Gaseous hydrocarbon self-heating conversion catalyst and preparation method thereof

A self-thermal conversion and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., to avoid the aggregation of active metal grains, ensure stability, increase Effect of Active Metal Dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

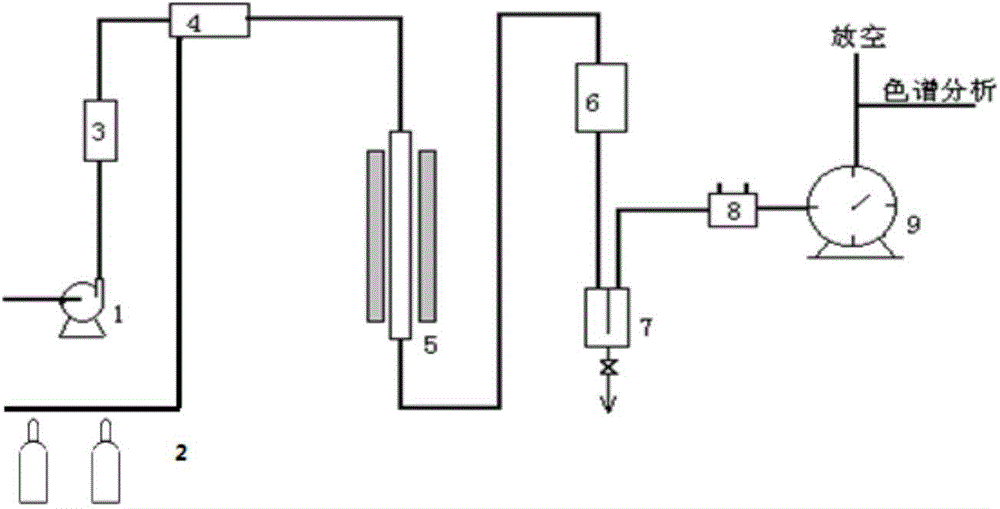

Method used

Image

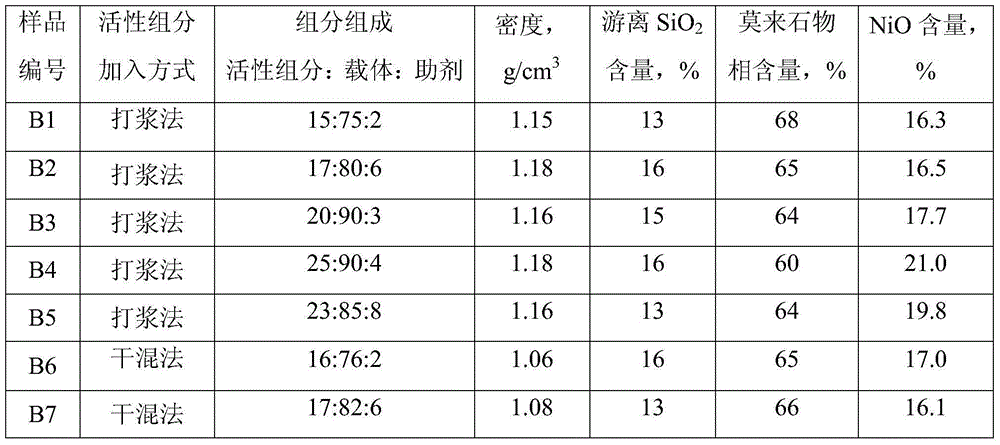

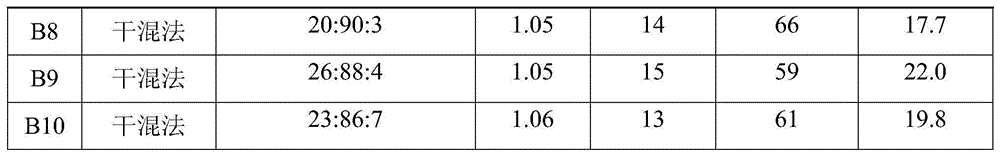

Examples

Embodiment 1

[0043] Take calcined kaolin (35.21% alumina, 55.31% silica, impurity ≤ 2%, the same below), add 15% NaOH solution by mass fraction, soak at 70°C for 4 hours, filter and wash until Na-free + It exists, dried at 120°C, and crushed to 280 mesh.

[0044]Weigh 58.4g of nickel nitrate and 12.8g of magnesium nitrate, dissolve them in 85g of water, add the aqueous solution to 82.5g of the above-mentioned alkali-modified kaolin, mix and make a slurry, put the slurry in an oven and dry at 120°C for 12 hours to obtain a semi-finished product A1.

Embodiment 2

[0046] Take calcined kaolin and add 15% NaOH solution with a mass fraction of 15% to keep soaking at 70°C for 4 hours, filter and wash until there is no Na + It exists, dried at 120°C, and crushed to 280 mesh.

[0047] Weigh 66.2g of nickel nitrate and 38.4g of magnesium nitrate, dissolve them in 90g of water, add the aqueous solution to 88g of the above-mentioned alkali-modified kaolin, mix and make a slurry, put the slurry in an oven and dry at 120°C for 12 hours to obtain a semi-finished product A2.

Embodiment 3

[0049] Take calcined kaolin, add mass fraction 17% NaOH solution, keep soaking at 75°C for 4 hours, filter and wash until there is no Na + It exists, dried at 120°C, and crushed to 280 mesh.

[0050] Weigh 77.8g of nickel nitrate and 19.2g of magnesium nitrate, dissolve them in 100g of water, add the aqueous solution to 95g of the above-mentioned alkali-modified kaolin, mix and make a slurry, put the slurry in an oven and dry at 120°C for 12 hours to obtain a semi-finished product A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com