Lifting unstacking trolley capable of walking and having plate material positioning function

A lifting, dismantling, and belt-moving technology, applied in the direction of destacking, conveyors, mechanical conveyors, etc. of objects, can solve the problems of inability to meet automatic replacement and automatic maintenance of feeding height, unfavorable automatic production, and low production efficiency, etc. Improve the efficiency of feeding, reasonable structure design, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

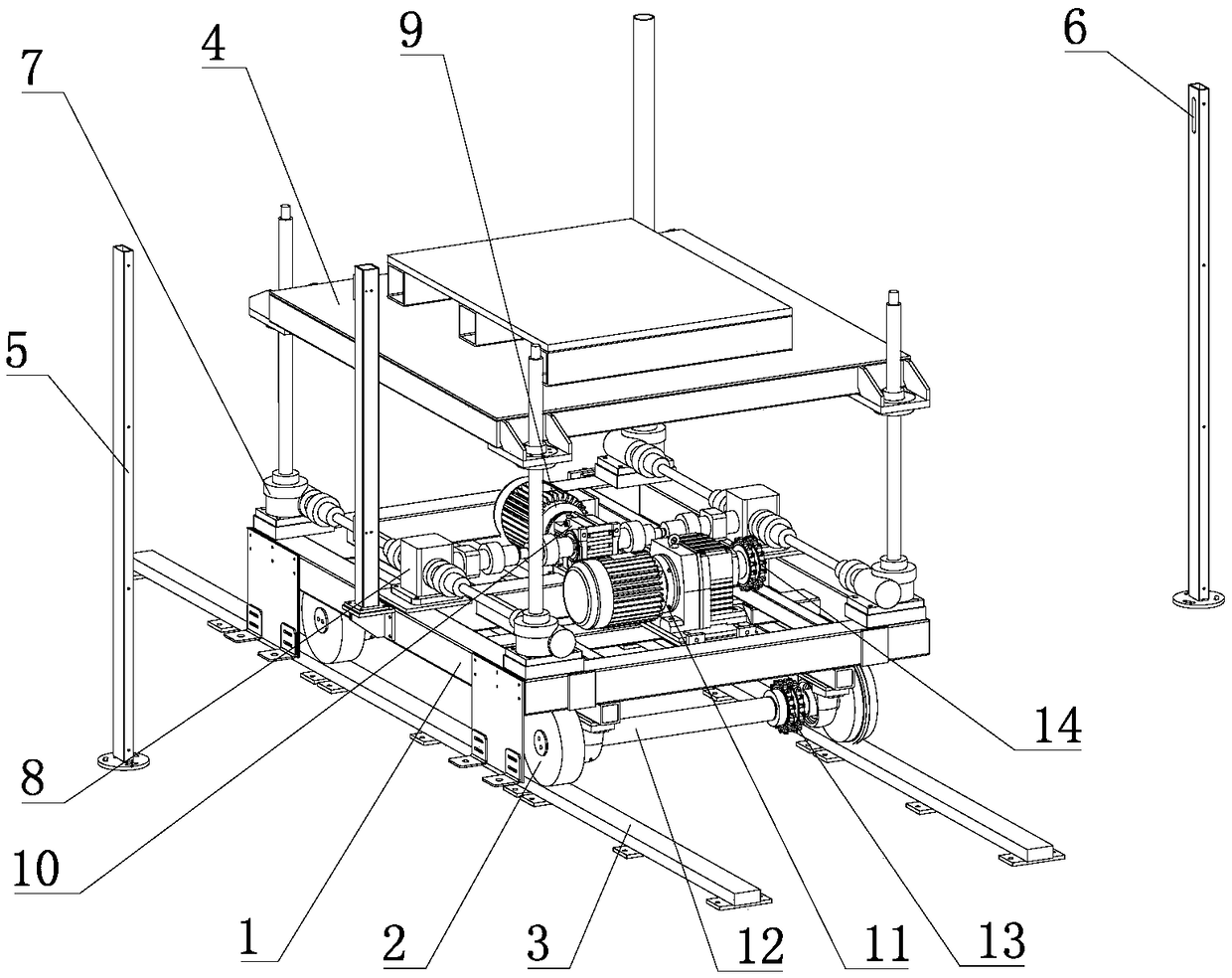

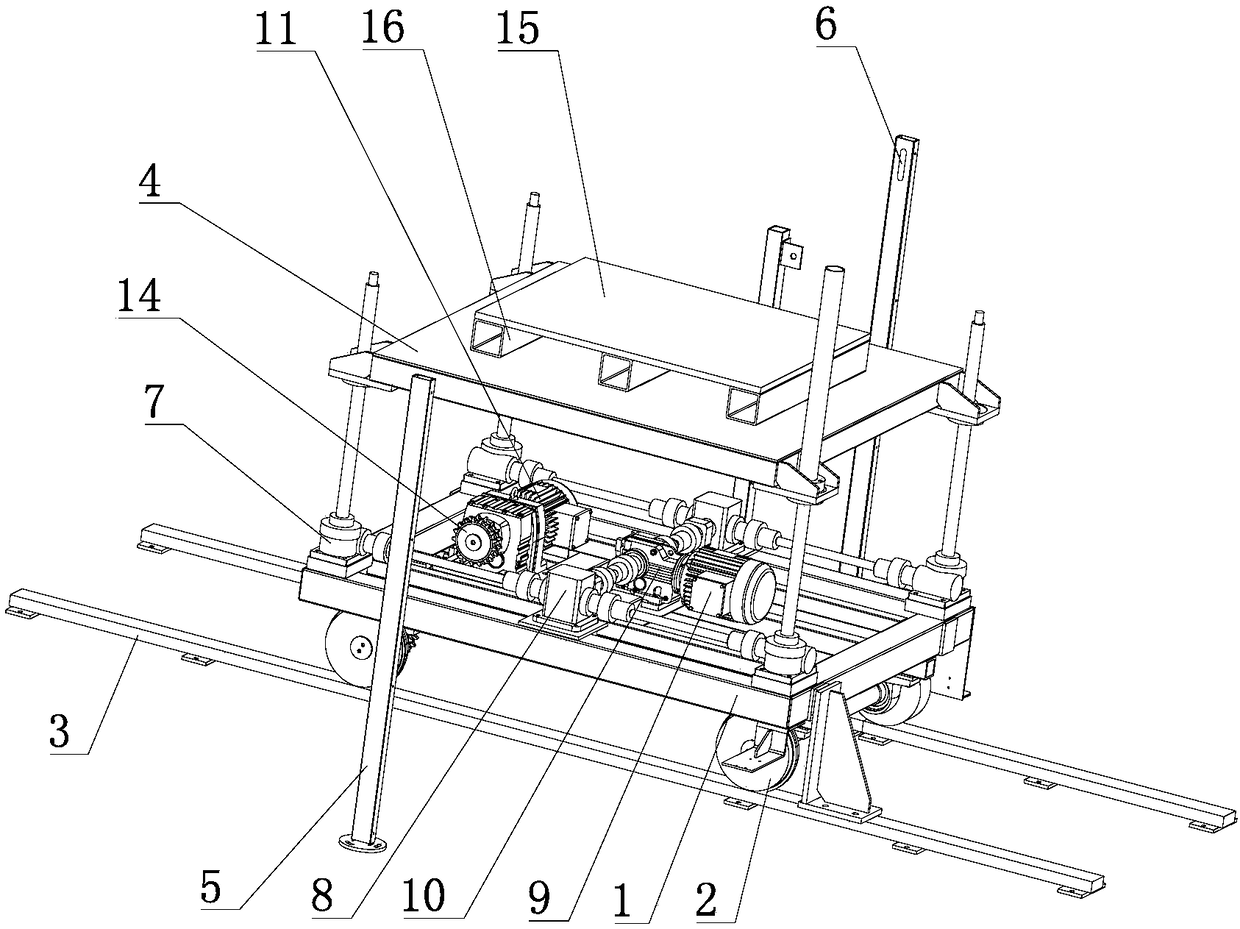

[0014] Such as Figure 1-2 As shown, a lifting and unstacking trolley capable of walking with sheet material positioning function includes a horizontally arranged frame 1, four wheels 2 are arranged at the bottom of the frame 1, and each wheel 2 is movable and fixed on a horizontal On the set guide rail 3, a running device connected to the wheels 2 is provided on the frame 1. The top of the frame 1 is connected to a horizontally arranged lifting material rack 4 through a lifting device, and vertically on the corresponding positions on both sides of the guide rail 3. Two bracing frames 5 are directly provided with, and a detection switch 6 is arranged on the opposite side of the top of the two bracing frames 5, and the detection switch 6, walking gear, lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com