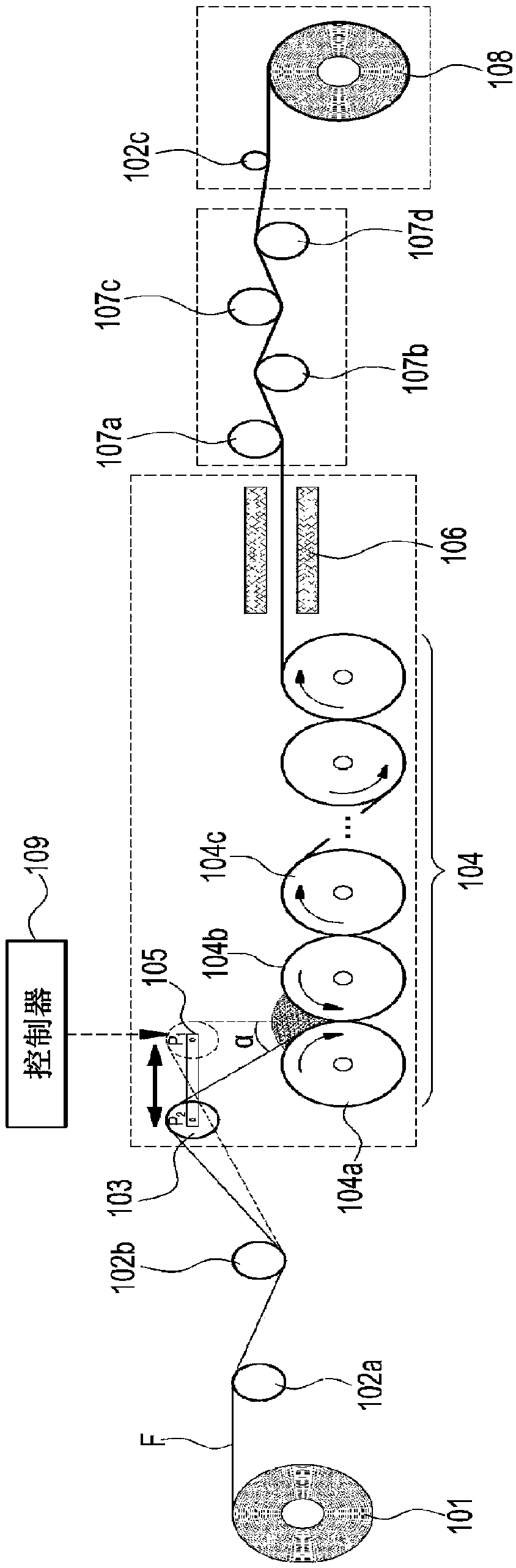

Apparatus for manufacturing tow prepreg and method for the same

A technology of prepreg and equipment, applied in the direction of devices and coatings for coating liquid on the surface, can solve problems such as hardening, and achieve the effect of precise control and reduction of heat treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

