particles

A technology for automatic cleaning of automobile exhaust, which is applied to exhaust devices, engine components, machines/engines, etc., can solve the problems of catalyst surface activity reduction, failure, blockage, etc., and achieve the effect of ensuring catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

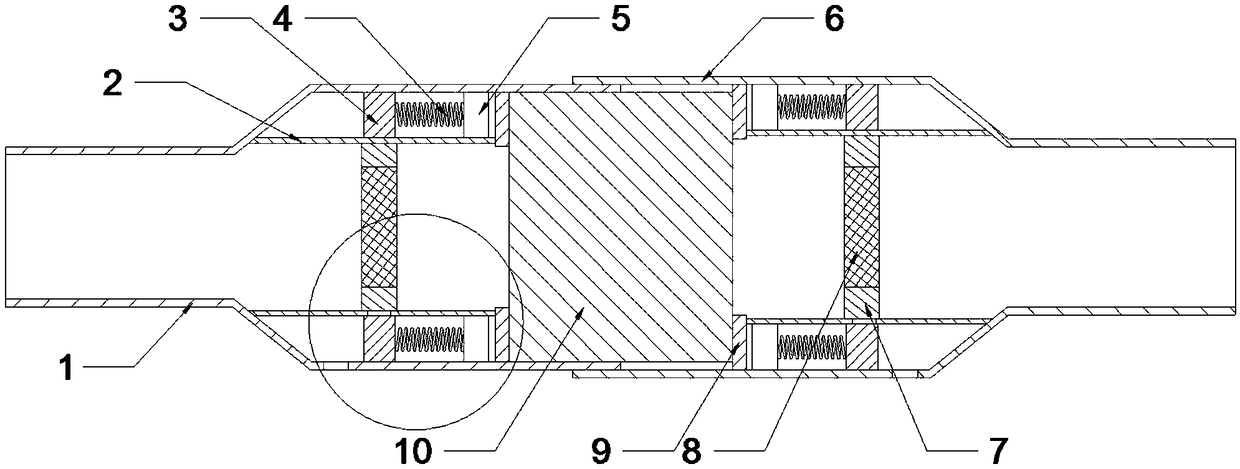

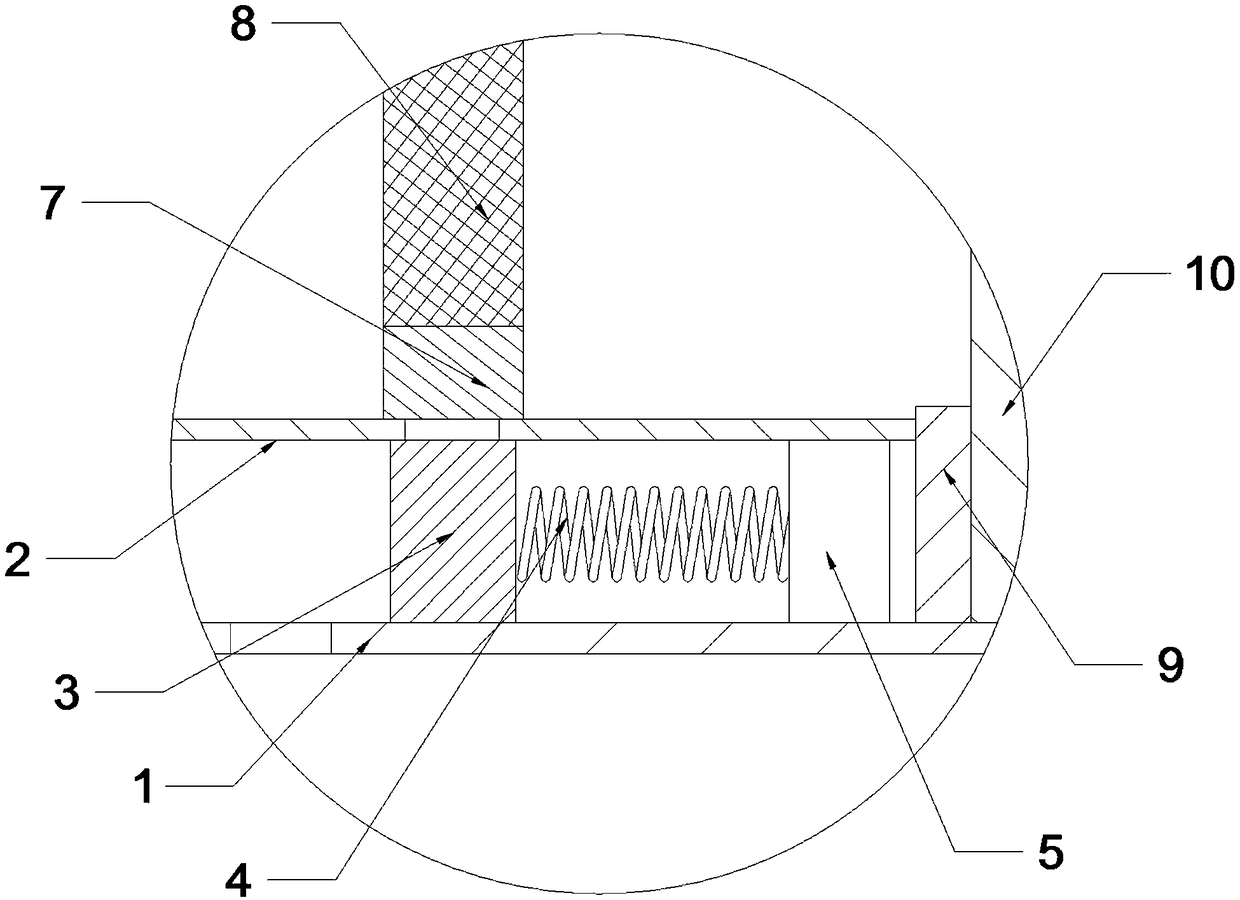

[0023] see Figure 1~2 , an automobile exhaust purifier for automatically cleaning coarse carbon particles, comprising a left outer cylinder 1, a right outer cylinder 6, a honeycomb carrier 10, the left outer cylinder 1 communicates with the inner wall of the right outer cylinder 6, and the connection mode is a detachable connection, The inner cylinder 2 is installed in the left outer cylinder 1 and the right outer cylinder 6, and a honeycomb carrier 10 is arranged between the two inner cylinders 2, and a catalyst layer is coated on the honeycomb holes of the honeycomb carrier 10. An electromagnet 5 and an outer magnet 3 are installed in the cavity of the right outer cylinder 6, an inner magnet 7 is installed in the inner cylinder 2, a coarse carbon filter screen 8 is installed on the inner magnet 7, and the positions of the inner magnet 7 and the outer magnet 3 correspond to each other .

[0024] In this example, the left outer cylinder 1 is separated from the right outer cy...

Embodiment 2

[0026] see Figure 1~2 , an automobile exhaust purifier for automatically cleaning coarse carbon particles, comprising a left outer cylinder 1, a right outer cylinder 6, a honeycomb carrier 10, the left outer cylinder 1 communicates with the inner wall of the right outer cylinder 6, and the connection mode is a