Machining device of shaft parts

A technology of shaft parts and processing devices, which is applied in the field of shaft parts processing devices, can solve the problems of limited processing accuracy, unguaranteed accuracy, and the inability of ordinary CNC lathes to achieve fully automatic processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

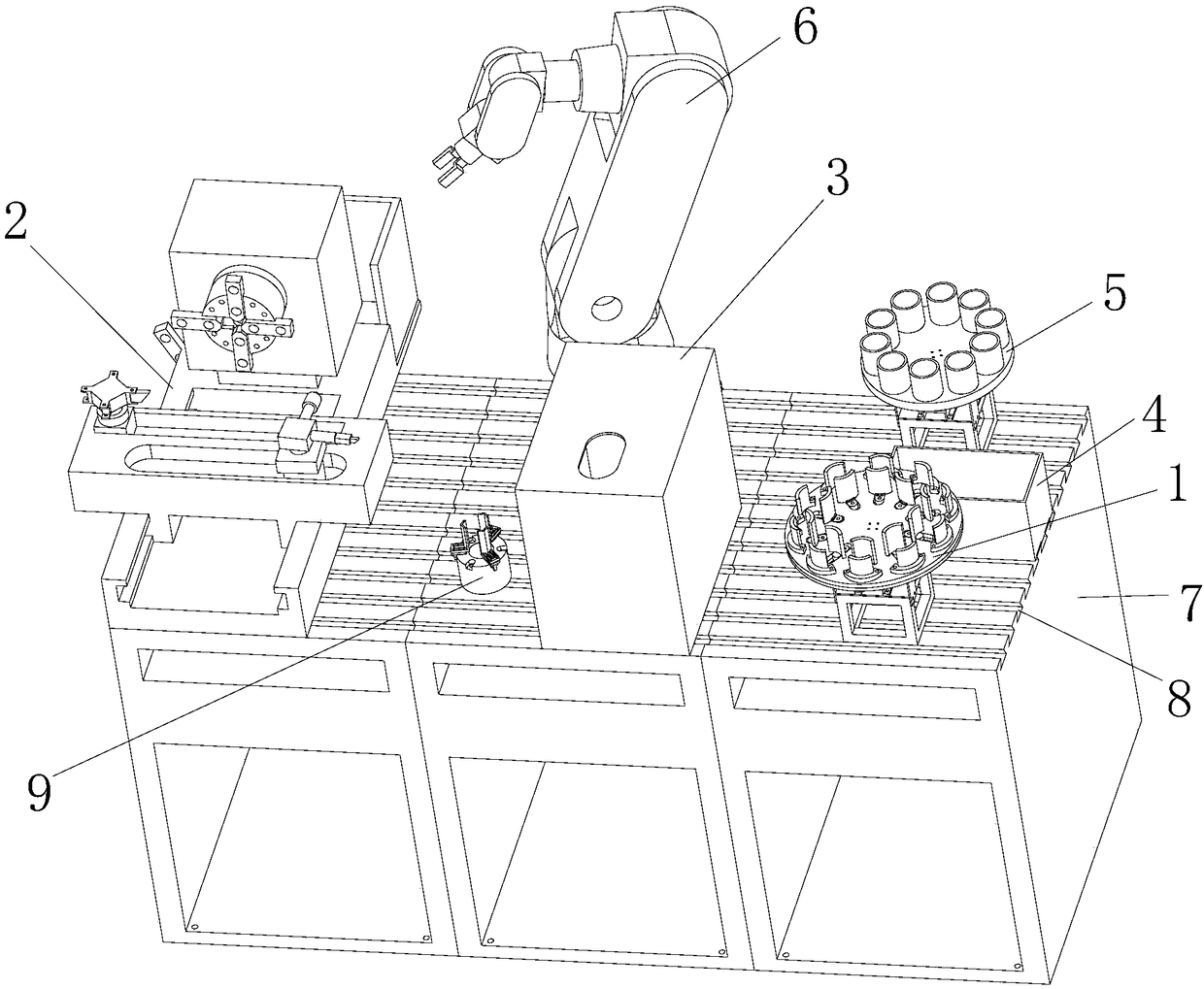

[0105] A processing device for shaft parts, comprising:

