Multifunctional three-dimensional flowing simulation sealing device

A three-dimensional flow and sealing device technology, which is applied in the direction of production fluid, wellbore/well components, measurement, etc., can solve the problem that the pressure field and saturation field can not be tested at the same time, and the injection-production well group between injection and production wells cannot be realized at the same time. Research on oil displacement efficiency, inability to apply confining pressure and back pressure at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

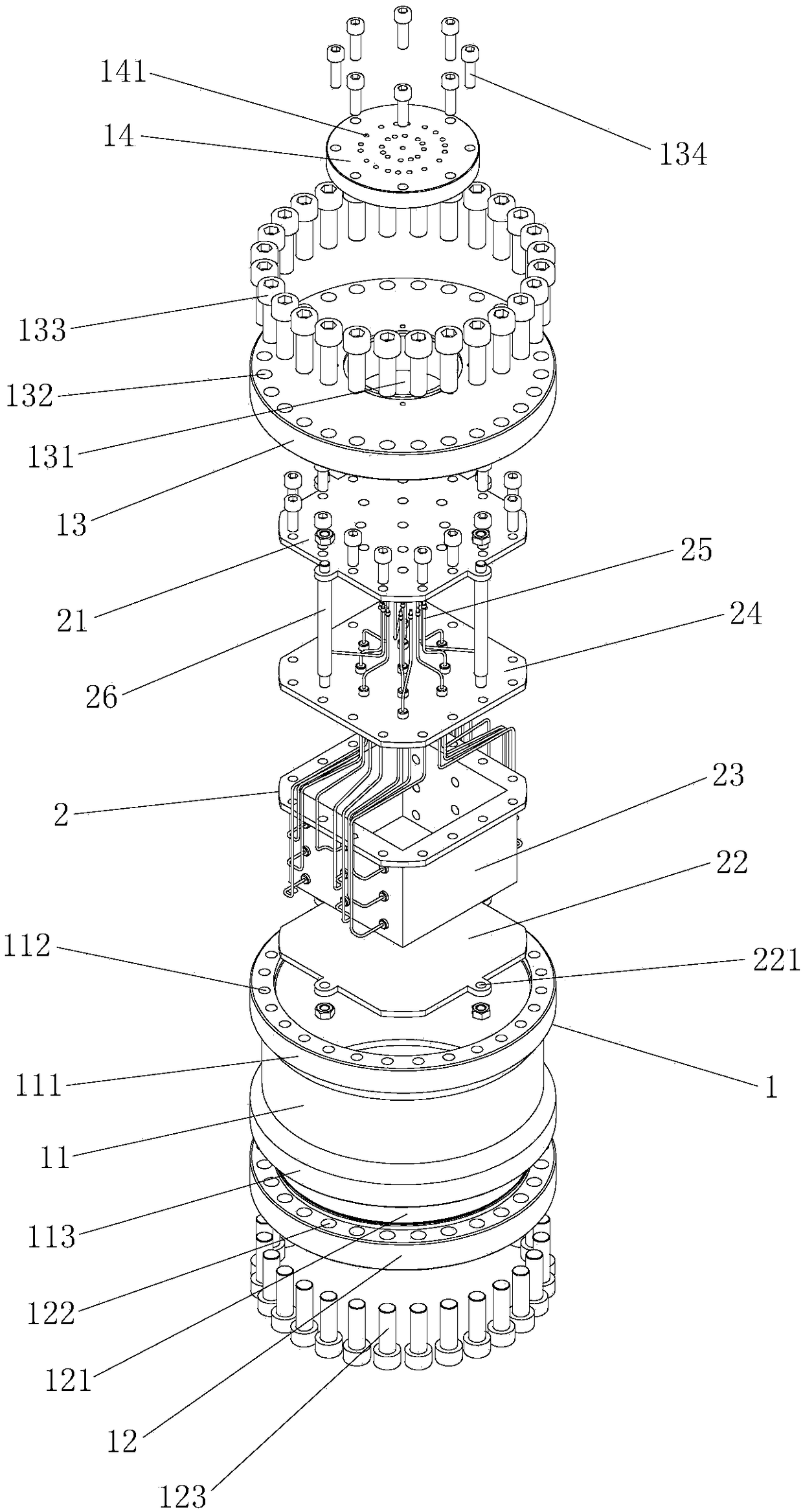

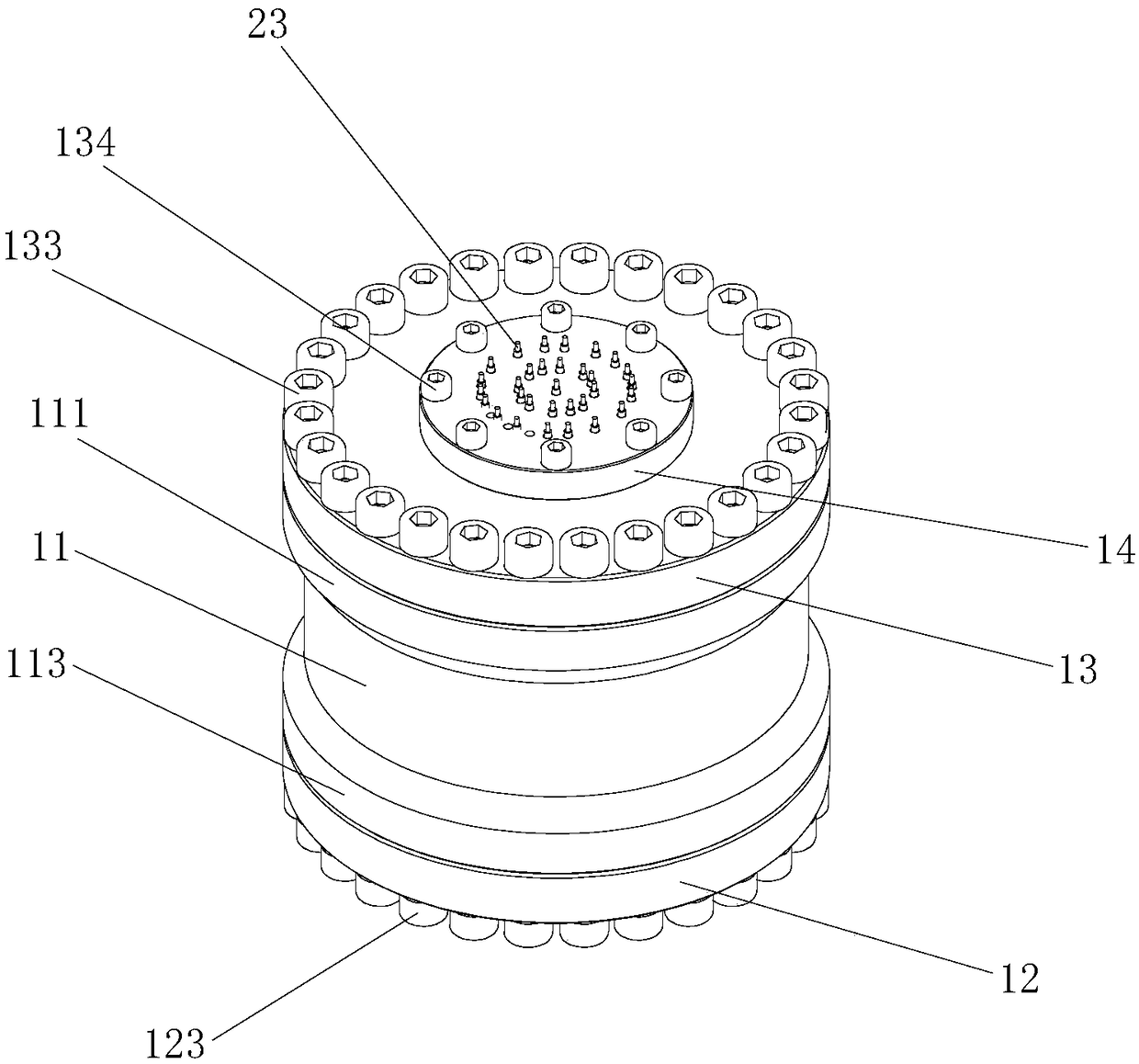

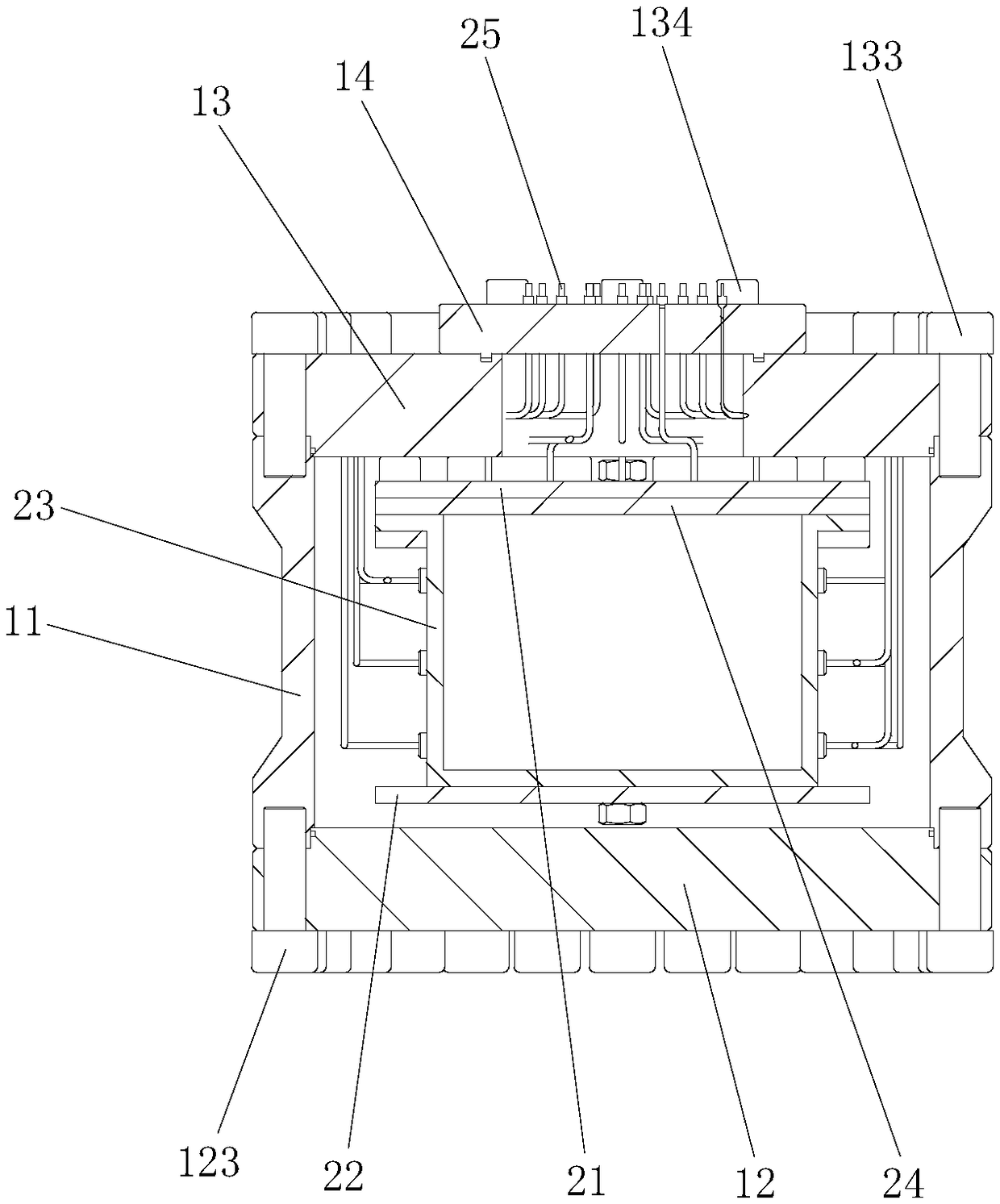

[0022] Such as Figures 1 to 3 As shown, the multifunctional three-dimensional flow simulation closure device of the present invention includes a model holder 1 and a model rubber sleeve assembly 2 matched and installed inside the model holder 1 .

[0023] The model holder 1 includes a holder body 11, a holder bottom cover 12 detachably assembled on the bottom end of the holder body 11, and a holder top cover 13 detachably assembled on the top end of the holder body 11 .

[0024] The top port of the holder body 11 protrudes uniformly outward along the circumference to form a ring-shaped top cover assembly platform 111, and a plurality of axially opened top cover assembly platforms are evenly arranged on the annular table surface of the top cover assembly platform 111. Hole 112; the bottom port of the holder body 11 protrudes uniformly outward along the circumference to form a ring-shaped bottom cover assembly platform 113, and the annular table surface of the bottom cover ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com