Polyethylene-based resin composition for foamable laminated body, foamable laminated body, method for producing same, foam-processed paper, and heat insulation container

A polyethylene-based resin and a technology for a manufacturing method, which are applied in the field of polyethylene-based resin compositions for foamable laminates, can solve the problems of poor microwave applicability, damage to appearance, and poor appearance, and achieve the effect of excellent microwave applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

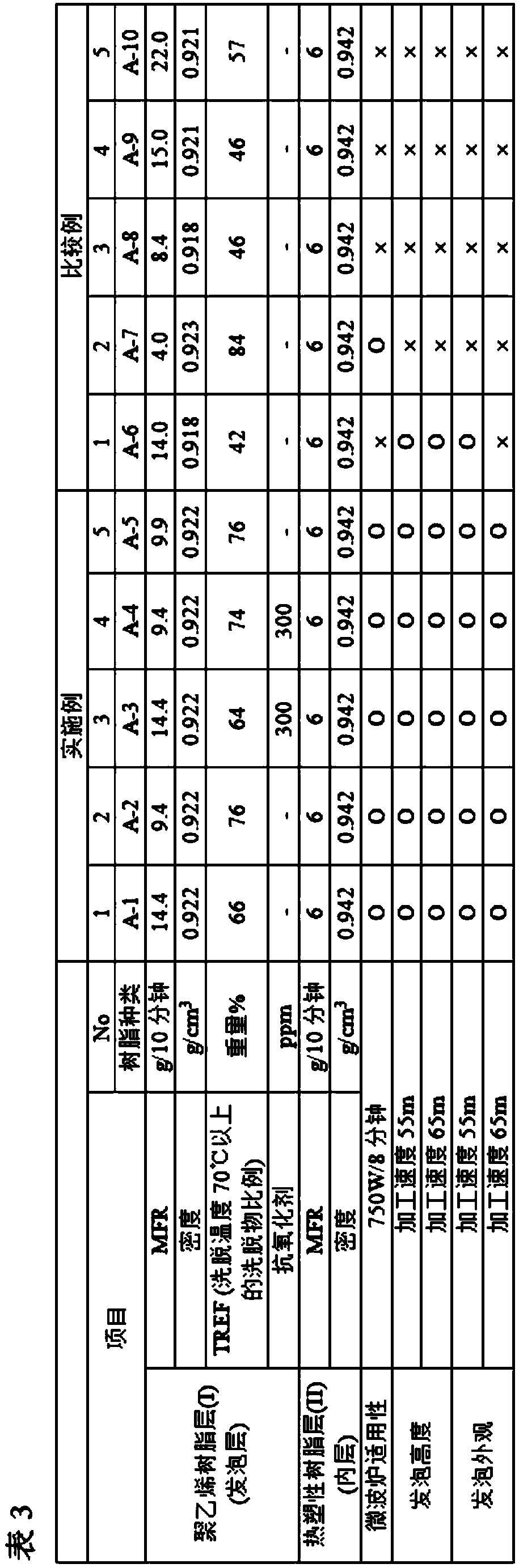

[0208] As the resin used for the polyethylene-based resin layer (thermoplastic resin layer) (II), an MFR of 6 g / 10 minutes and a density of 0.942 g / cm were used 3 Medium density polyethylene with a melting temperature of 130°C.

[0209] The unit weight is 320g / m 2 And the paper substrate with a moisture content of 7% carries out corona treatment (30W.min / m 2 ). Using a 90 mmφ extruder (manufactured by Sumitomo Heavy Industries Modern, Ltd.) and an extrusion laminator with an air gap of 110 mm and a die effective width of 560 mm, polyethylene was formed in a thickness of 40 μm at a resin temperature of 320° C. and Extrusion lamination processing was performed thereon at a processing speed of 50 m / min, whereby a laminate of the polyethylene-based resin layer (thermoplastic resin layer) (II) and the paper base material was obtained.

