Water-transmission dynamic scaling experiment loop and method for non-metal pipe

A non-metallic tube and experimental technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of reducing the effective diameter of the pipeline, blocking the pigging ball, and the influence of the temperature field, so as to overcome the scaling characteristics. Influence, avoid errors, the effect of uniform experimental temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail with reference to the accompanying drawings and specific implementation examples.

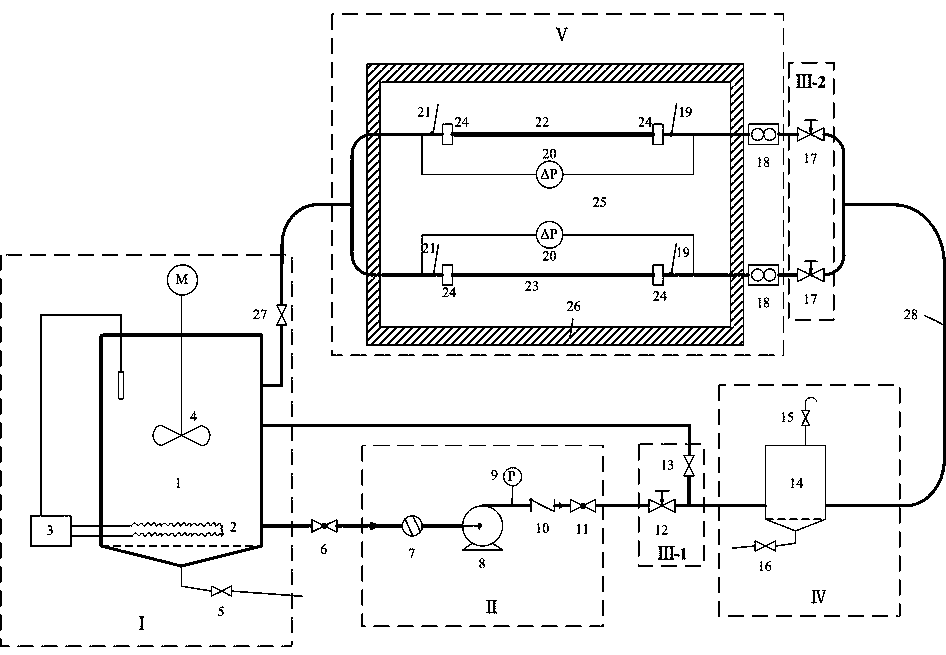

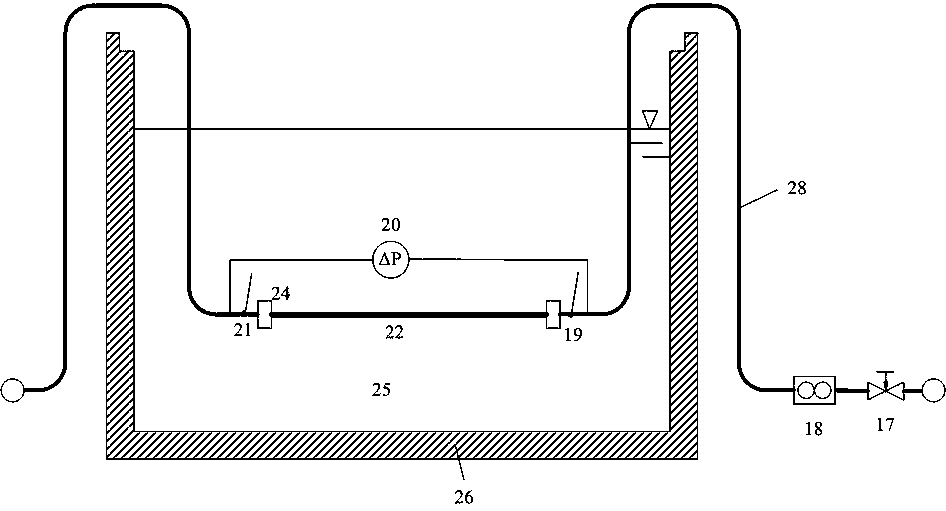

[0025] Such as figure 1 As shown, the loop device of the pipe water dynamic fouling experiment provided by the present invention includes five parts: a liquid storage system, a power system, a flow regulation system, a pressure buffer system, and a parallel test system.

[0026] The liquid storage system includes a liquid storage tank 1 , a heating system 2 , a temperature control system 3 , a stirring blade 4 driven by a motor, and a vent valve 5 . The liquid storage tank 1 is a skid-mounted vertical container. In a preferred embodiment, the upper part of the liquid storage tank 1 is cylindrical, and the lower part is conical. An outlet is provided on the side of the cylinder near the lower end, and two inlets are arranged near the upper end. The outlet is connected to the power system; one of the inlets is parallel to the normal line of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com