Vision-guided automobile rear partition board assembling robot

A Vision-Guided, Rear Bulkhead Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

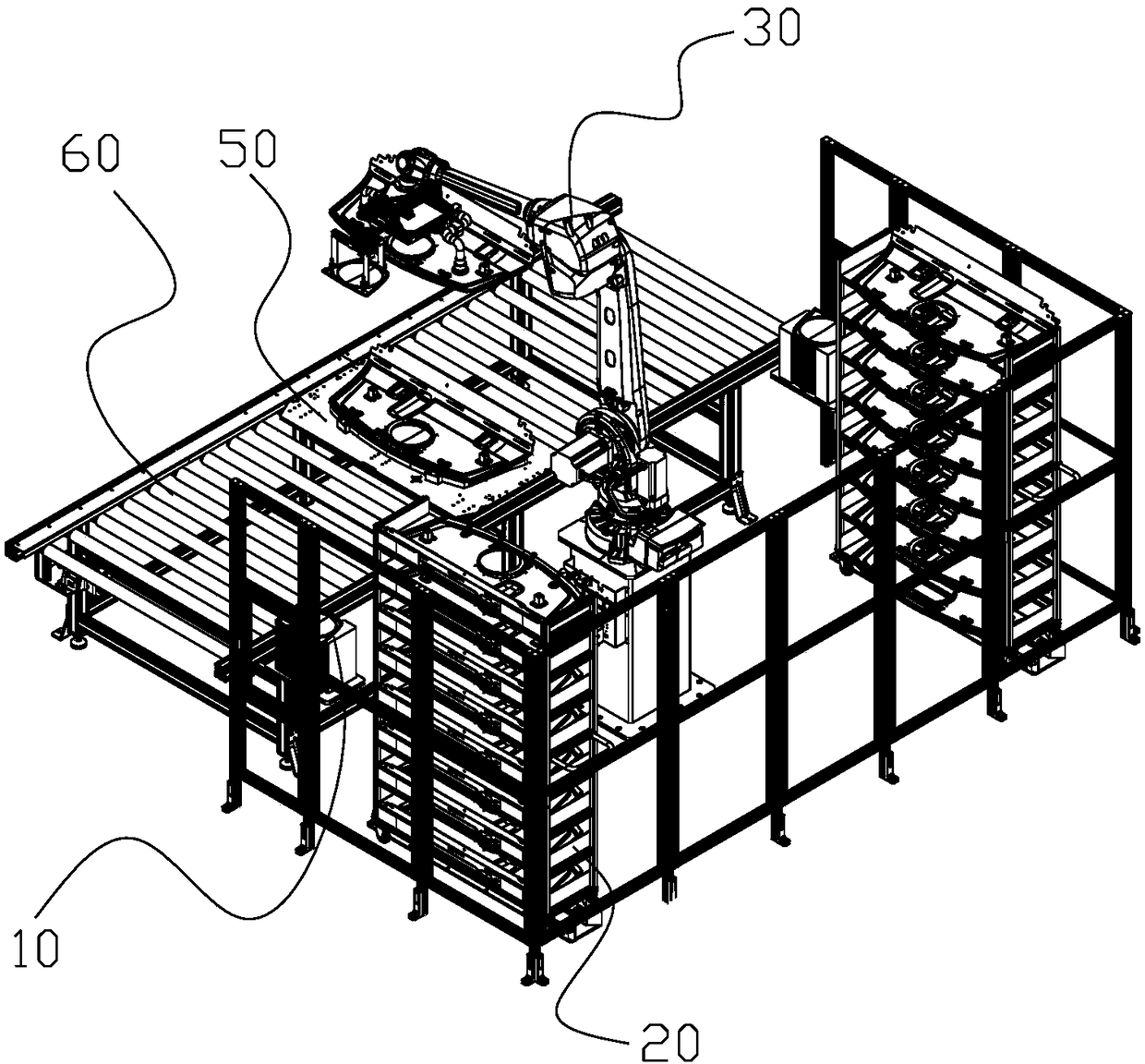

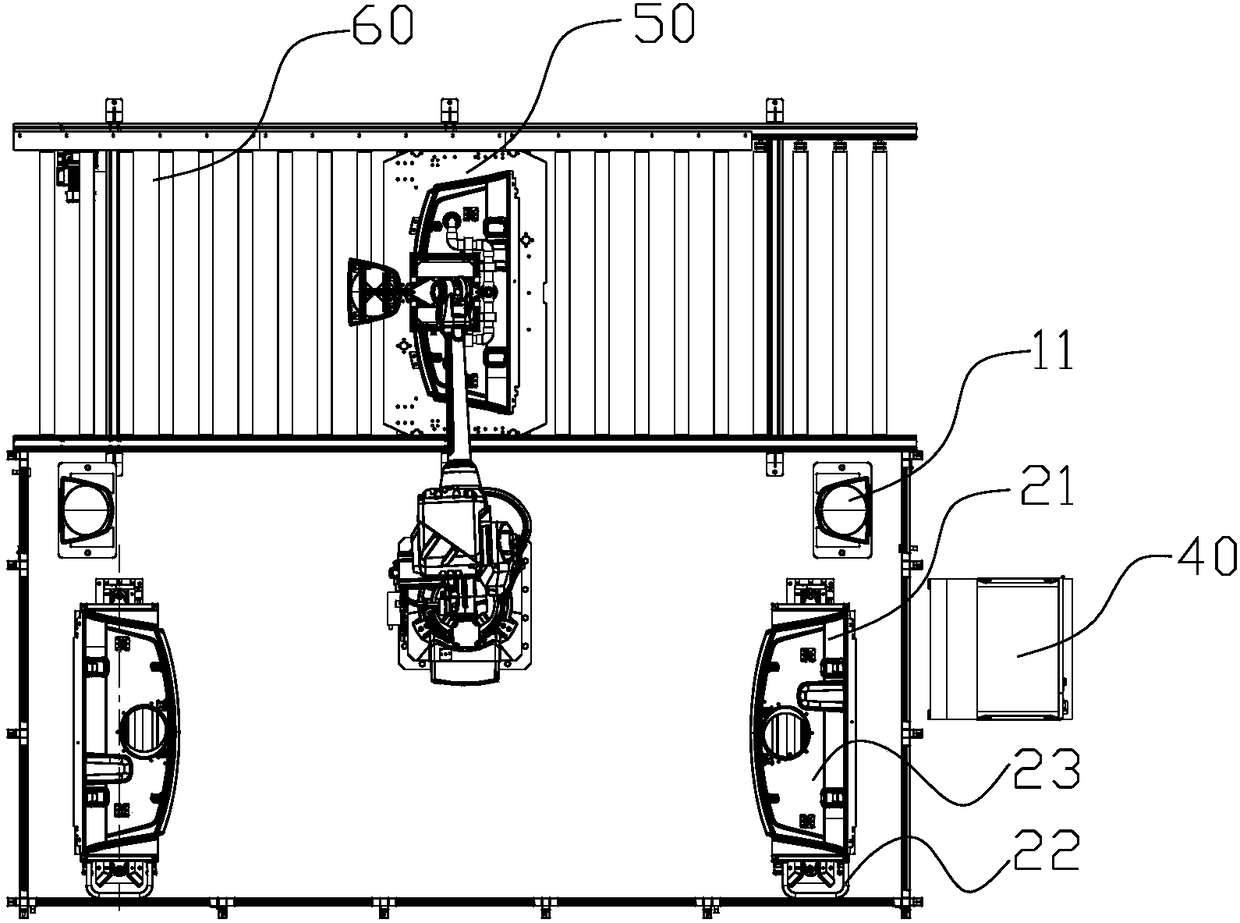

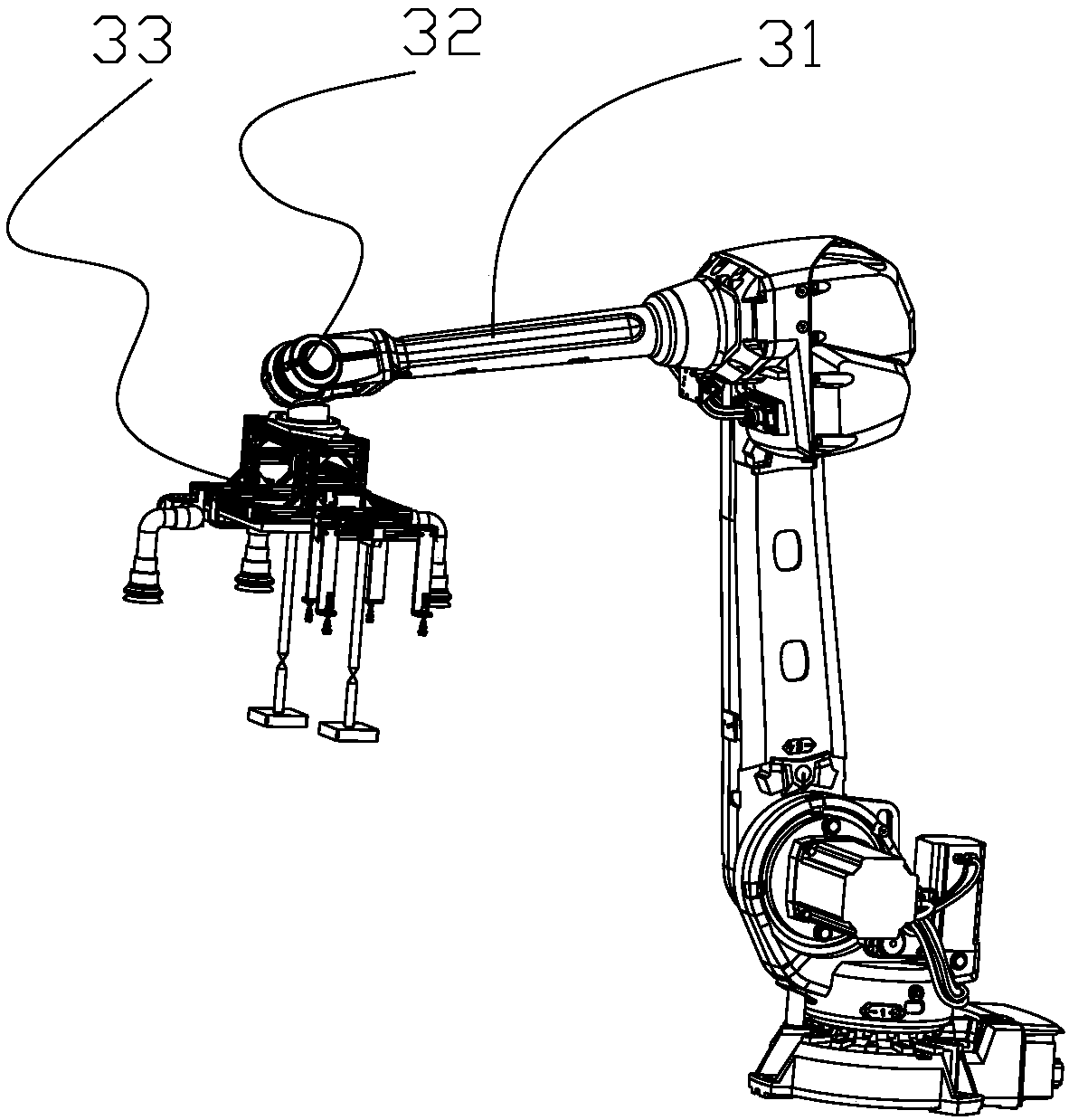

[0022] Please refer to figure 1 and figure 2 As shown, this embodiment provides a vision-guided automobile rear partition assembly robot, including a first feeding device 10 for placing a horn cover 11 and a second feeding device 20 for placing a rear partition 21 , also includes an articulated robot 30, a control unit 40 connected to the articulated robot 30, and a clamping device 50 for clamping the rear bulkhead of the automobile, wherein the end of the articulated robot 30 is provided with disassembly and assembly Executing device 33 , the destacking and assembling executing device 33 is provided with a visual positioning device and a sucker device, and the visual positioning device determines through the control unit 40 that the articulated robot 30 and the first loading device 10 After the relative position of the horn cover 11 and the relative position of the articulated robot 30 and the rear partition 21 of the vehicle on the second loading device 20, guide the artic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com