Production technology of weft-knitted flight down feather

A production process and down technology, applied in weft knitting, yarn, textile and paper making, etc., can solve the problems of complex production process of production equipment, low three-dimensionality and aesthetics of fabrics, and achieve high aesthetics, strong three-dimensionality, Good thermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0023] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

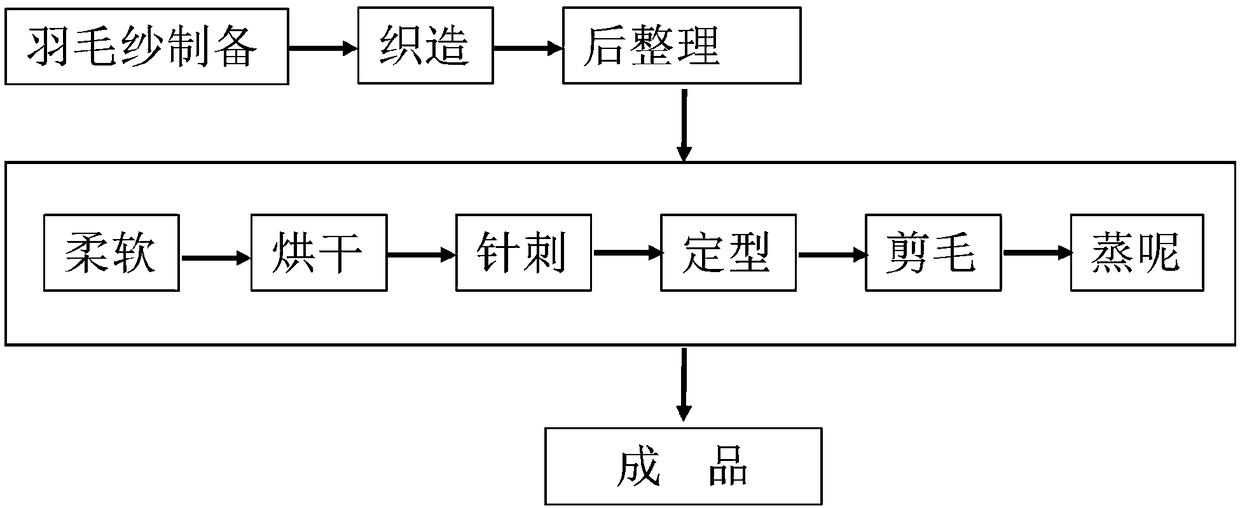

[0024] A production process for weft-knitting flying down, comprising the following steps:

[0025] (1) Feather yarn preparation, choose 100D / 36F polyester as the warp yarn, 70D / 7F nylon as the weft yarn, use a 20-needle crochet machine to weave the warp yarn and weft yarn, and the interval between the warp yarns is 6 needles, and then pass the cutter according to 1 / 3 Position ratio Cut the weft yarn to form feather yarn, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com