A method for manufacturing ceramic tiles with beautiful seams

A manufacturing method and ceramic tile technology, which is applied in the direction of manufacturing tools, ceramic molding cores, ceramic molding machines, etc., can solve the problems of slowing down the speed of user occupancy, prolonging the decoration time, and heavy workload, so as to facilitate laying and speed up occupancy , to avoid the effect of heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for manufacturing ceramic tiles with beautiful joints, specifically comprising the following steps:

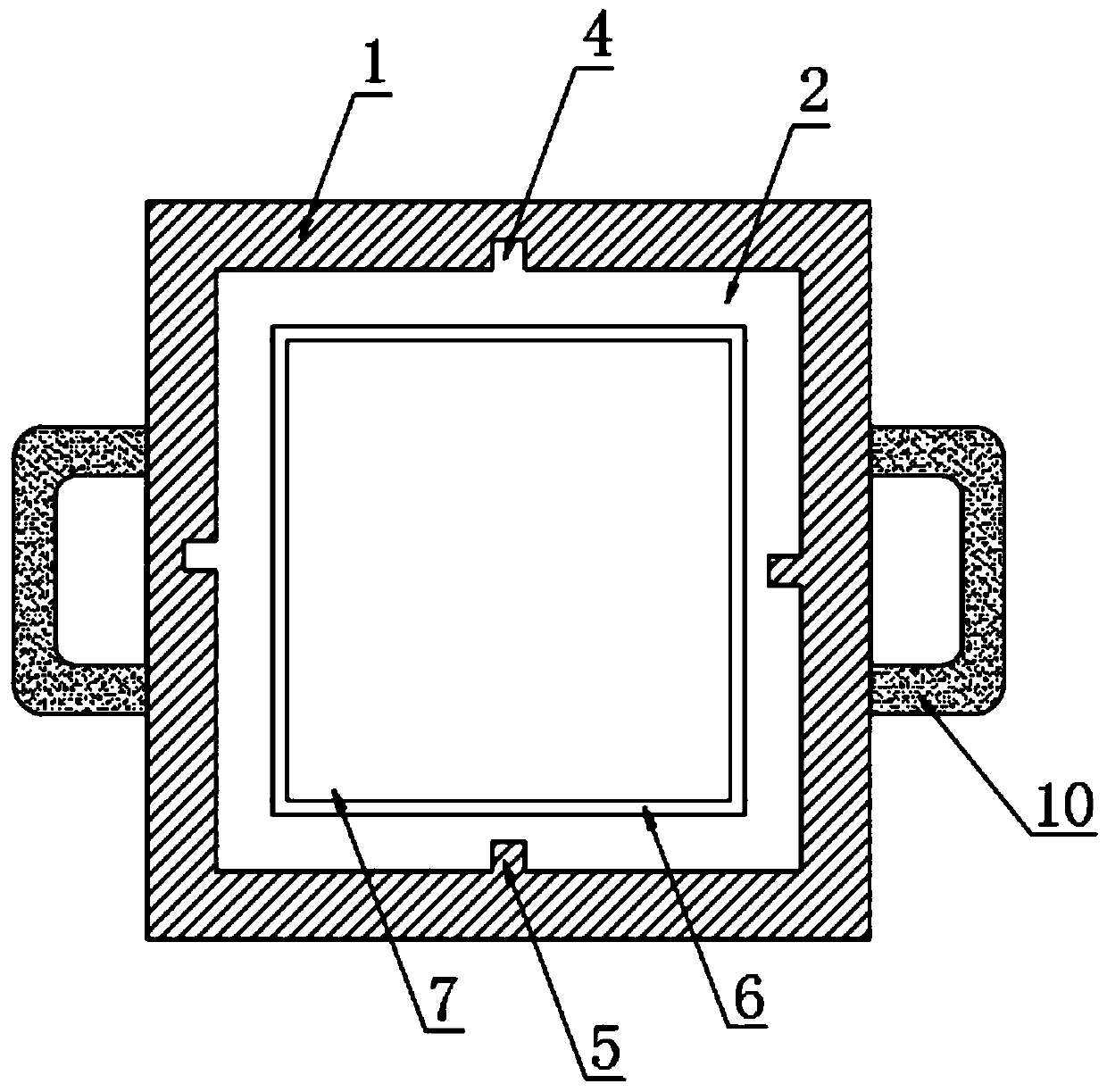

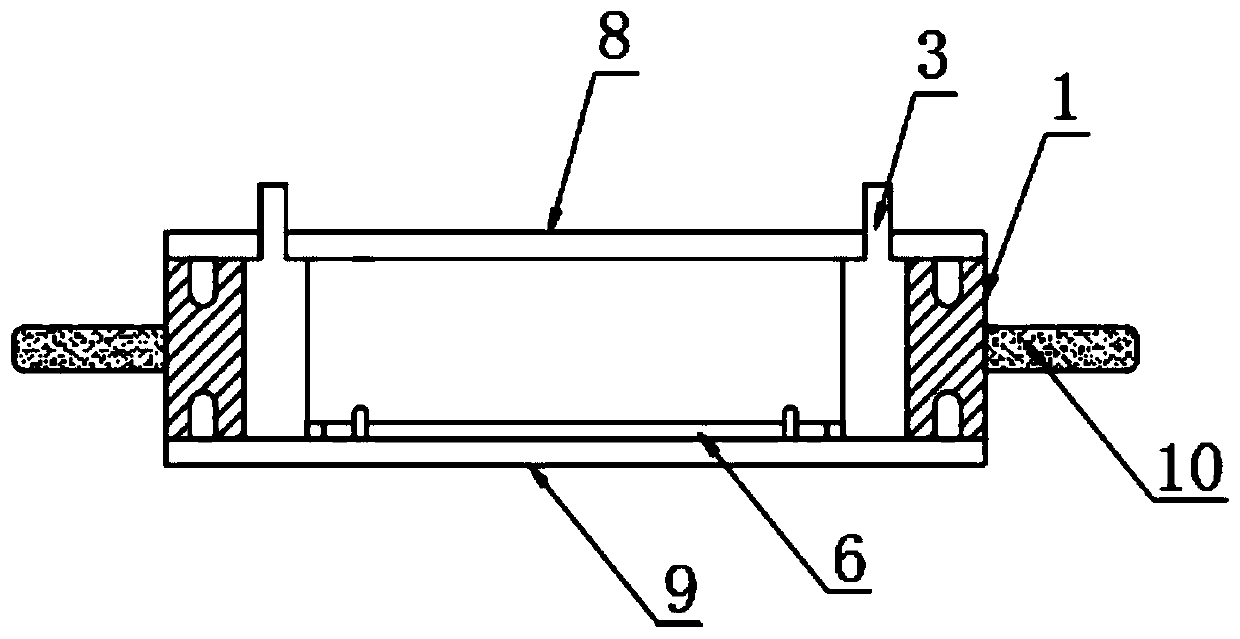

[0030] Step 1: prepare a forming mold, the forming mold includes an outer mold 1, an inner mold 2 is arranged on the inner side of the outer mold 1, a connecting column 3 is arranged on the top of the inner mold 2, and the top and one side of the inner mold 2 are arranged A bump 4 is provided, a groove 5 is provided at the bottom and the other side of the inner mold 2, a limit bar 6 is provided at the inner bottom end of the inner mold 2, a molding groove 7 is arranged at the inner side of the inner mold 2, and the inner mold 2 is provided with a molding groove 7. The top of the outer mold 1 is provided with a top cover 8 and the bottom is provided with a bottom cover 9, and both sides of the outer mold 1 are fixed with handles 10;

[0031] Step 2: Pour the ceramic blank into the forming tank 7 described in step 1, and flatten and compact the ceramic blank in t...

Embodiment 2

[0042] A method for manufacturing ceramic tiles with beautiful joints, specifically comprising the following steps:

