Energy-saving section steel strapping device

A strapping device, energy-saving technology, applied in the direction of strapping objects, packaging/bundling items, strapping machine parts, etc., can solve the problems of increasing cost and use costs, increasing pollution control costs and burdens, etc., to achieve fast strapping and palletizing Neat and beautiful, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment provides an energy-saving section steel binding device using a quadrilateral clamp,

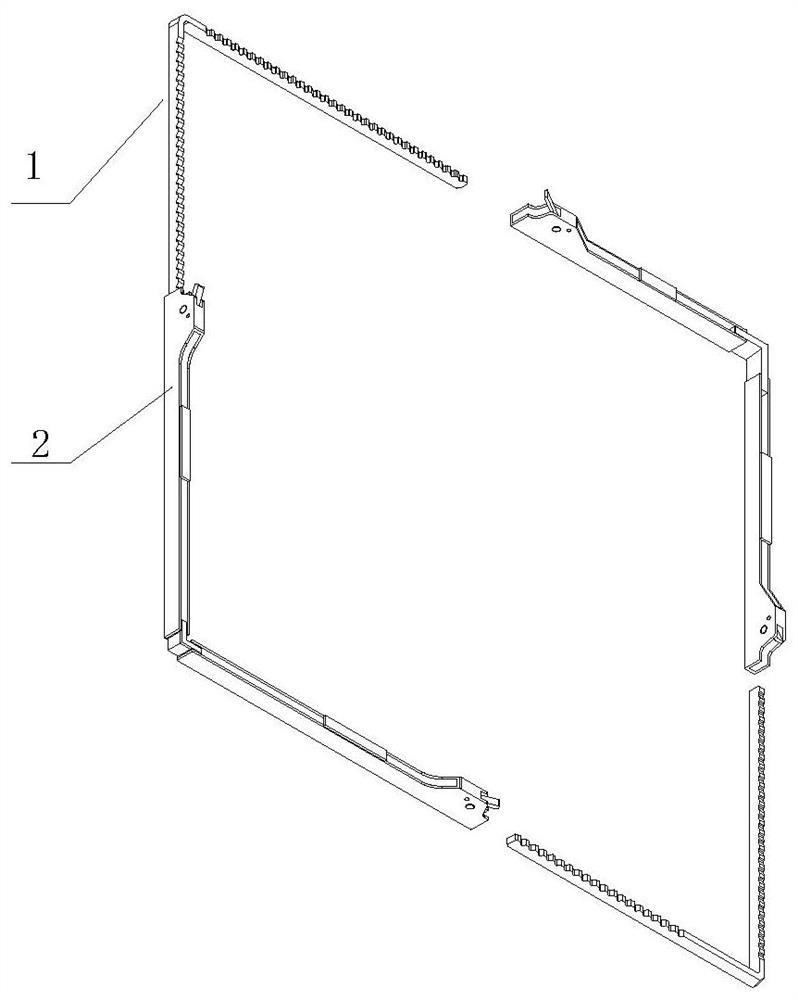

[0022] See figure 1 -(1), the quadrilateral clamp is composed of two L-shaped racks 1 and two L-shaped gear sleeves 2 staggeredly inserted. The racks and the gear sleeves are set in a ratchet structure, so they have the function of tightening and preventing loosening;

