Defective LED Removal Device

A light-emitting diode, defective technology, applied in the secondary processing of printed circuits, printed circuit repair/correction, semiconductor devices, etc., can solve problems such as defective light-emitting diodes, additional process quality problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

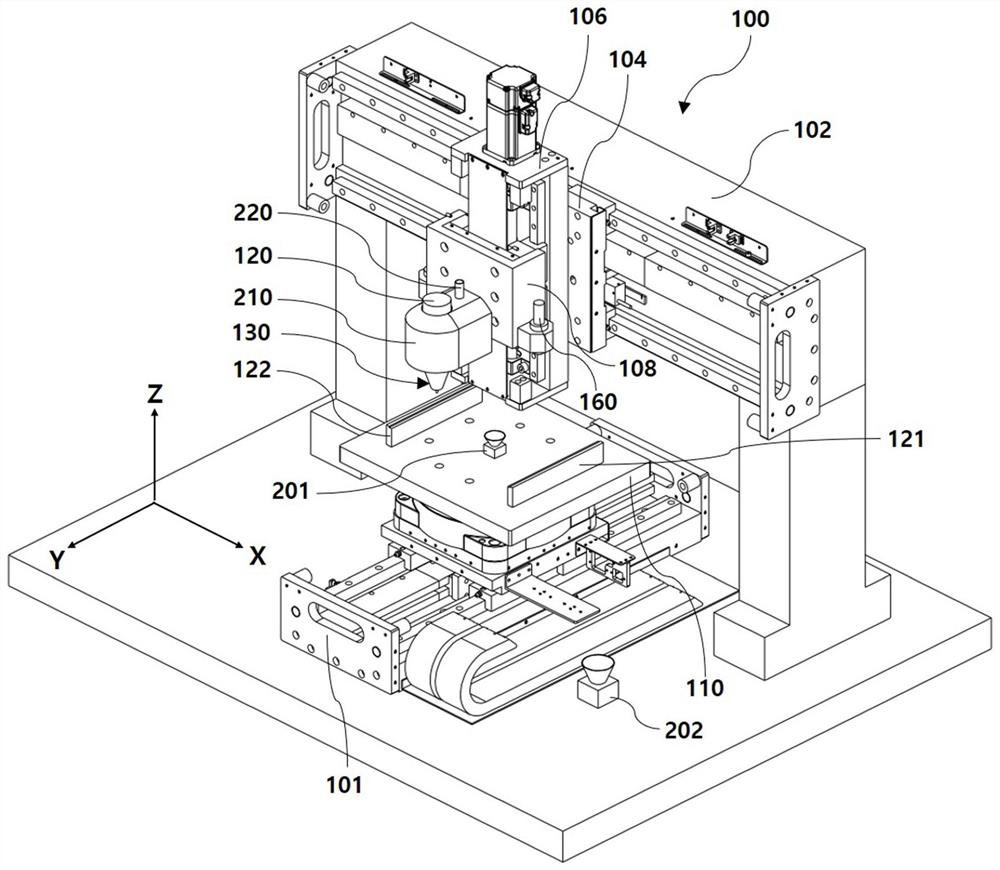

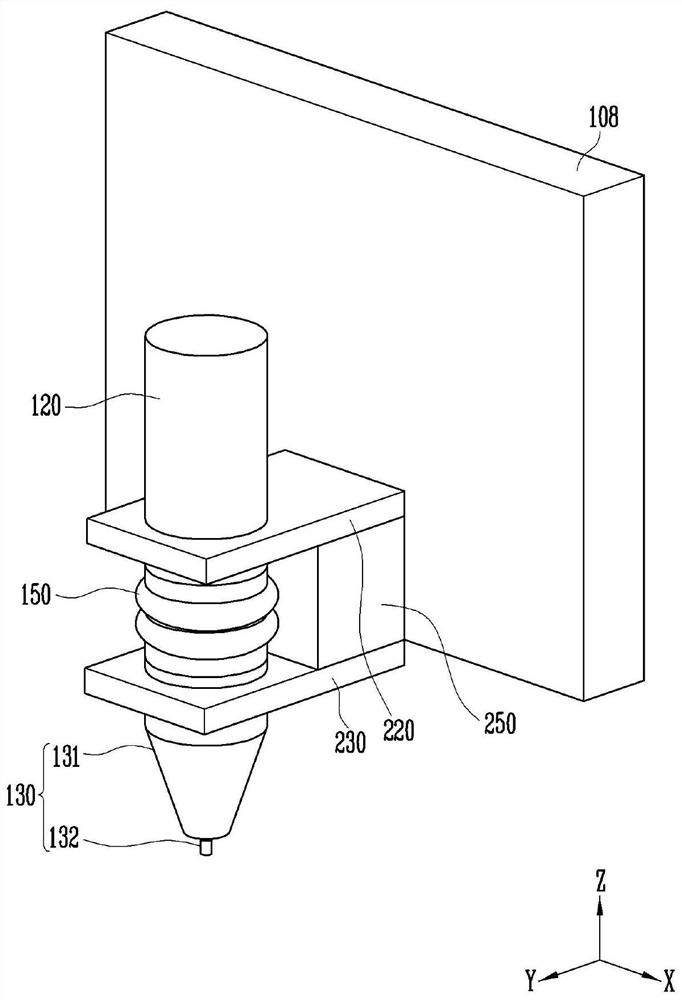

[0036] Hereinafter, examples related to the present invention will be illustrated in the drawings and described in detail through detailed description. However, the present invention is not limited to the embodiments disclosed below, but can be embodied in various forms, and includes all changes, equivalent technical solutions, or replacement technical solutions within the spirit and technical scope of the present invention.

[0037] In describing the structural elements of the present invention, the terms of first, second, A, B, (a), (b), etc. may be used. This term is only used to distinguish two kinds of structural elements, and the nature, sequence or order of the corresponding structural elements are not limited to this term. In addition, in this specification, when it is described as "connecting", "combining" or "linking" with other structural elements, such structural elements are directly connected or connected with other structural elements, and may also be used in ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com