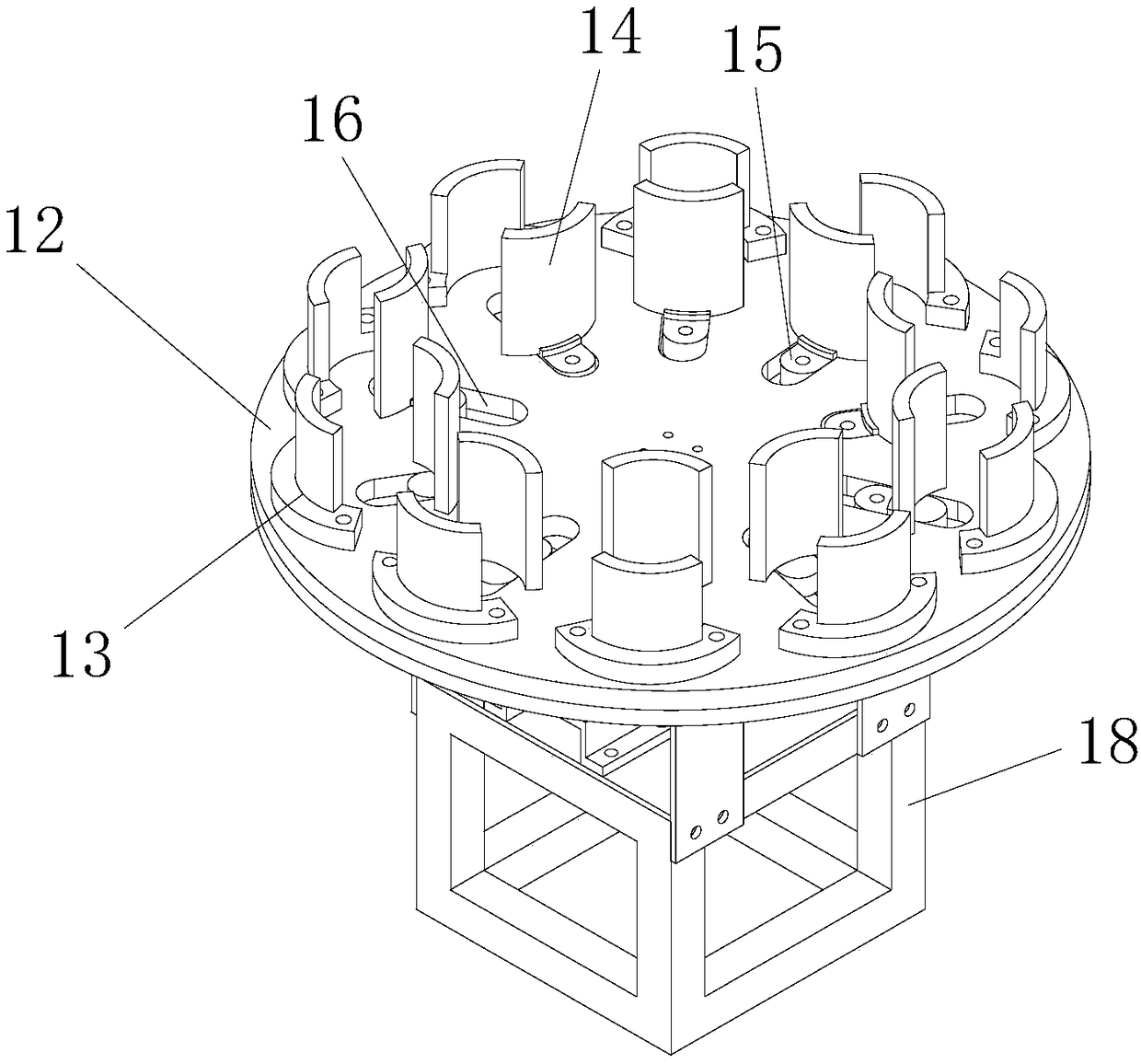

[0106] Feeding tray 1, used to place shaft parts to be processed;

[0107] Lathe 2, used to process shaft parts;

[0108] The detection mechanism 3 is used to detect whether the processing part of the shaft parts meets the processing requirements;

[0109] Defective product area 4, used to place shaft parts that cannot meet the processing requirements;

[0110] The discharge tray 5 is used to place and detect shaft parts that meet the processing requirements;

[0111] The mechanical arm 6 is used to grab the shaft parts to be processed from the feeding tray 1 and transfer them to the lathe 2 and the detection mechanism 3 in sequence. If the detection fails to meet the processing requirements, the shaft parts ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com