Quick evaluation method of sensory quality of oral tobacco base material in bags

A sensory quality and evaluation method technology, applied in measurement devices, analytical materials, instruments, etc., can solve the problems of low sensory quality work efficiency, long sample evaluation interval, and scattered judgment result data, etc. To achieve the effect of improving the judgment speed and efficiency, avoiding the difference of components, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

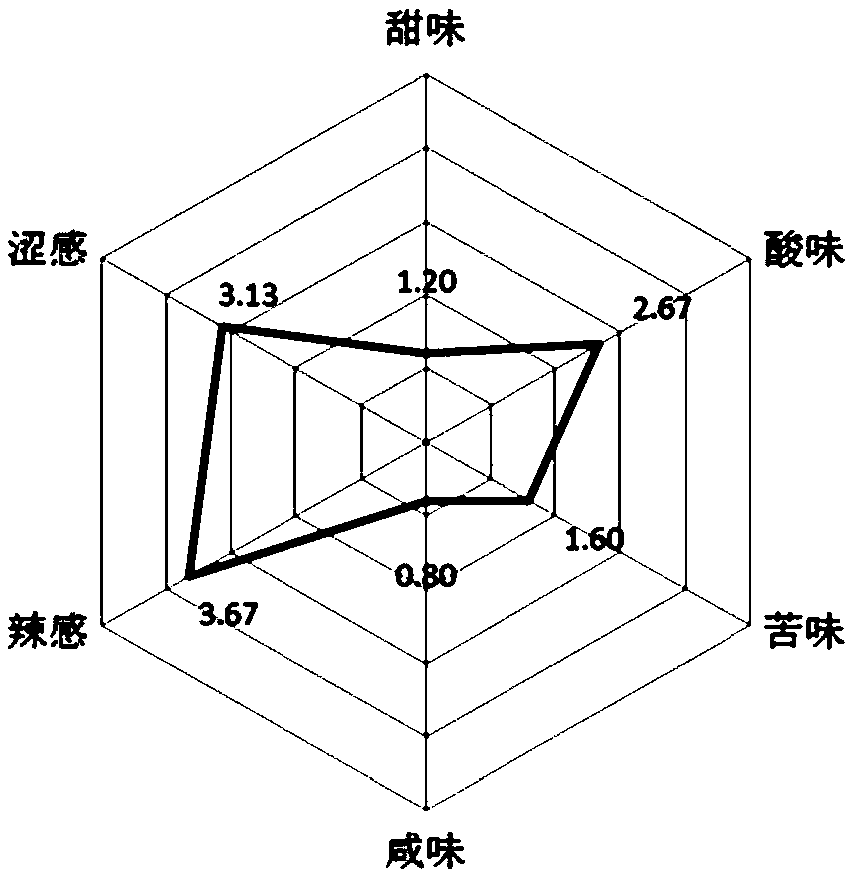

[0049] Taking the bagged snus sample (sample number: HL01#) made from air-cured tobacco produced in Yunxi, Sichuan as an example, the rapid evaluation method for the sensory quality of the bagged snus base material includes the following steps:

[0050] 1) Take 15 bags of snus samples in bags (0.3g per bag), immerse them in 150mL of pure water with a constant temperature of 35°C, extract for 1min, take out the snus samples in each bag, and obtain the bagged snus samples. Material leachate;

[0051] 2) Immediately divide the bagged snus base material leach solution obtained in step 1) into 15 tasting cups, and distribute it to 15 members of the panel of judges for tasting, 5mL bagged snus base material leachate in each tasting cup ;Each member immediately and independently judges the sweetness, sourness, bitterness, saltiness, hotness, astringency, miscellaneous taste and aftertaste of the bagged snus base material leachate; In the evaluation table (see Table 2), score sweetne...

