Staggered arm independent reducing wheel type waterproof pipeline robot

A pipeline robot and variable diameter wheel technology, which is applied in the field of robotics, can solve the problems of the pipeline robot's variable diameter method being rigid, inflexible, and prone to interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention will be further described:

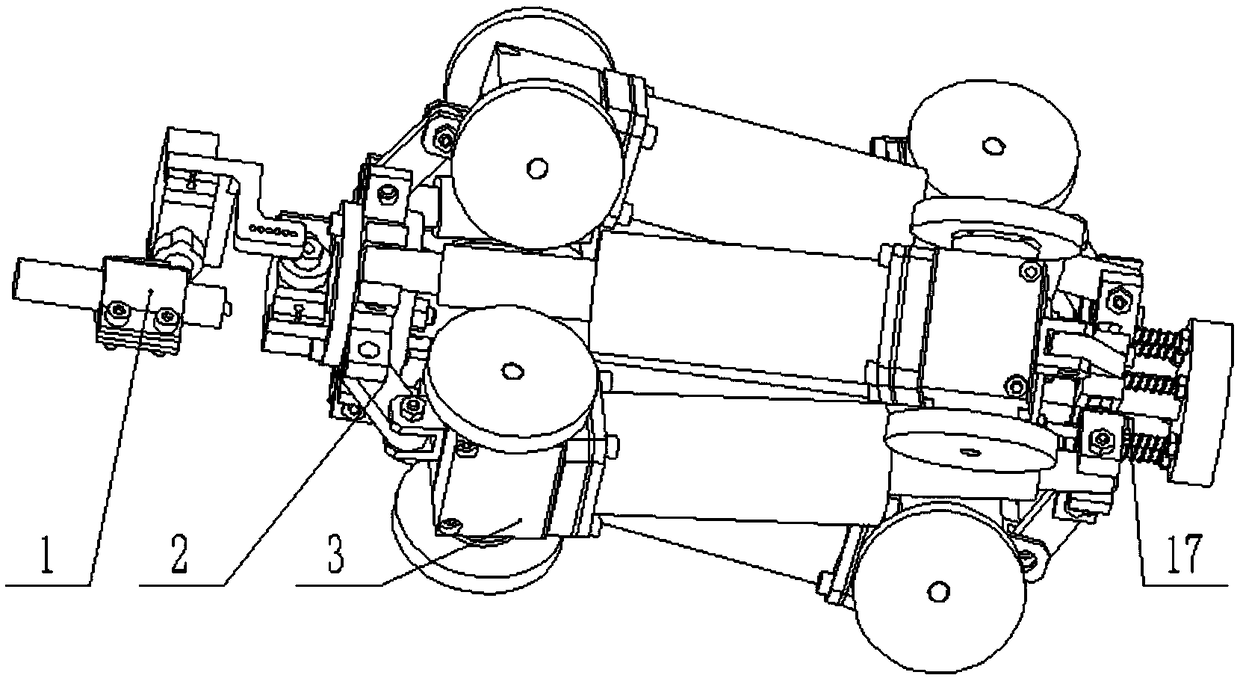

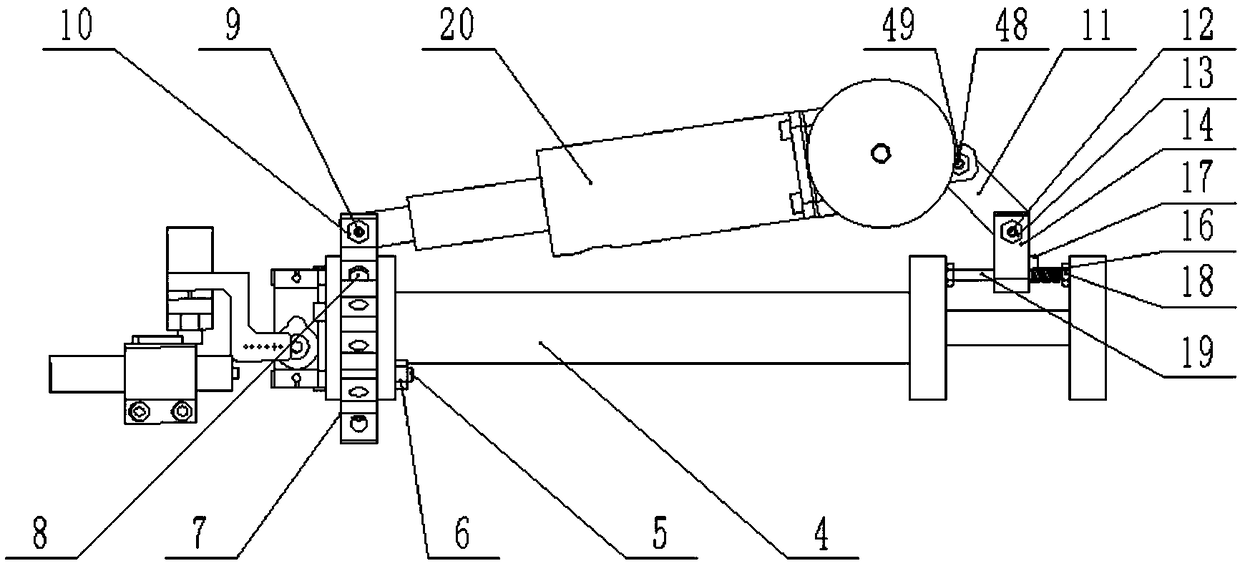

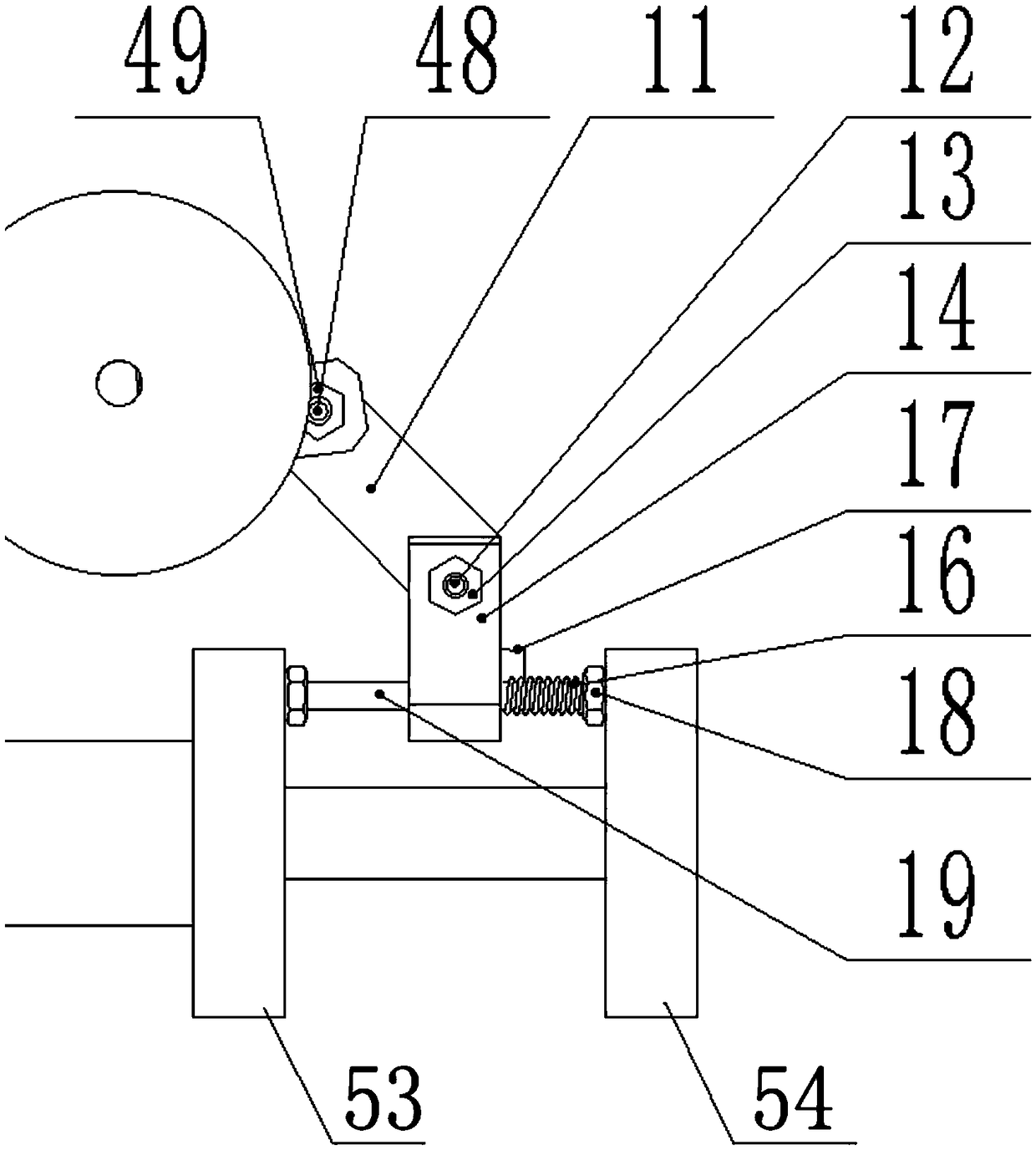

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, it includes an imaging device 1, a diameter reducing mechanism 2, a waterproof traveling mechanism 3 and an anti-seize pull ring 17.

[0033]The front end of the motor barrel 20 in the waterproof running mechanism 3 is provided with a positioning plate 32, and the motor 21 is positioned in the motor barrel 20 and is fixed on the positioning plate 32, which is convenient for installation and disassembly. The gap between the positioning plate 32 and the motor barrel 20 is provided with a positioning plate gasket 33 for sealing to prevent water from entering the gap between the positioning plate 32 and the motor barrel 20 . The front end of the gearbox spacer 31 is provided with a split gearbox, and the gearbox gasket 31 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com