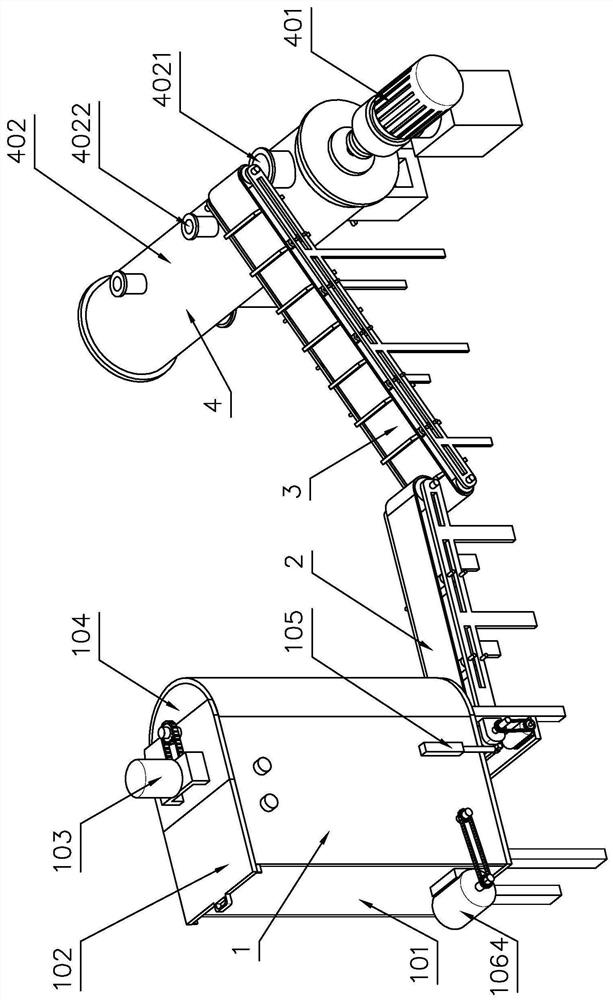

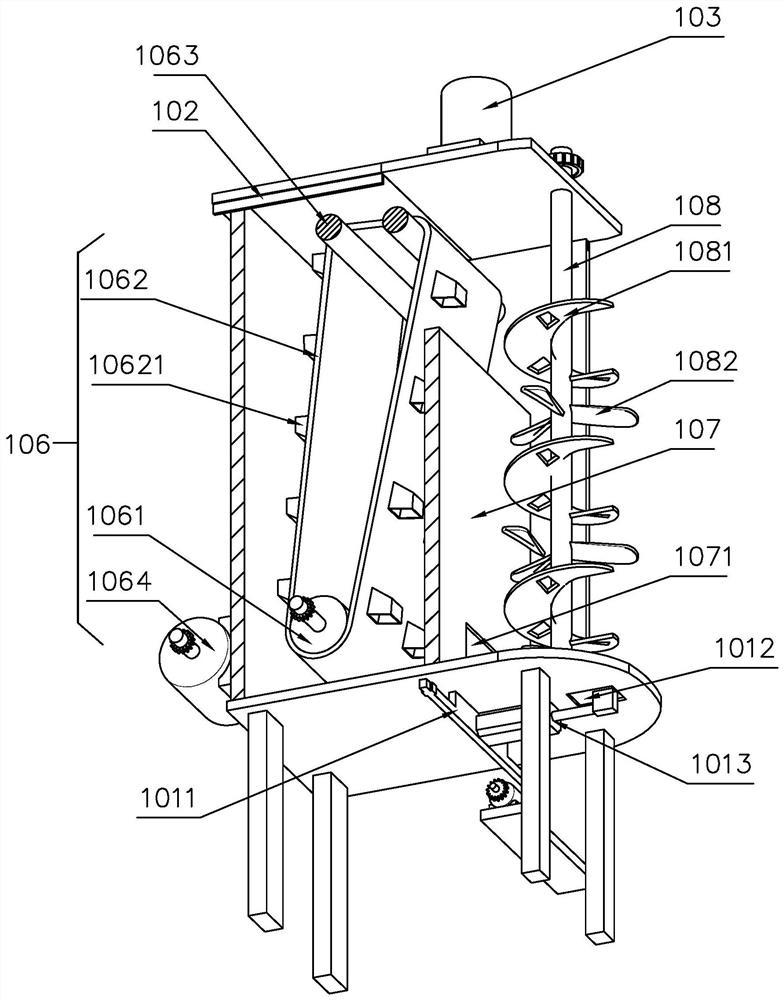

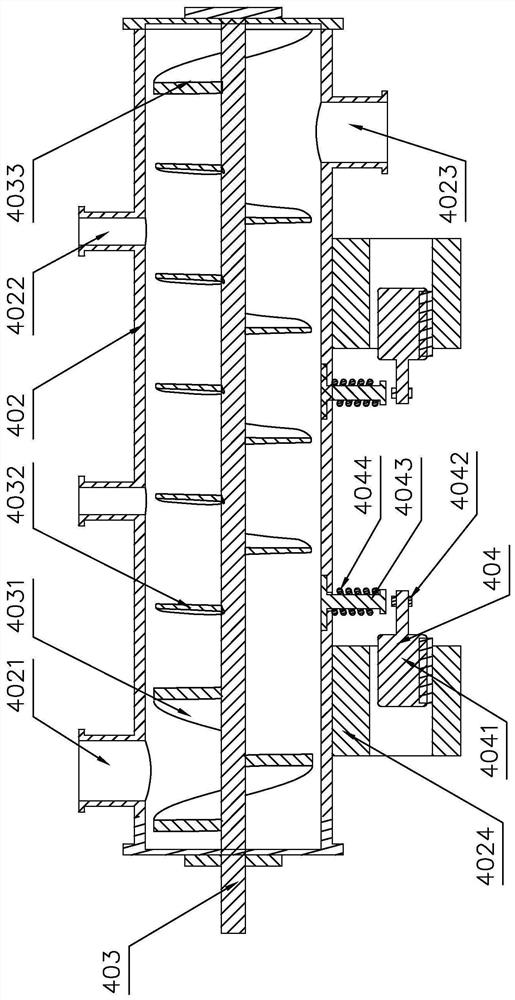

Water-soluble fertilizer mixing production equipment and water-soluble fertilizer preparation method

A production equipment and water-soluble fertilizer technology, applied in the field of water-soluble fertilizer mixed production equipment, can solve the problems of obvious moisture absorption, heat accumulation, fertilizer agglomeration, etc., and achieve the effect of avoiding the accumulation of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: as Figure 5 shown;

[0043] 1) Calculate the weight of material elements and prepare ingredients according to the composition ratio;

[0044] The specific formula of water soluble fertilizer is as follows:

[0045] Urea (powder, 46-0-0) 210-212 parts, monoammonium phosphate (12-61-0) 38-334 parts, potassium nitrate (13-0-46) 438-442 parts, boric acid (containing boron 17 %) 3.0-4.0 parts, EDTA chelated iron (containing iron 13%) 7.0-8.5 parts, EDTA chelated zinc (containing zinc 15%) 3.0-3.5 parts, EDTA chelated manganese (containing manganese 13%) 3.5-4.5 0.15-0.25 parts of ammonium molybdate heptahydrate (containing 54% molybdenum).

[0046] 2) Pre-mixing of trace elements, 3.5 parts of boric acid containing trace elements, 8.0 parts of EDTA chelated iron, 3.3 parts of EDTA chelated zinc, 4.0 parts of EDTA chelated manganese, 0.2 parts of ammonium molybdate heptahydrate and 440 parts of nitric acid Potassium is premixed in proportion by a paddle mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com