A pilot-operated hydraulic control stop valve

A shut-off valve, pilot-operated technology, applied in the field of shut-off valves, can solve the problems of low working pressure, reduce the life of the shut-off valve, and the flow rate is not particularly large, and achieve the effects of small closing impact, compact overall size and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

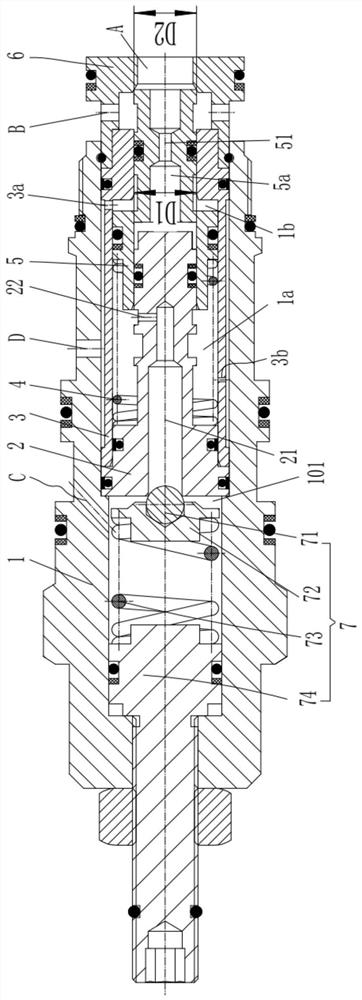

[0011] The present invention will be further described in detail below with reference to the accompanying drawings embodiments.

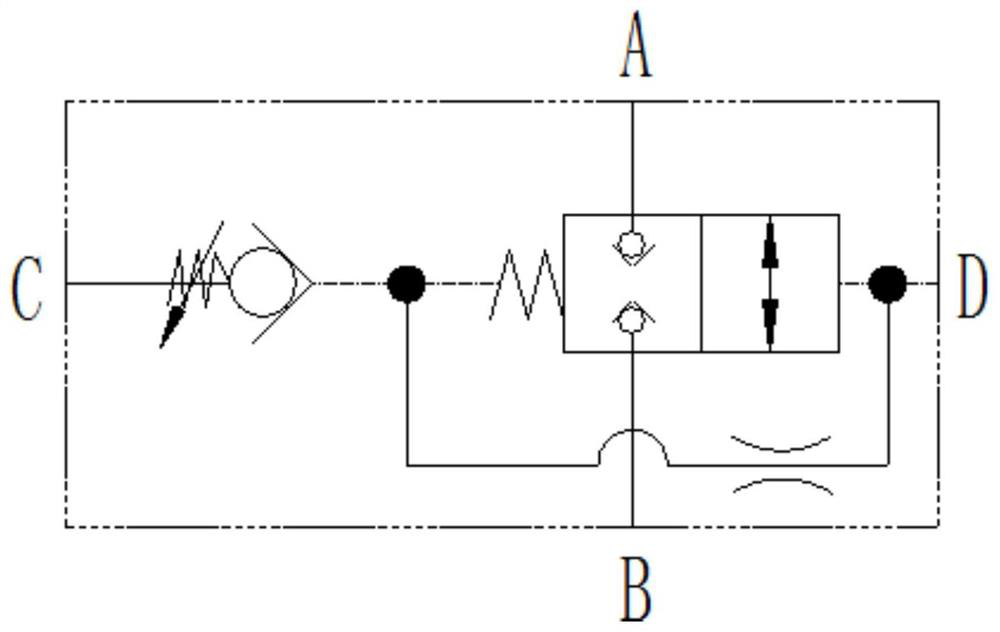

[0012] Such as Figure 1 ~ 2 As shown, it is a preferred embodiment of the present invention.

[0013] A pilot-controlled shut-off valve, including

[0014] The valve body 1 having axial through holes 101, the sidewall of the valve body 1 opens the third port C and the fourth oil port D in communication with the axial through hole 101.

[0015] The valve seat 6 fixed to the right end of the axial through hole 101 is attached to the first port A in communication with the axial through hole 101 on the right end surface of the valve seat 6, and the side wall of the valve seat 6 opens and axial through holes. The second oil port B is connected 101.

[0016] The first liner 2, the second liner 3, and the spool 5, the first liner 2 and the second liner 3 are fixed to the axial through hole 101, and the spool 5 is provided in the second liner 3 and can be left....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com