Hardness measurement device and hardness measurement method

A technology of measuring device and measuring method, which is applied in the direction of measuring device, testing material hardness, strength characteristics, etc., can solve the problems of low testing efficiency and low precision, and achieve the effect of accurate hardness value and improved precision and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

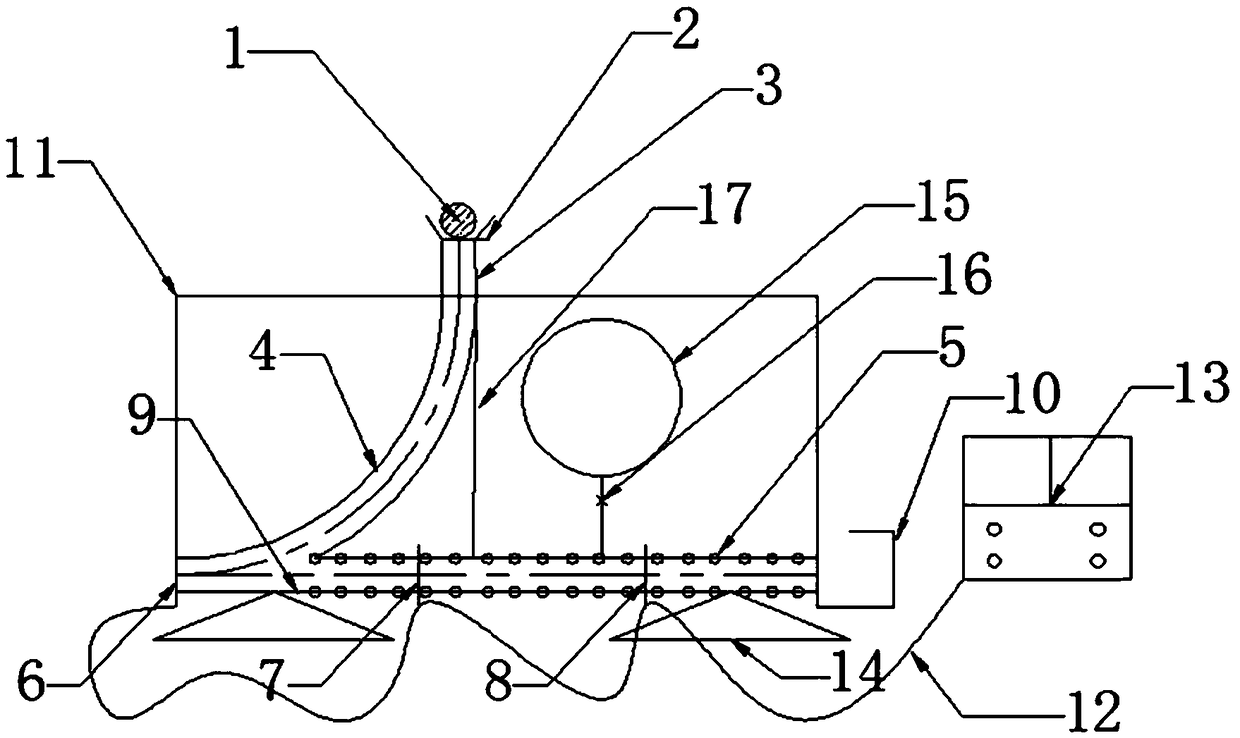

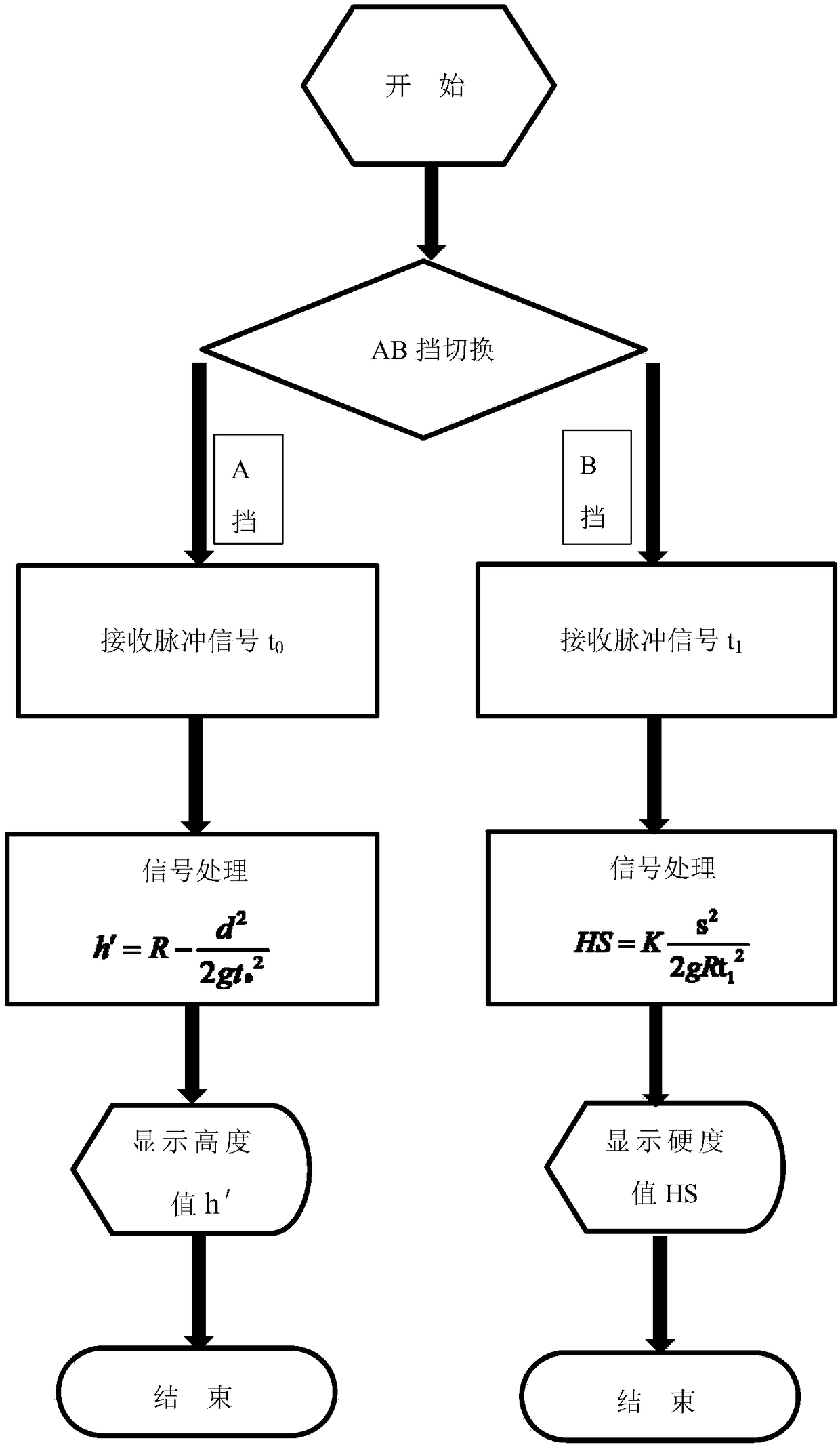

[0031] to combine figure 1 According to one aspect of the present invention, a hardness measuring device is provided, comprising: a test ball 1, a first channel for realizing the test ball sliding down, and a second channel 9 for realizing the horizontal uniform velocity linear motion of the test ball, The first passage includes a 1 / 4 circular arc passage 4 with a vertical inlet and a horizontal outlet, and the entrance of the 1 / 4 circular arc passage 4 is higher than the outlet of the 1 / 4 circular arc passage 4, The outlet of the 1 / 4 circular arc channel 4 intersects with the inlet of the second channel 9 and forms a connected connecting portion, and the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com