Built-in single-face thin-film throttling static-pressure lead screw pair

A built-in, screw pair technology, applied in the direction of hydrostatic bearings, transmissions, shafts and bearings, can solve the problems of poor sensitivity of slide valves, improve throttling performance, avoid poor throttling performance, reduce The effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further elaborate the technical means and effects that the present invention adopts for reaching the intended invention purpose, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the present invention are described in detail as follows:

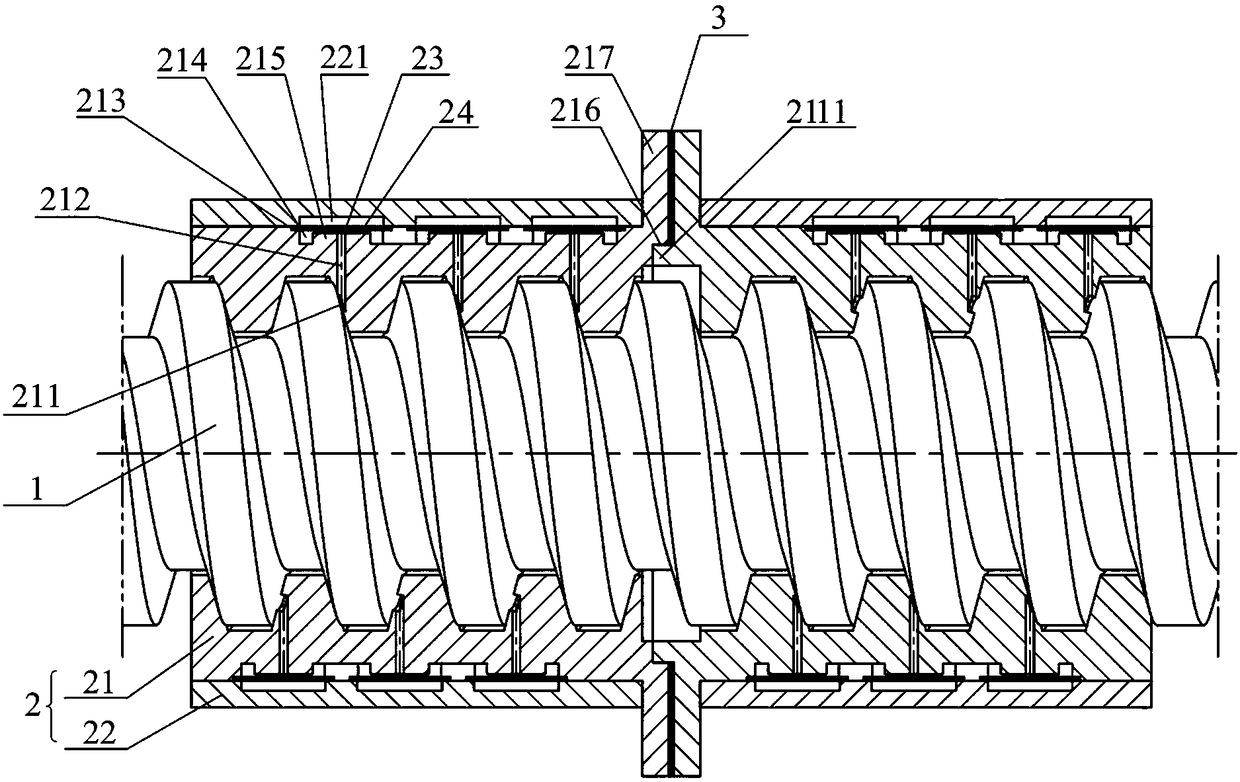

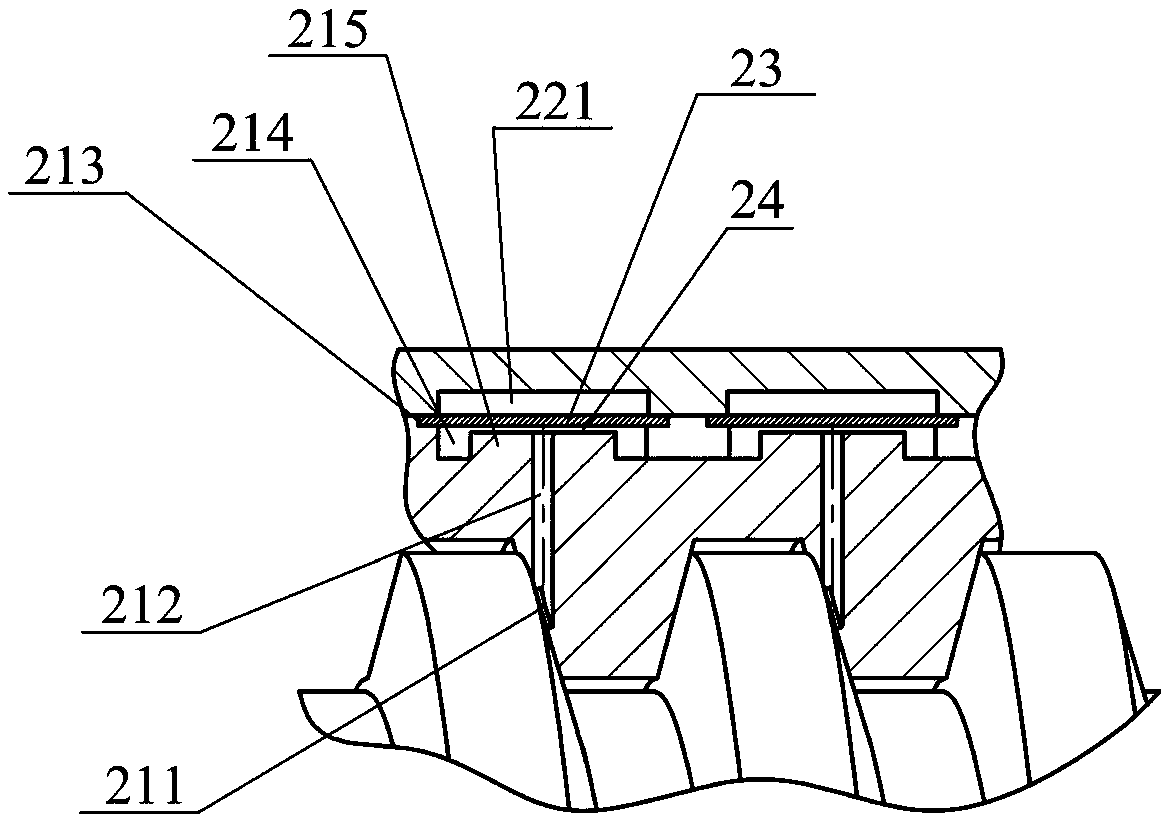

