Heat dissipation module and electronic equipment

A heat dissipation module and housing technology, applied in mechanical equipment, electrical digital data processing, instruments, etc., can solve the problems of electronic equipment not being able to reach, cooling fans with low versatility, and achieve the goal of eliminating wind dryness and improving versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

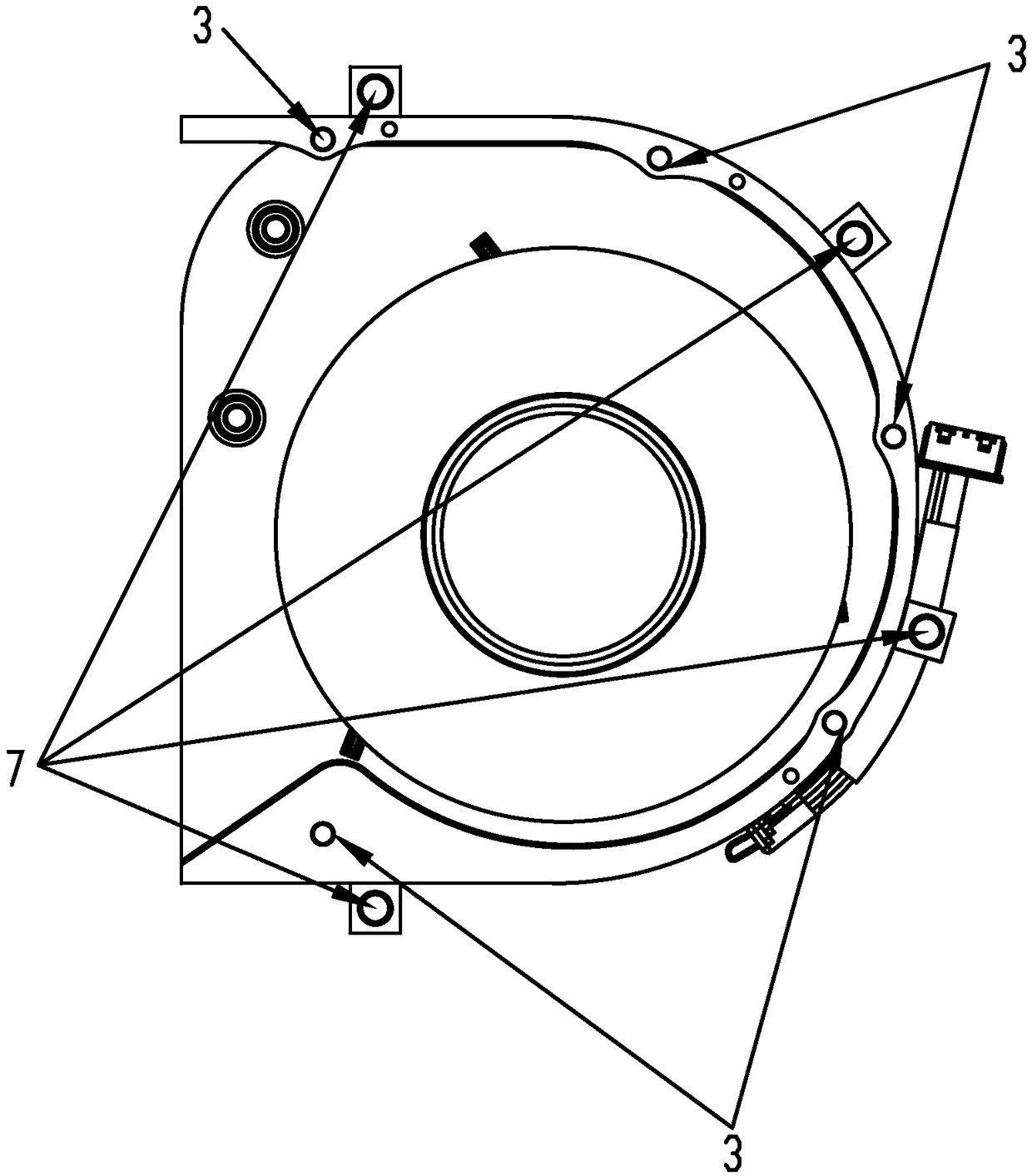

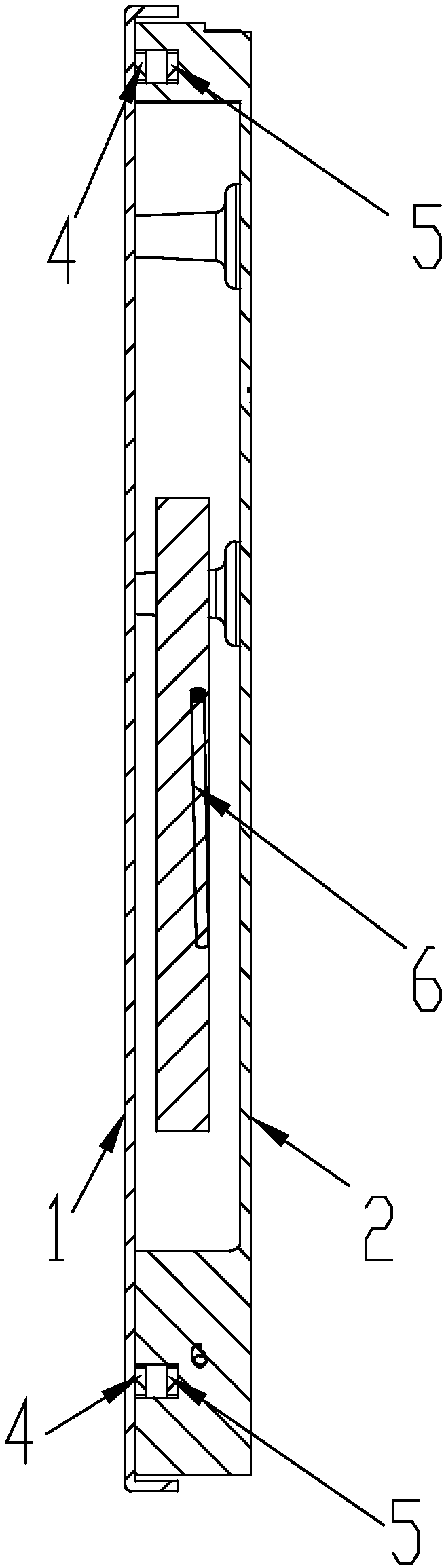

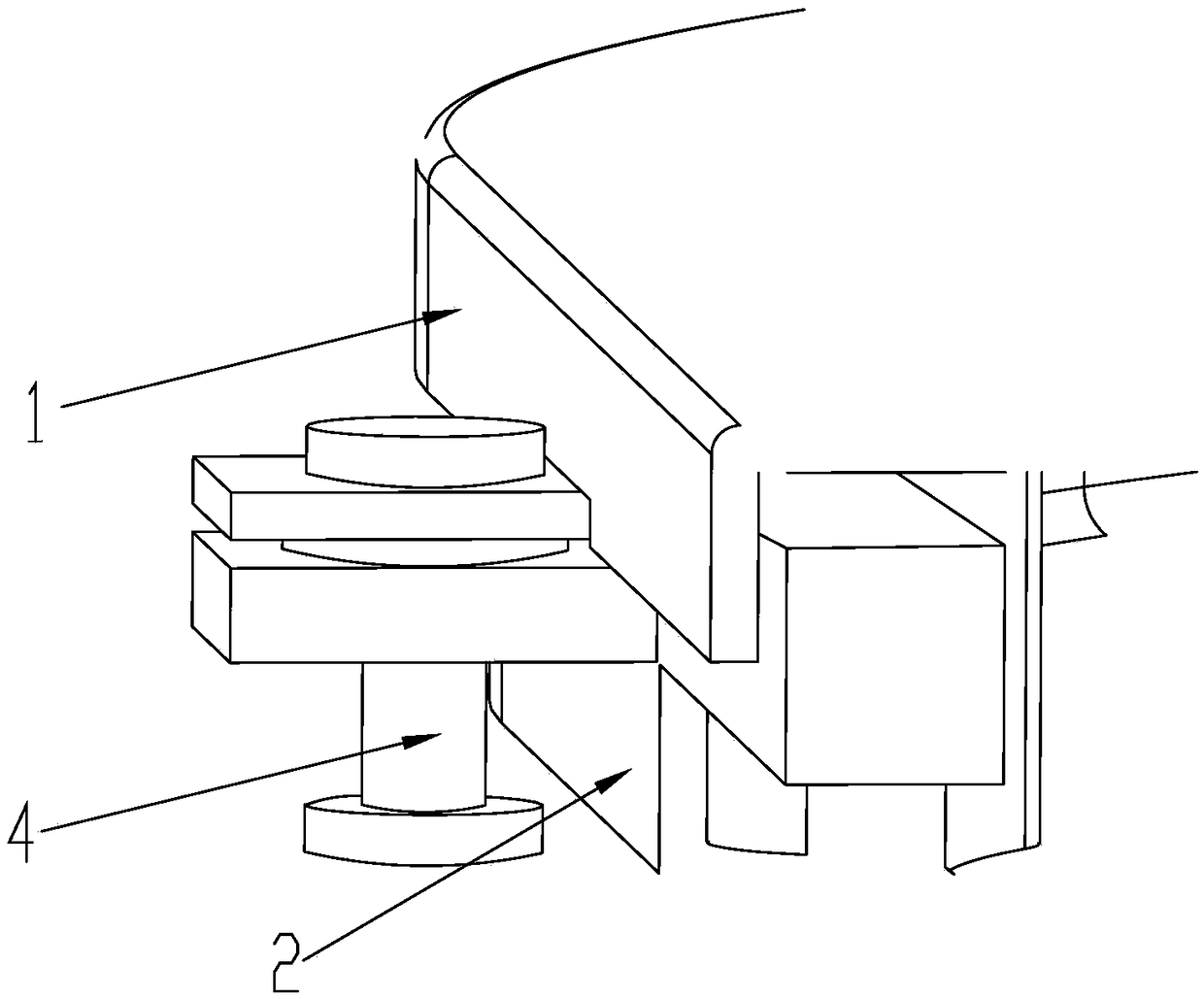

[0022] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] Various aspects and features of the invention are described herein with reference to the accompanying drawings.

[0024] These and other characteristics of the invention will become apparent from the following description of preferred forms of embodiment given as non-limiting examples with reference to the accompanying drawings.

[0025] It should also be understood that while the invention has been described with reference to a few specific examples, those skilled in the art can certainly implement many other equivalent forms of the invention, which have the features described in the claims and thus lie within the scope of the present invention. within the limited scope of protection.

[0026] The above and other aspects...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com