detachable connection, The inner cylinder 2 is installed in the left outer cylinder 1 and the right outer cylinder 6, and a honeycomb carrier 10 is arranged between the two inner cylinders 2, and a catalyst layer is coated on the honeycomb holes of the honeycomb carrier 10. An electromagnet 5 and an outer magnet 3 are installed in the cavity of the right outer cylinder 6, an inner magnet 7 is installed in the inner cylinder 2, a coarse carbon filter screen 8 is installed on the inner magnet 7, and the positions of the inner magnet 7 and the outer magnet 3 correspond to each other .

[0027] The limit ring plate 9 is installed on the side of the inner cylinder 2 facing ...

Embodiment 3

[0030] see Figure 1~2 , an automobile exhaust purifier for automatically cleaning coarse carbon particles, comprising a left outer cylinder 1, a right outer cylinder 6, a honeycomb carrier 10, the left outer cylinder 1 communicates with the inner wall of the right outer cylinder 6, and the connection mode is a detachable connection, The inner cylinder 2 is installed in the left outer cylinder 1 and the right outer cylinder 6, and a honeycomb carrier 10 is arranged between the two inner cylinders 2, and a catalyst layer is coated on the honeycomb holes of the honeycomb carrier 10. An electromagnet 5 and an outer magnet 3 are installed in the cavity of the right outer cylinder 6, an inner magnet 7 is installed in the inner cylinder 2, a coarse carbon filter screen 8 is installed on the inner magnet 7, and the positions of the inner magnet 7 and the outer magnet 3 correspond to each other .

[0031]An opening is provided at the contact point between the inner magnet 7 and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com