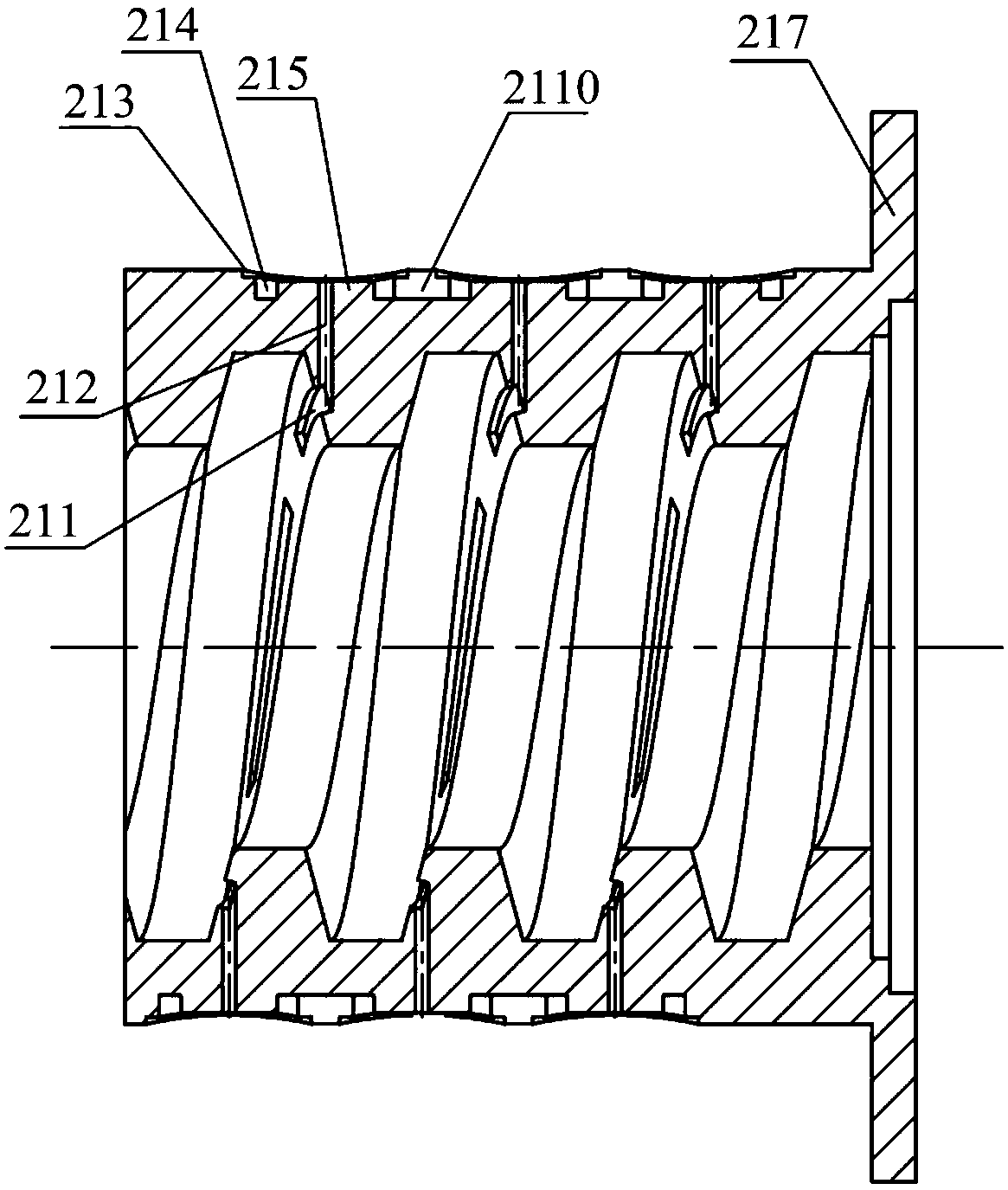

[0030] A built-in single-sided film throttling static pressure screw pair, such as Figure 1 to Figure 6 As shown, it includes a lead screw 1 and a nut 2 that cooperates with the lead screw 1 . The nut 2 includes an inner sleeve 21 and an outer sleeve 22 that cooperate with each other and a plurality of films 23 . In the following, the inner sleeve 21 and the outer sleeve 22 will be described separately first, and then the structural relationship between the two will be described in conjunction with specific implementation conditions.

[0031] refer to Figure 1 to Figure 4 , the internal helical surface of the inner sleeve 21 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com