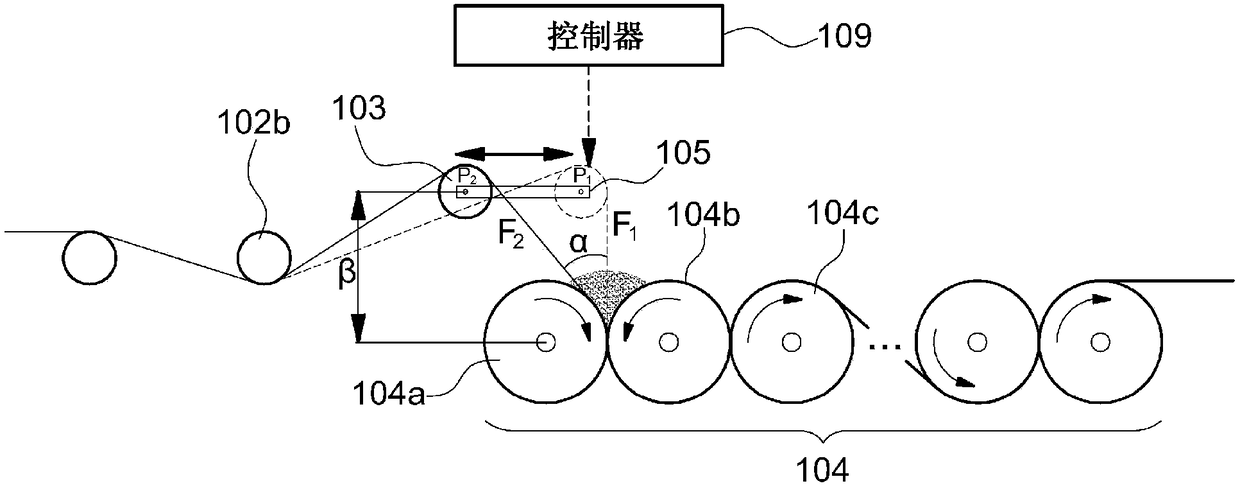

[0095] Carbon fibers were installed in the supply member 101; the fibers were unwound; and the fibers were passed through rollers in the fiber supply section (where the rollers were heated to 80° C.) to heat and expand the carbon fibers.

[0096] In order to manufacture a tow prepreg which is commonly used and has a resin content of 30%, the width of the fibers passing through the expander roll is controlled such that α is 20°.

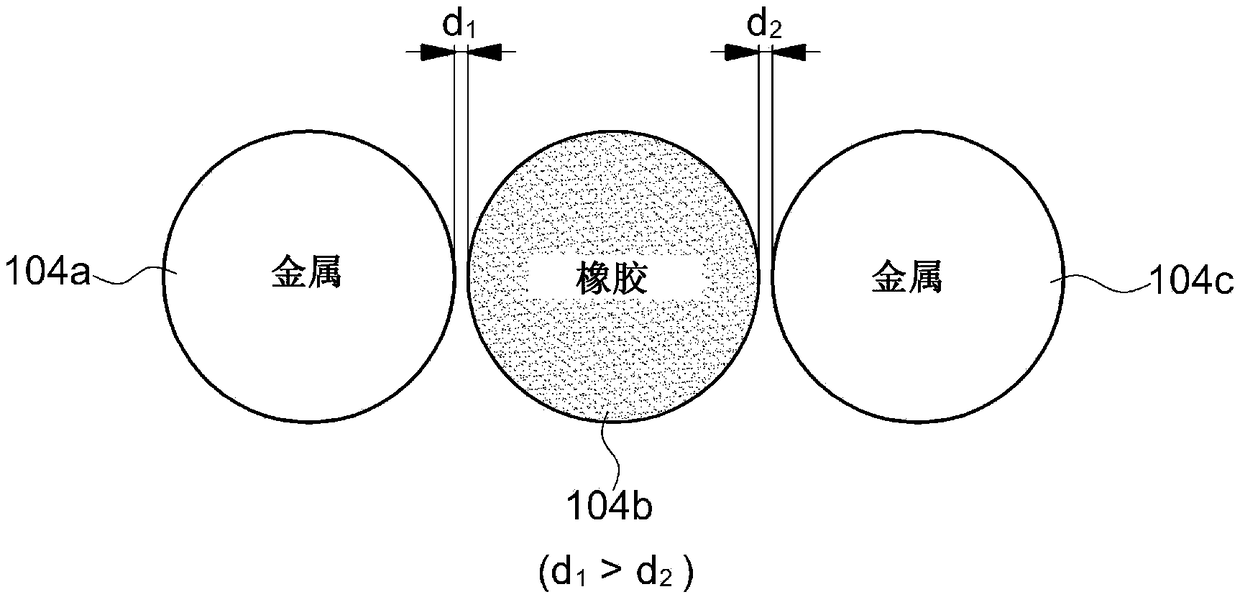

[0097] The fiber passes through the gap between the first roll (metal) and the second roll (rubber) heated to 80°C. In this case, the gap between the two coating rollers was set to 0.2 mm so that the resin was sufficiently coated between the carbon fiber bundles. Next, the gap between the second roll and the third roll heated to 80°C was set to 0.135 mm, and in this case, the gap between the second roll and the third roll was set in consideration of the influence of resin flow. The gap was adjusted so that the width of the fiber passing through the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com