Machining anti-static worktable

A mechanical processing and anti-static technology, applied in the direction of workbench, static electricity, electrotherapy, etc., can solve the problems that the workbench cannot meet the use requirements, the push-pull search is inconvenient to use, and the desktop space is occupied. The effect of manpower and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

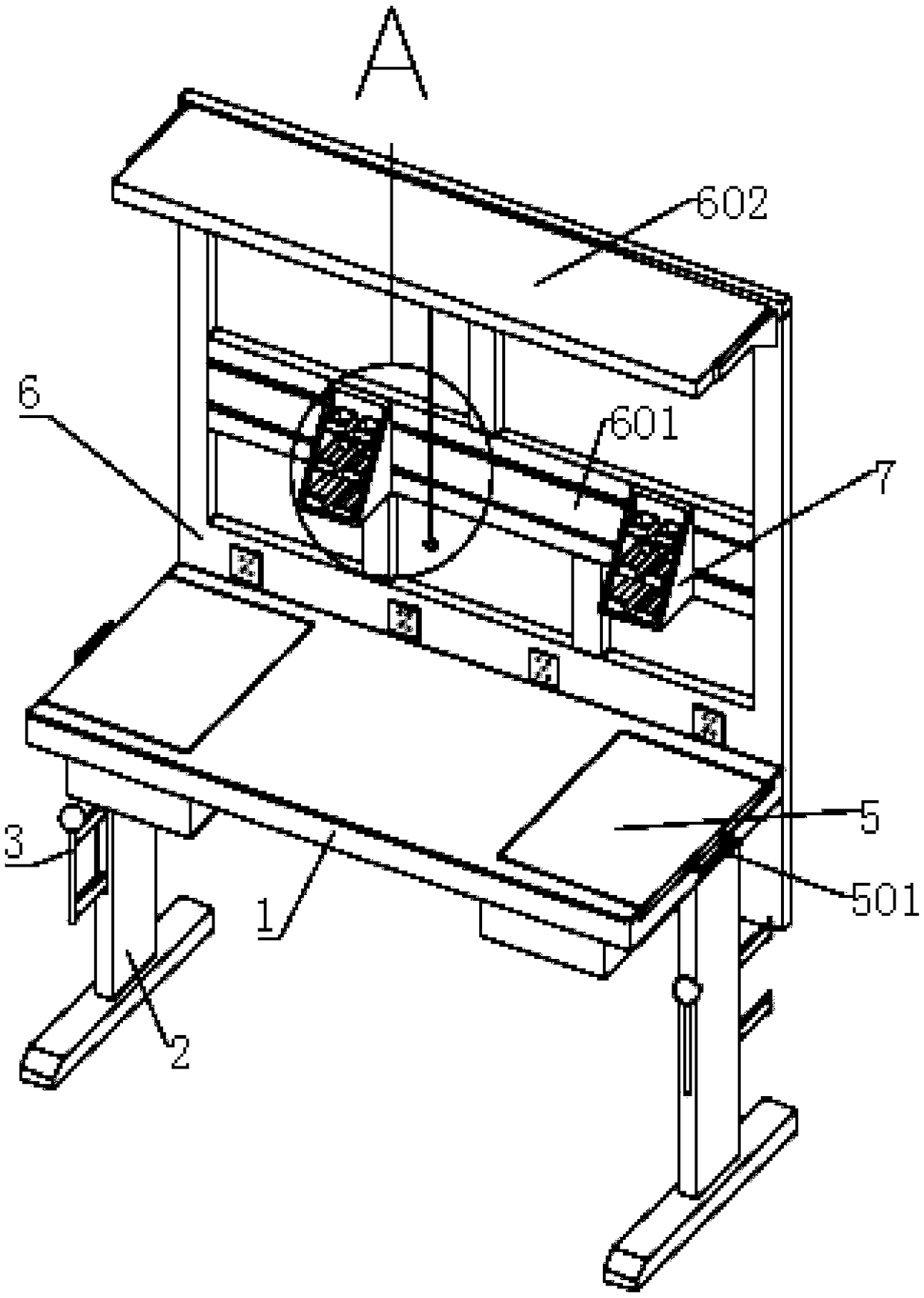

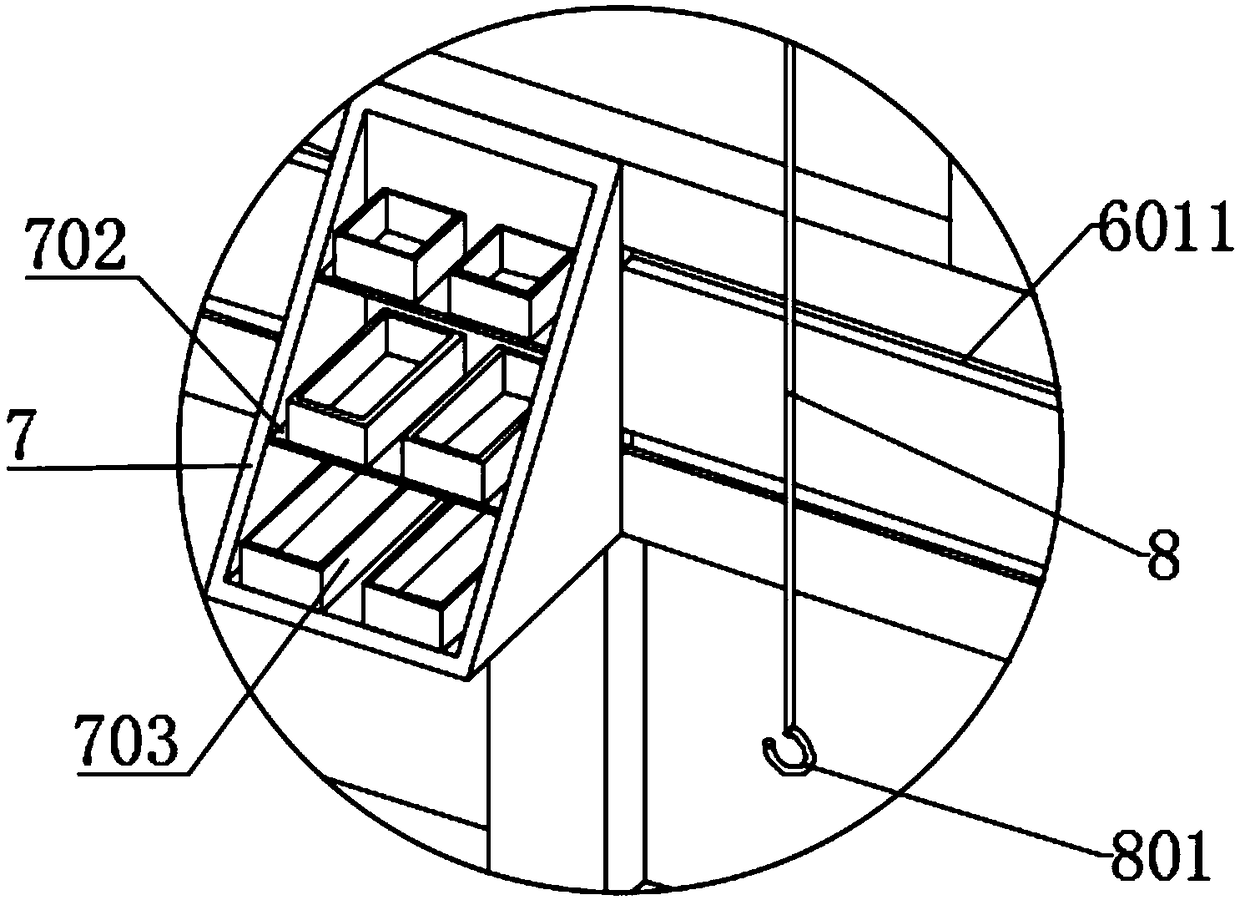

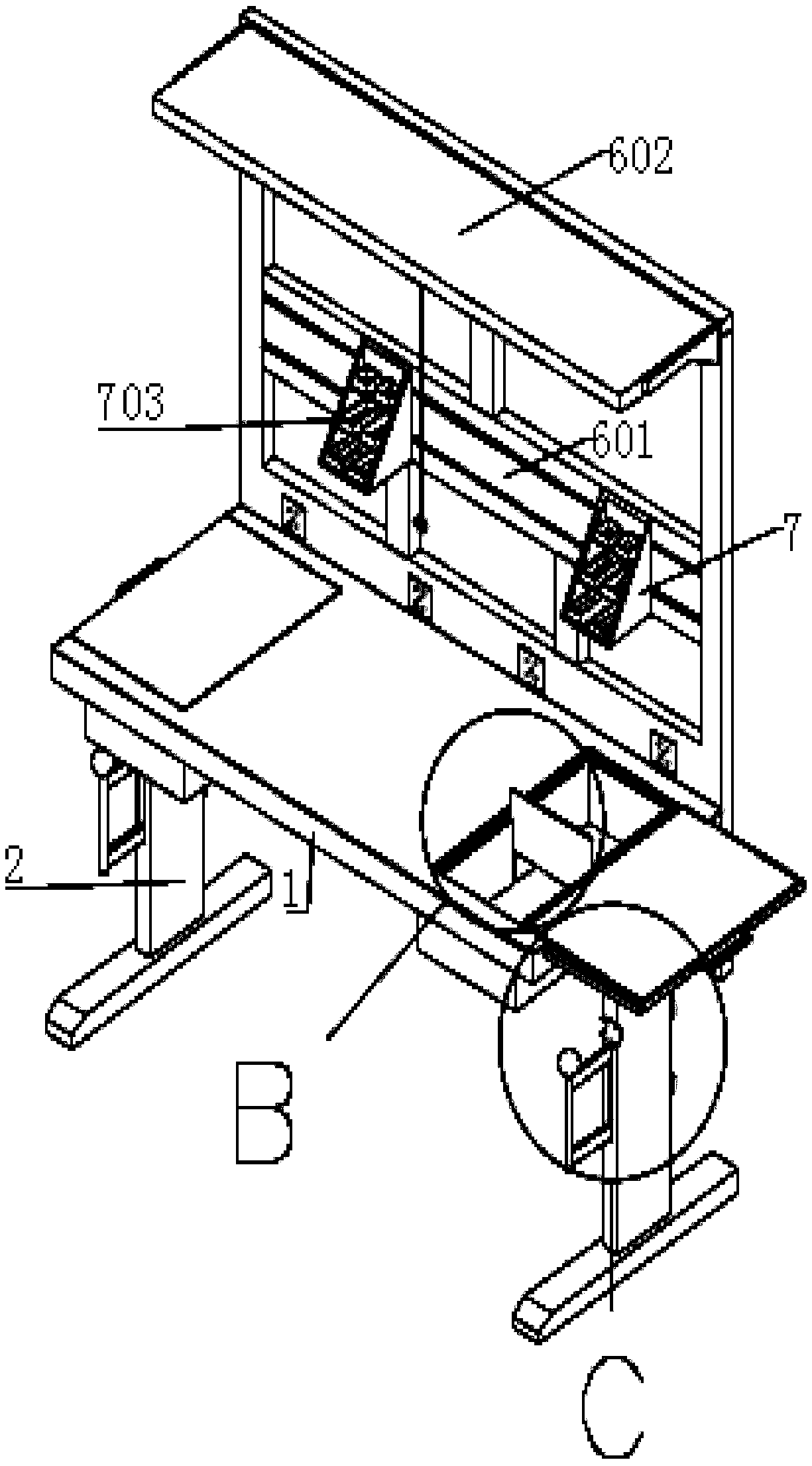

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035]The invention provides a mechanically processed anti-static workbench, which includes a workbench 1, a placement groove 101, a slot 102, a vertical chute 103, a sliding partition 104, support legs 2, through holes 201, a card groove 202, a static discharge Putting clubs 3, sliding connecting plate 301, anti-static table mat 4, convex sliding cover plate 5, push-pull handle 501, rear plate 502, rear baffle plate 6, middle horizontal plate 601, L-shaped chute 6011, top plate 602 , LED lamp 6021, hook 6022, triangular conical tool box 7, L-shaped slider 701, crosspiece 702, tool box 703, sling 8 and hook 801; The raised placement groove 101, and the upper end side of the placement groove 101 is provided with a slot 102, the convex sliding cover plate 5 is inserted into the slot 102 by its two ends and installed on the top of the placement groove 101, and the convex sliding cover The rear end of the board 5 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com