Extended Equivalent Method Extensometer Deformation Monitoring Method

A technology of deformation monitoring and convergence meter, applied in the direction of mechanical solid deformation measurement, etc., can solve the problems of high cost, safety threat, high risk, etc., and achieve the effect of avoiding the interference of construction factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0268] Implementation mode 1: Large-scale construction tunnel geological surrounding rock convergence deformation monitoring

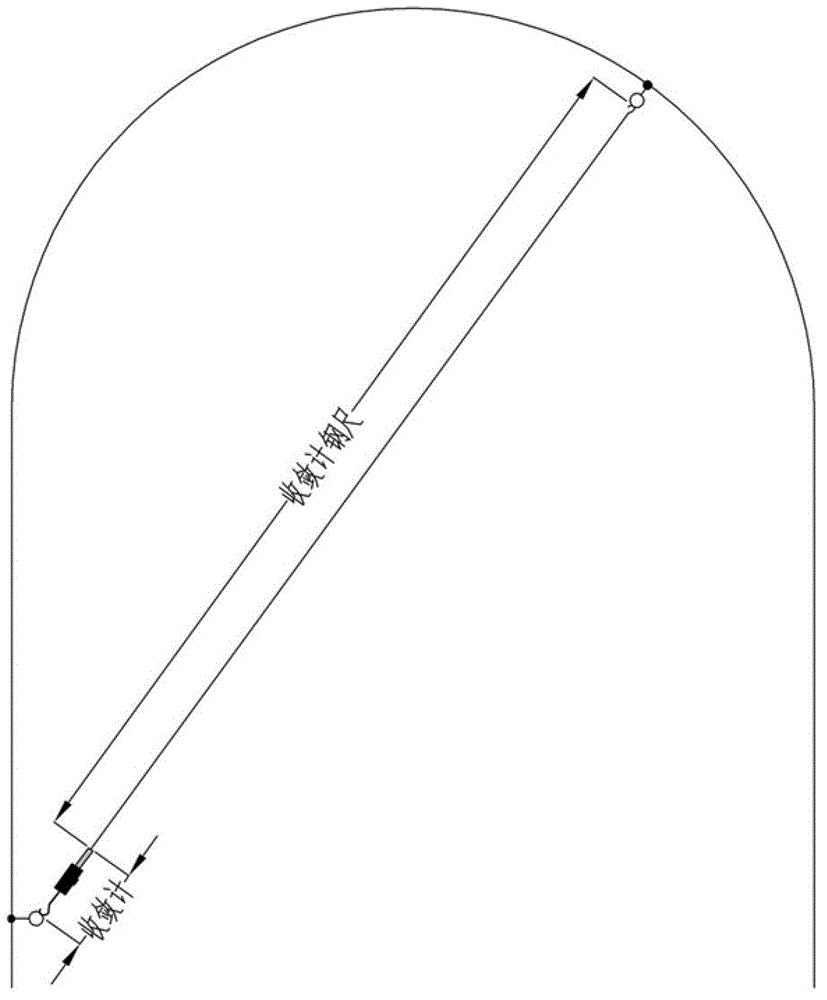

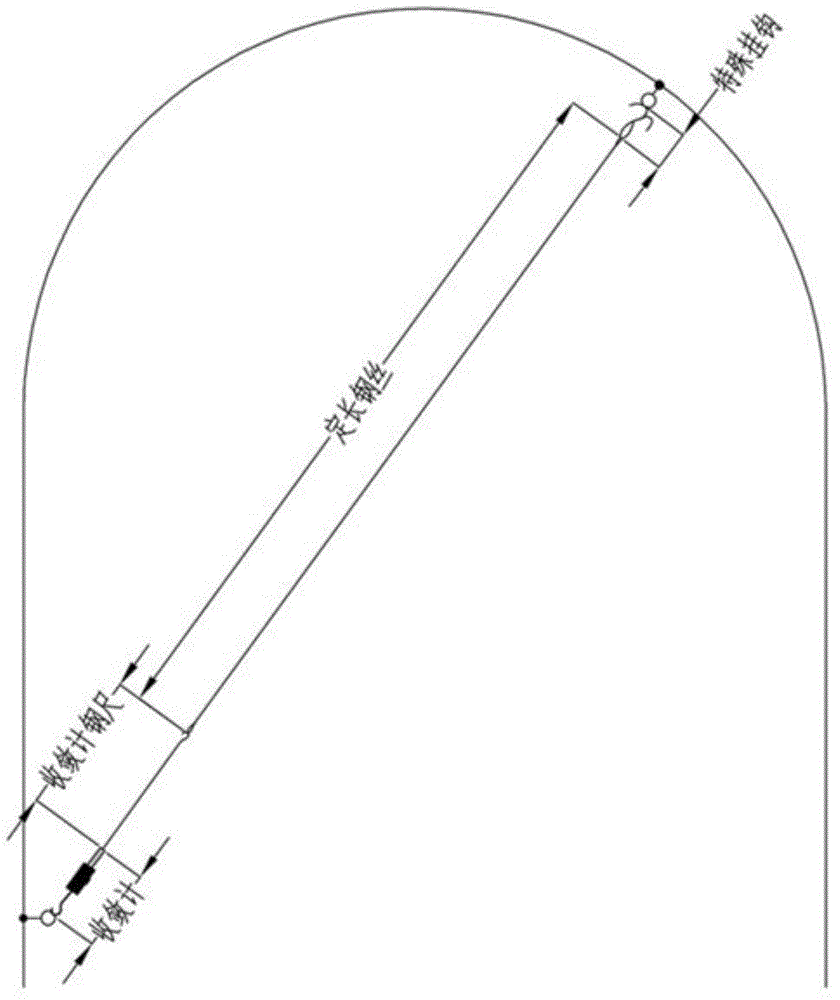

[0269] The present invention can use two methods to measure the distance of the feature edge to the monitoring of the convergence deformation of the geological surrounding rock of the large-scale construction tunnel: one is to use the convergence meter steel ruler completely, such as figure 1 shown; the second is to use only a small part of the extensometer steel ruler, and the other parts use fixed-length steel wires and special hooks, such as figure 2 shown. Because the present invention only cares about the difference Δl between the subsequent monitoring of the characteristic edge and the initial value during the monitoring process, it is sufficient to use a small section of extensometer steel ruler in order to obtain accurate observation readings from the extensometer.

[0270] one. Direct use of extensometer steel ruler (not recommended)

[0...

Embodiment approach 2

[0378] Implementation Mode 2: Deformation Monitoring of Tunnel Floor Uplift

[0379] AB is a vertical line segment, A is located at the top of the tunnel, and B is located at the bottom of the tunnel. Measure the length S of AB directly with an extensometer AB , and with its initial value Compare the amount of change , then use the present invention to measure the vertical displacement y of point A, then the uplift of the base plate is δ AB -y≥0, if the equal sign is established, no uplift of the bottom plate occurs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com