Embodiment 2

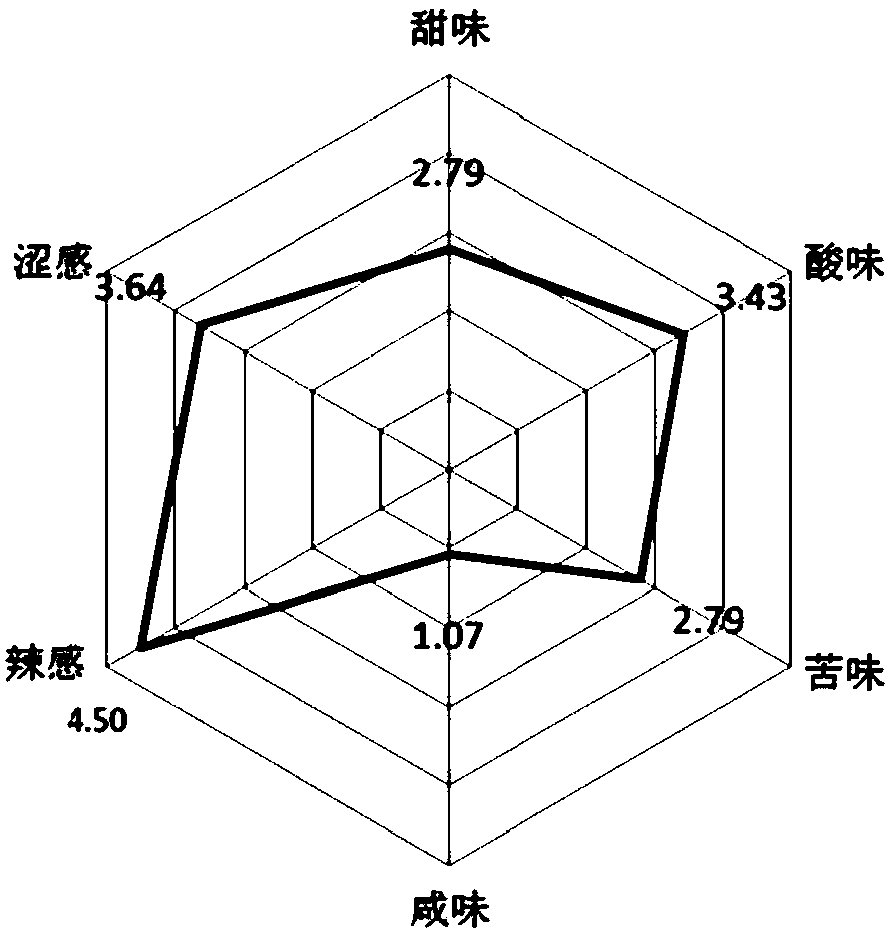

[0062] Taking the bagged snus sample (sample number: HL02#) made from air-cured tobacco produced in the Hefeng area of Sichuan as an example, the rapid evaluation method for the sensory quality of the bagged snus base material is compared with the evaluation method in Example 1. The only difference is: Step 1) Take 15 bags of snus samples in bags (0.3g per bag), immerse them in 150mL of pure water with a constant temperature of 30°C, extract for 30s, take out the snus samples in each bag, and obtain the bag Fill the leaching solution of the mouth-containing tobacco base material; the rest of the steps are exactly the same.

[0063] According to the sensory quality evaluation results of pouched snus base material, a radar chart is drawn, see figure 2 , and express the sensory quality evaluation results of the snus base material with the sample number HL02# in words: slightly sweet, slightly spicy, slightly bitter aftertaste, astringent on the tongue, and herbal taste.

Embodiment 3

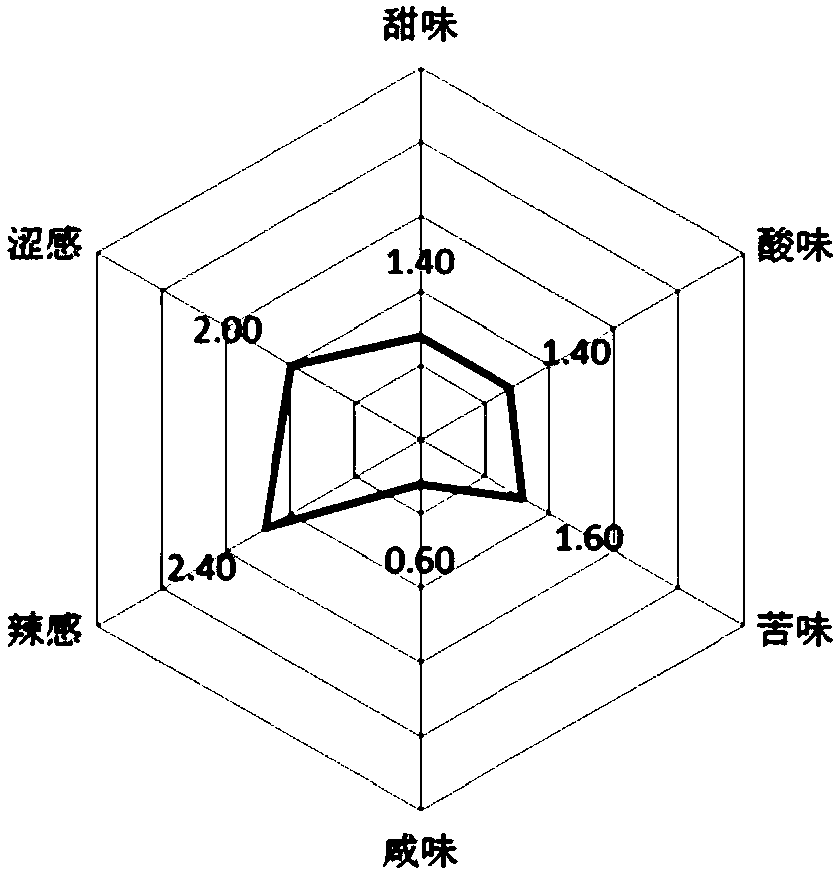

[0065] Taking the bagged snus sample (sample number: HL03#) made from air-cured tobacco produced in Xianfeng, Sichuan as an example, the difference between the rapid evaluation method for the sensory quality of the bagged snus base material and the evaluation method in Example 1 Only in: Step 1) Take 15 bags of snus samples in bags (0.3g per bag), immerse them in 150mL of pure water with a constant temperature of 40°C, extract for 45s, take out the snus samples in bags, and obtain the bagged snus samples. snus base material extract; the rest of the steps are exactly the same.

[0066] According to the sensory quality evaluation results of pouched snus base material, a radar chart is drawn, see image 3 , and express the sensory quality evaluation results of the snus base material with the sample number HL03# in words: slightly bitter, sweet and refreshing aftertaste, herbal aroma, clean, moist tobacco smell, and comfortable aftertaste.

[0067] In addition, the bagged snus sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com