[0043] Step 1: prepare a forming mold, the forming mold includes an outer mold 1, an inner mold 2 is arranged on the inner side of the outer mold 1, a connecting column 3 is arranged on the top of the inner mold 2, and the top and one side of the inner mold 2 are arranged A bump 4 is provided, a groove 5 is provided at the bottom and the other side of the inner mold 2, a limit bar 6 is provided at the inner bottom end of the inner mold 2, a molding groove 7 is arranged at the inner side of the inner mold 2, and the inner mold 2 is provided with a molding groove 7. The top of the outer mold 1 is provided with a top cover 8 and the bottom is provided with a bottom cover 9, and both sides of the outer mold 1 are fixed with handles 10;

[0044] Step 2: Pour the ceramic blank into the forming tank 7 described in step 1, and flatten and compact the ceramic blank in t...

Embodiment 3

[0055] A method for manufacturing ceramic tiles with beautiful joints, specifically comprising the following steps:

[0056] Step 1: prepare a forming mold, the forming mold includes an outer mold 1, an inner mold 2 is arranged on the inner side of the outer mold 1, a connecting column 3 is arranged on the top of the inner mold 2, and the top and one side of the inner mold 2 are arranged A bump 4 is provided, a groove 5 is provided at the bottom and the other side of the inner mold 2, a limit bar 6 is provided at the inner bottom end of the inner mold 2, a molding groove 7 is arranged at the inner side of the inner mold 2, and the inner mold 2 is provided with a molding groove 7. The top of the outer mold 1 is provided with a top cover 8 and the bottom is provided with a bottom cover 9, and both sides of the outer mold 1 are fixed with handles 10;

[0057] Step 2: Pour the ceramic blank into the forming tank 7 described in step 1, and flatten and compact the ceramic blank in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com