Method for predicting coal seam hydraulic fracturing permeability

A technology of hydraulic fracturing and prediction method, applied in permeability/surface area analysis, measurement device, suspension and porous material analysis, etc., can solve the problem that coal seam permeability cannot be quantitatively characterized, and achieve the effect of improving pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

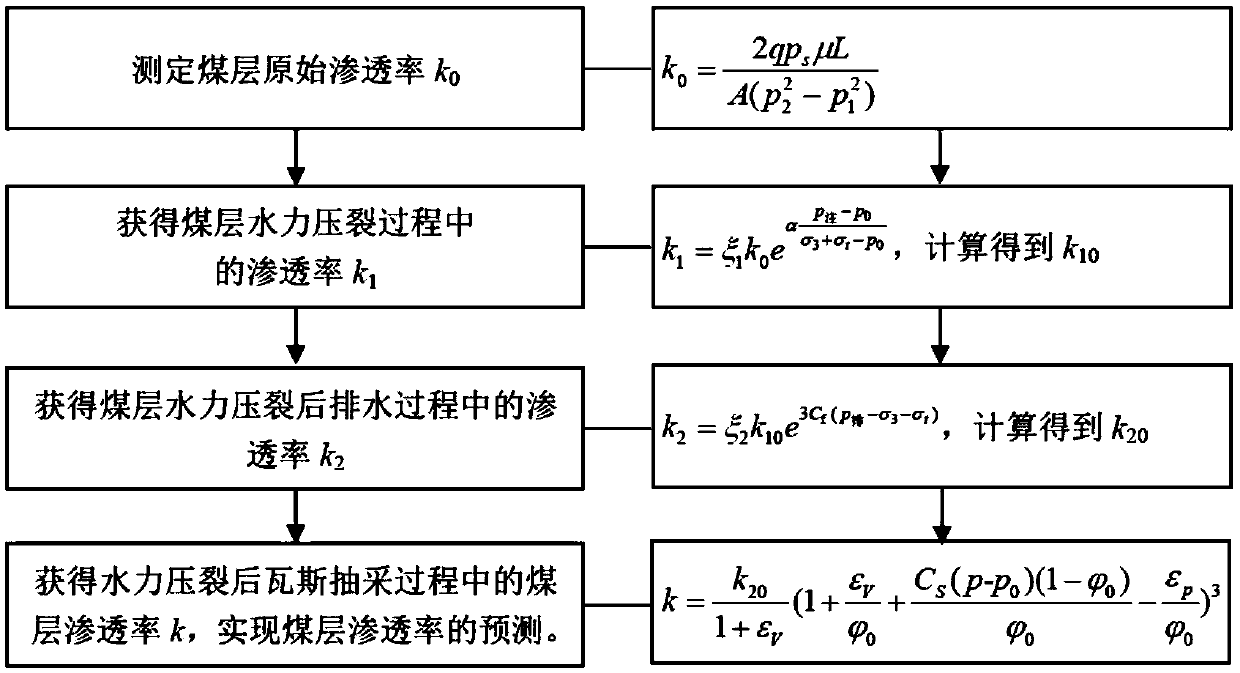

[0030] Such as figure 1 Shown, a kind of coal seam hydraulic fracturing permeability prediction method of the present invention comprises the following steps:

[0031] (1) Determination of coal seam original permeability k by permeability test 0 ;

[0032] The specific steps of the step (1) are: collecting coal samples from hydraulic fracturing coal seams and drilling coal cores with a coring machine to process them into standard test pieces, placing the test pieces between the upper pressure head and the lower pressure head of the pressure chamber according to the maximum principal stress of the coal seam hydraulic fracturing site (σ 1 ) and minimum principal stress (σ 3 ) size, the corresponding axial pressure (σ 1 ) and confining pressure (σ 3 ), read the fluid flow rate (q) through the flowmeter, and measure the original permeability k of the specimen 0 , k 0 It is obtained by the following calculation formula:

[0033]

[0034] In the formula: k 0 is the origi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com