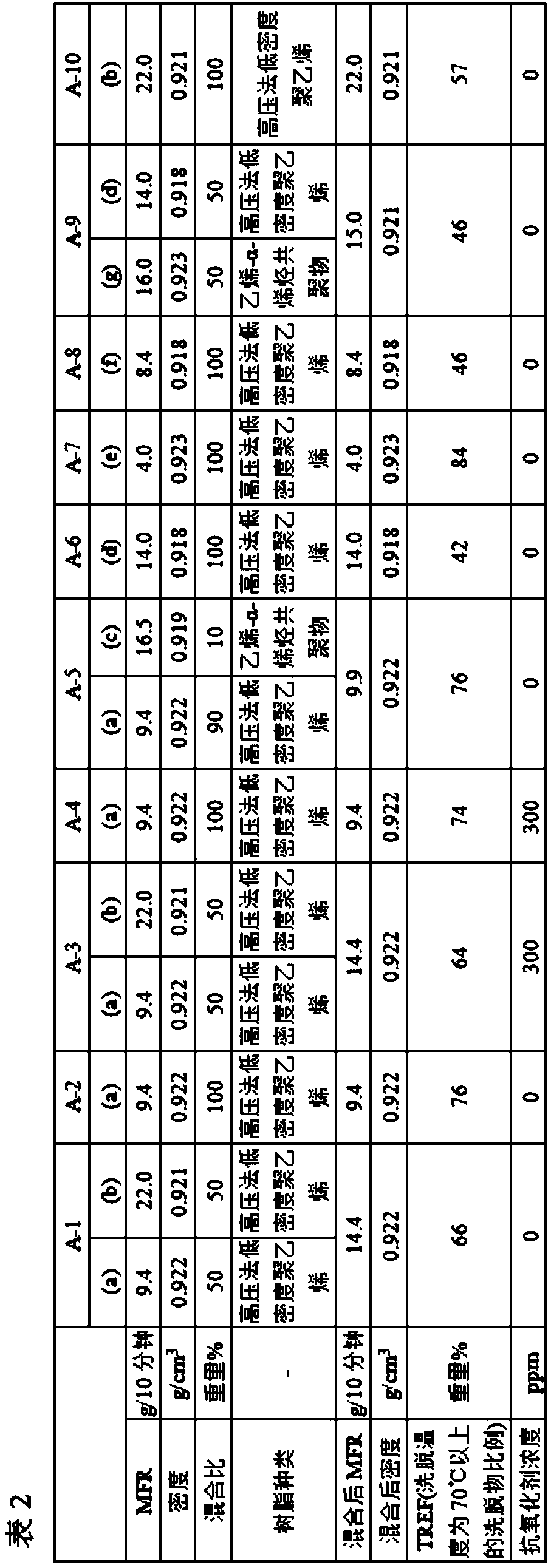

[0210] Next, corona treatment (30W·min / m 2 ). The polyethylene-based resin (A-1) shown in the following Table 2 was supplied to a film having ...

Embodiment 2

[0213] A foamable laminate was obtained in the same manner as in Example 1 except that the polyethylene resin (A-2) shown in Table 2 below was used as the resin for the polyethylene-based resin layer (I).

[0214] Table 3 shows the evaluation results of the obtained foamable laminate. Good results for foam appearance and foam height were obtained both at a processing speed of 55 m / min and at a processing speed of 65 m / min. In addition, in terms of microwave oven applicability, no abnormality was observed in the foamed layer.

Embodiment 3

[0216] A foamable laminate was obtained in the same manner as in Example 1 except that the polyethylene resin (A-3) shown in Table 2 below was used as the resin for the polyethylene-based resin layer (I).

[0217] Table 3 shows the evaluation results of the obtained foamable laminate. Good results for foam appearance and foam height were obtained both at a processing speed of 55 m / min and at a processing speed of 65 m / min. In addition, in terms of microwave oven applicability, no abnormality was observed in the foamed layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com