An energy-saving section steel automatic packing device and process

An energy-saving, section steel technology, applied in the direction of packaging, strapping materials, strapping machine parts, etc., can solve the problems of increasing the cost of use, increasing the cost and burden of pollution control, etc., to achieve fast strapping, neat and beautiful stacking, and less The effect of small production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

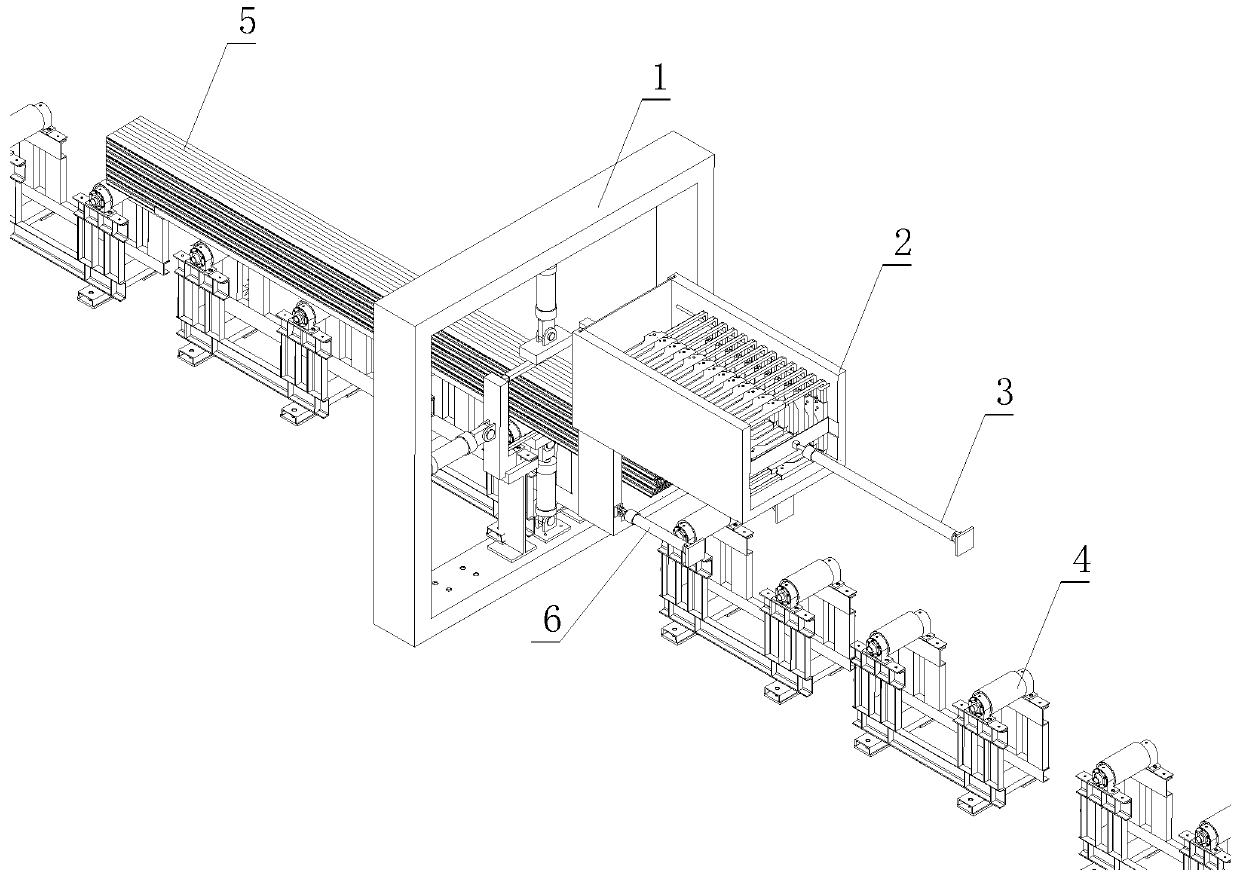

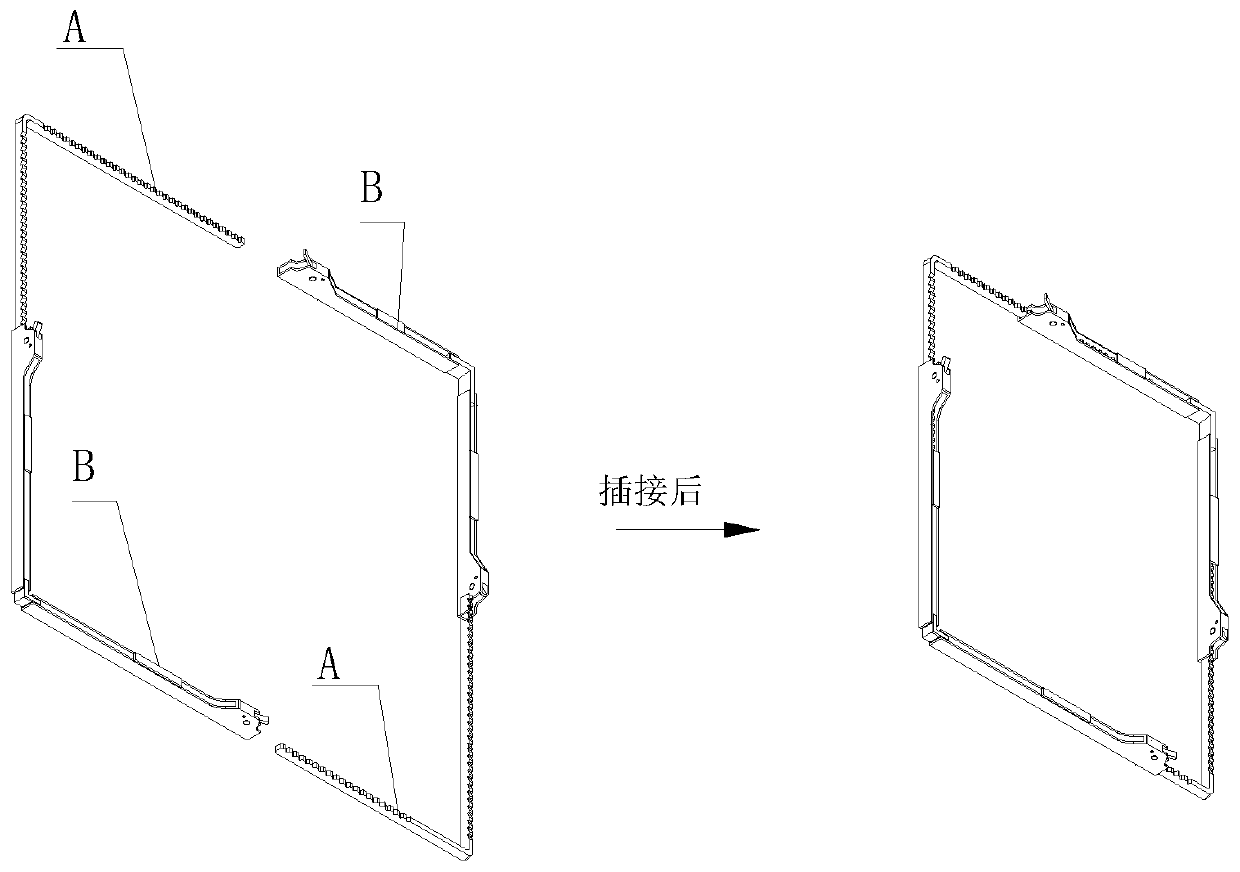

[0040] See Figure 1~ Figure 7 , what this embodiment provides is an energy-saving section steel automatic binding device, which uses a clamp as a binding piece for binding section steel stacking, see Figure 1-2 , there are two identical racks A and racks B staggered to form a mouth-shaped collar. Since the pawls set by the racks and the ratchets of the racks form anti-reverse sliding, so by pushing the racks or racks You can shrink the collar to complete the bundled pallet, and keep it tight.

[0041] As shown in Figure 1, the device includes a mouth-shaped support 1, a jig delivery box 2 for transporting jigs, a jig delivery rod 3 for pushing the jig into the station, a delivery roller 4 for transporting pallets, and a jig delivery box driving cylinder 6 ;

