Nano-film heating plate and automatic production line process thereof

An automated production line and nano-film technology, which is applied to the surface coating liquid device, coating, sorting, etc., can solve the problems that cannot be widely promoted, the manufacturing process is complicated, and the cost is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of this application is as follows:

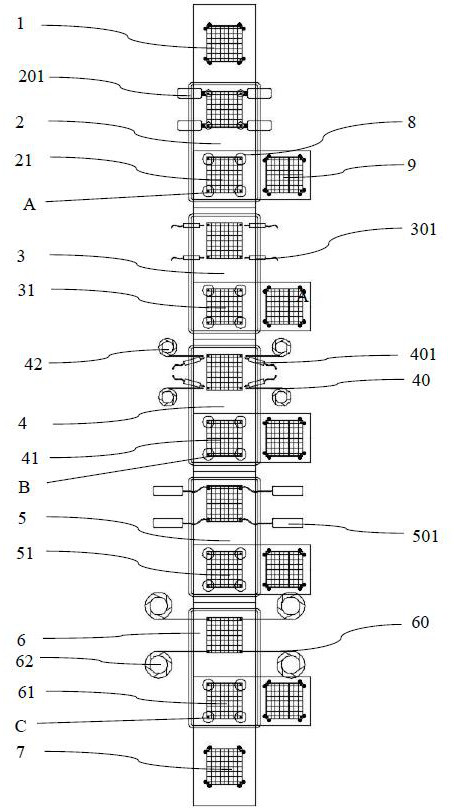

[0025] Such as figure 1 The nano-film heating plate and its automated production line process, the automated production line includes a feeding device 1, a laser glue removal device 2, a solder paste spraying device 3, a laser welding device 4, an AB glue filling device 5, and a rubber cap assembly device 6 , Five sets of visual inspection devices and a discharge device 7, each device uses an independent machine to work in a series assembly line transfer mode. The five sets of visual detection devices include surface CCD visual detection device 21, solder paste CCD visual detection device 31, welding CCD visual detection device 41, glue filling CCD visual detection device 51, assembly CCD visual detection device 61, each set of visual detection The devices are equipped with a defective product storage area 9 .

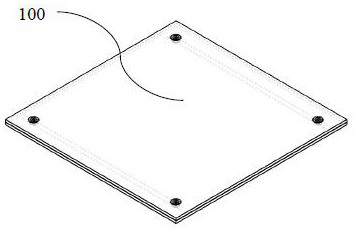

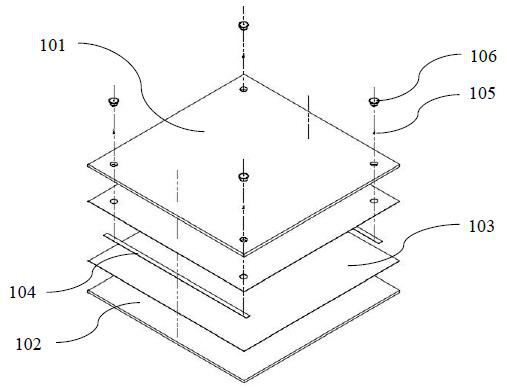

[0026] as shown in the picture figure 2 and image 3 As mentioned above, the shown nano-film h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com