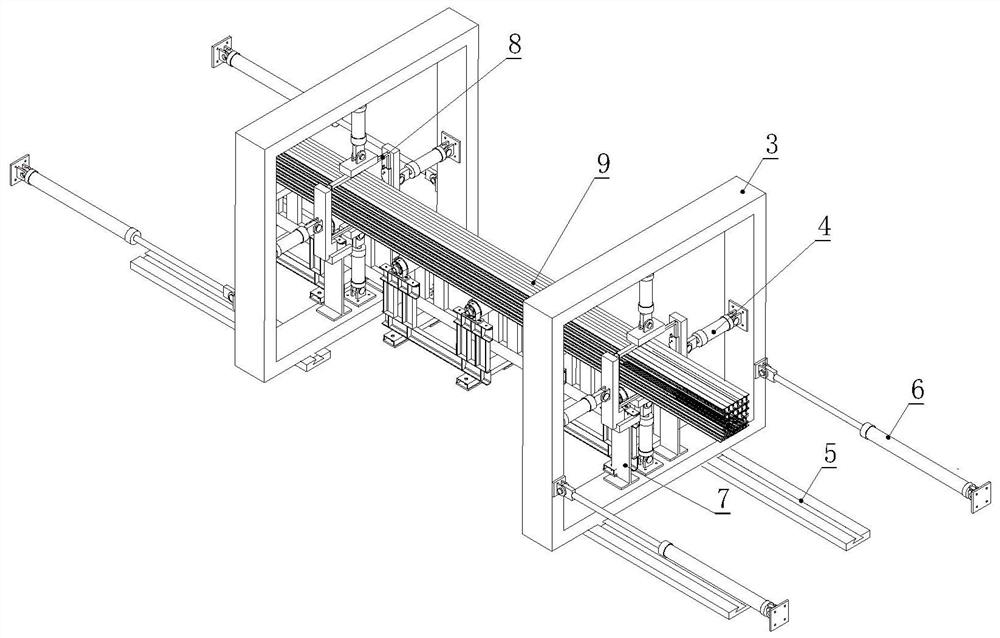

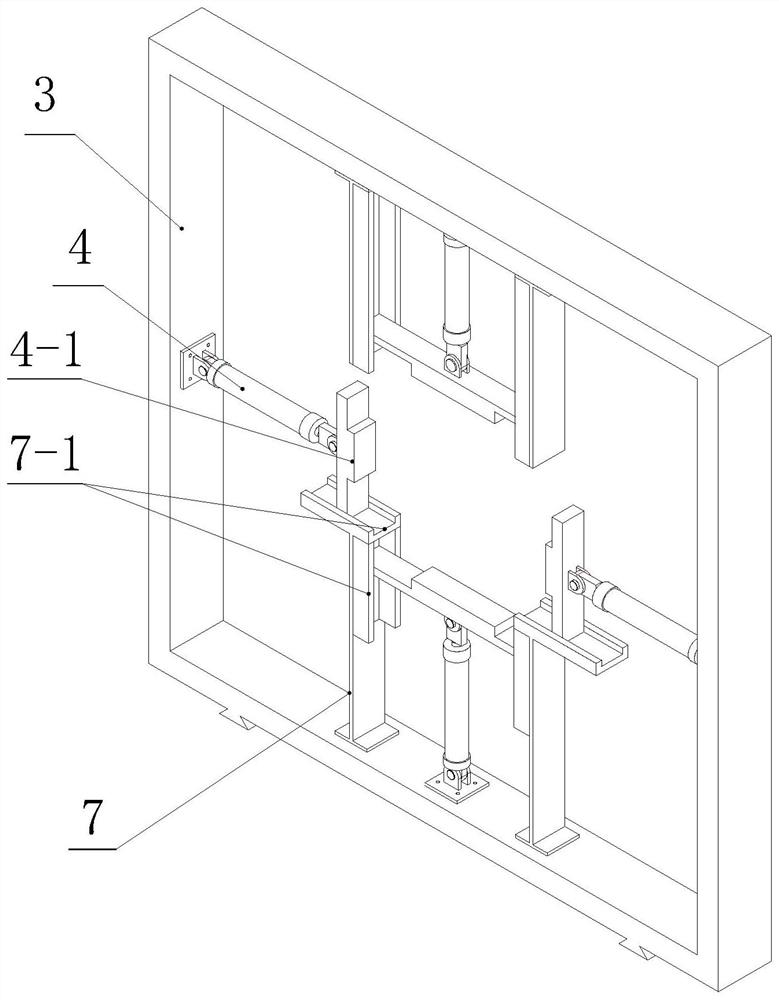

[0023] See figure 1 , figure 2 , the energy-saving section steel binding device includes a binding frame 3, which forms a sliding connection with the support guide rail 5, and the support drive cylinder 6 is connected with the support guide rail 5. Four push cylinders 4 and push support are arranged on the tie frame 3 Seat 7, the end of the air pressure rod is provided with a push block 4-1 to push along the push guide groove 7-1.

[0024] The binding frame 3 placed with the clamp 8 enters the station along the support guide rail 5 under the action of the support driving cylinder 6, so that the clamp...

Embodiment 2

[0027] This embodiment provides an energy-saving section steel binding device using a hexagonal clamp,

[0028] On the basis of Embodiment 1, the original push block 4-1 is replaced with a special-shaped push block 11, and the hexagonal clamp 10 is pushed. Composite steel palletizing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com