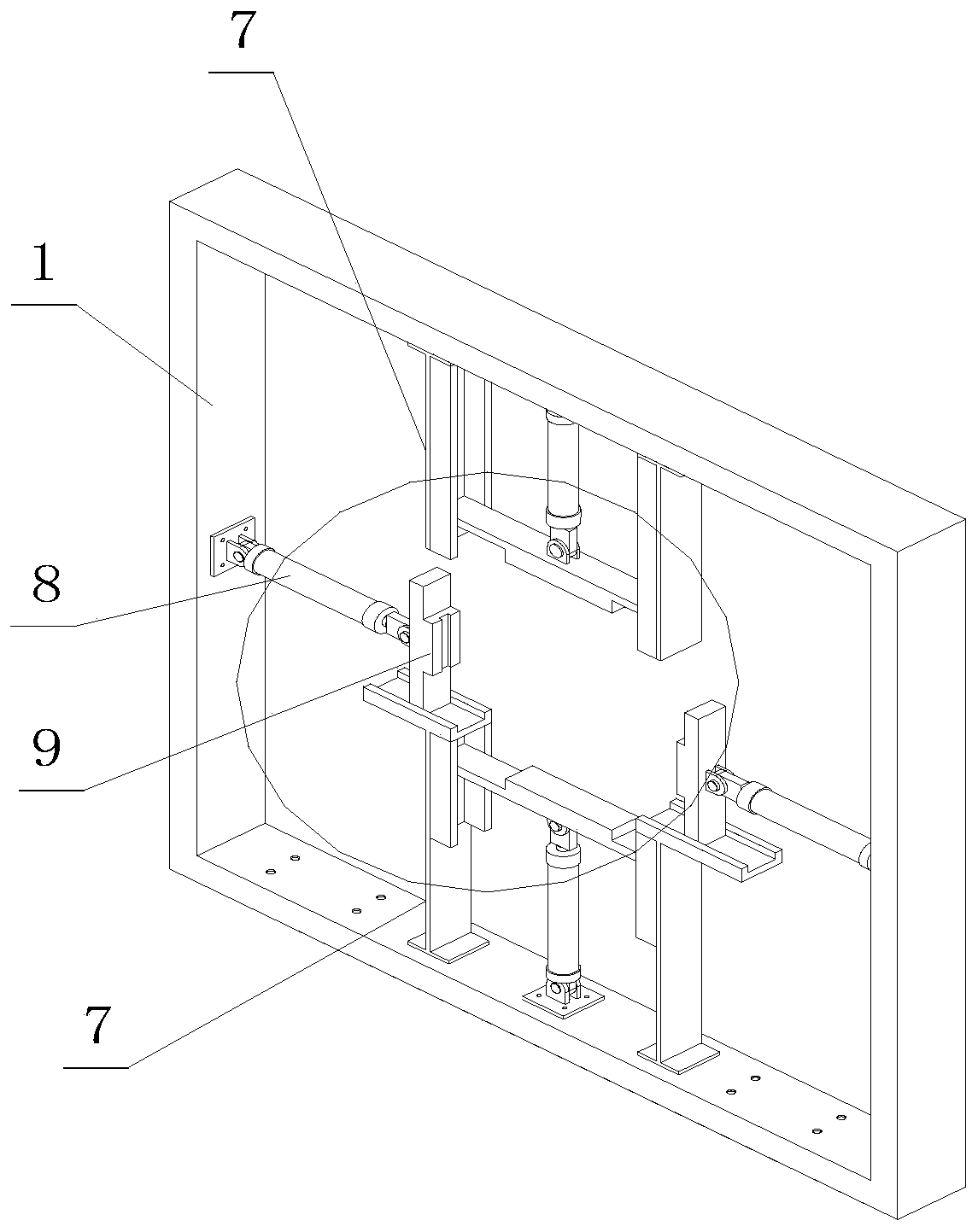

[0042] See figure 2 , image 3 , four jacking cylinders 8 are arranged axially in the mouth-shaped support 1, and a jacking bracket 7 is arranged; the end of the jacking cylinder 8 is provided with a jacking block ...

Embodiment 2

[0047] See Figure 6 , what this embodiment provides is an energy-saving section steel automatic binding device, and the difference from Embodiment 1 is that the mouth-shaped support 1 is replaced with a door-shaped frame 18, and the clamp push plate 14 is not provided, and two clamp conveying rods pass through instead. The push block pushes the clamp.

Embodiment 3

[0049] Provide a kind of section steel automatic binding process using the above-mentioned device, comprising Figure 9 Steps shown:

[0050] Step 1. Move the jig transport box to the top of the push bracket, push the jig through the conveying mechanism, and make the jig fall onto the push bracket along the limit groove;

[0051] Step 2, the stacked section steel enters the binding station through the conveying roller, so that the stacked section steel is stacked into the clamp collar;

[0052] Step 3, the push mechanism on the strapping frame pushes the fixture to shrink the collar of the fixture until the fixture fits on the stacking surface of the section steel;

[0053] Step 4, drive the conveying roller to make the pallet that has been bundled at one end pass through the strapping frame, and make the other end go over the strapping frame,

[0054] Step 5, move the jig transport box to the top of the push bracket, push the jig through the conveying mechanism, and make the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com