Microwave Electric Coupling Structure and Its Realization Method

A technology of electrical coupling and microwave, applied in the field of electronics, can solve the problem that the magnetic coupling structure is not easy to transmit zero points, etc., and achieve the effect of excellent out-of-band suppression characteristics, easy implementation, and high electrical coupling coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

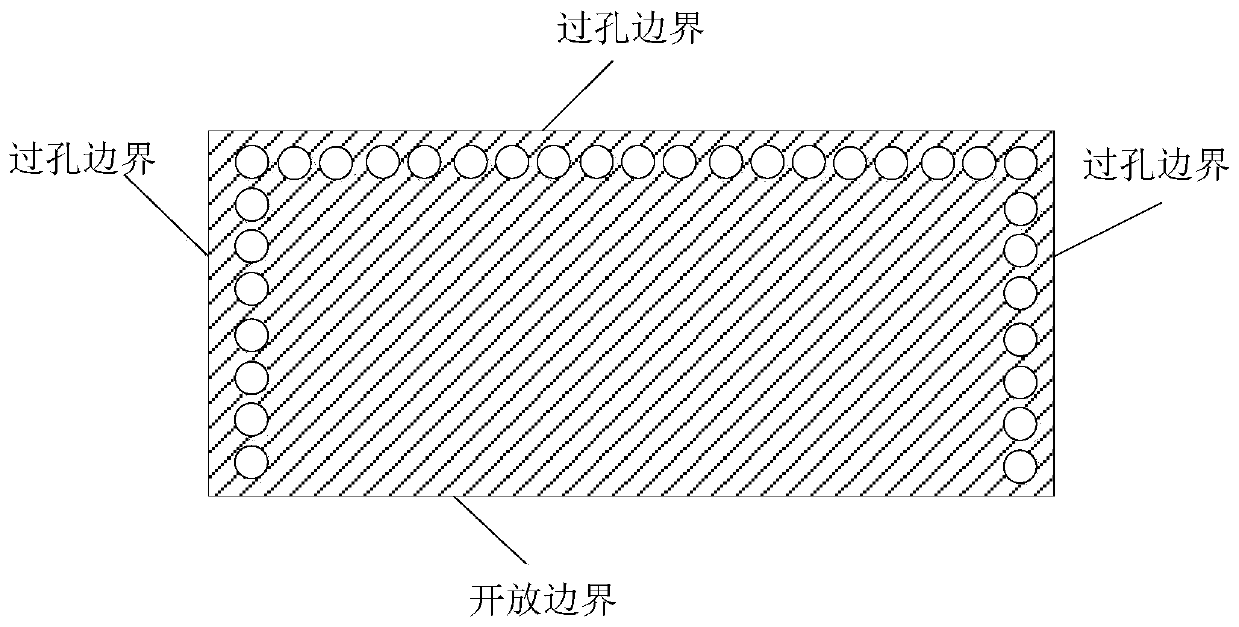

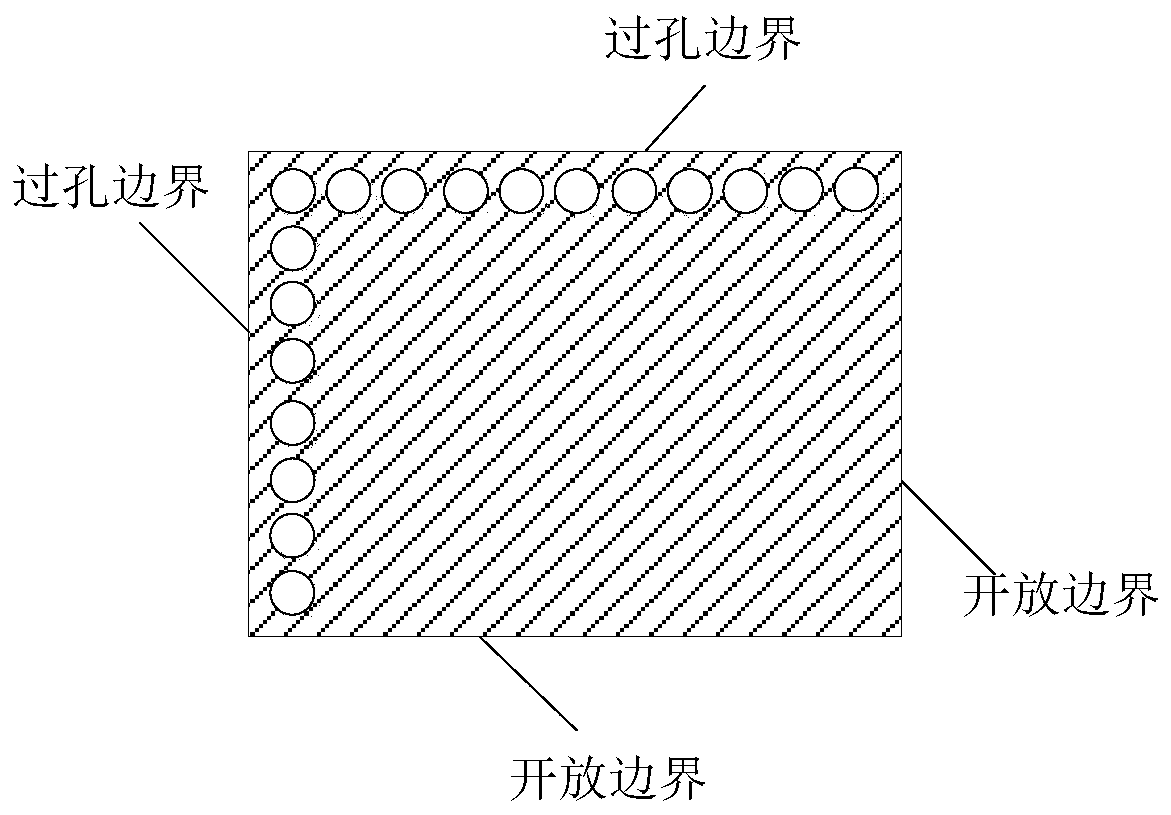

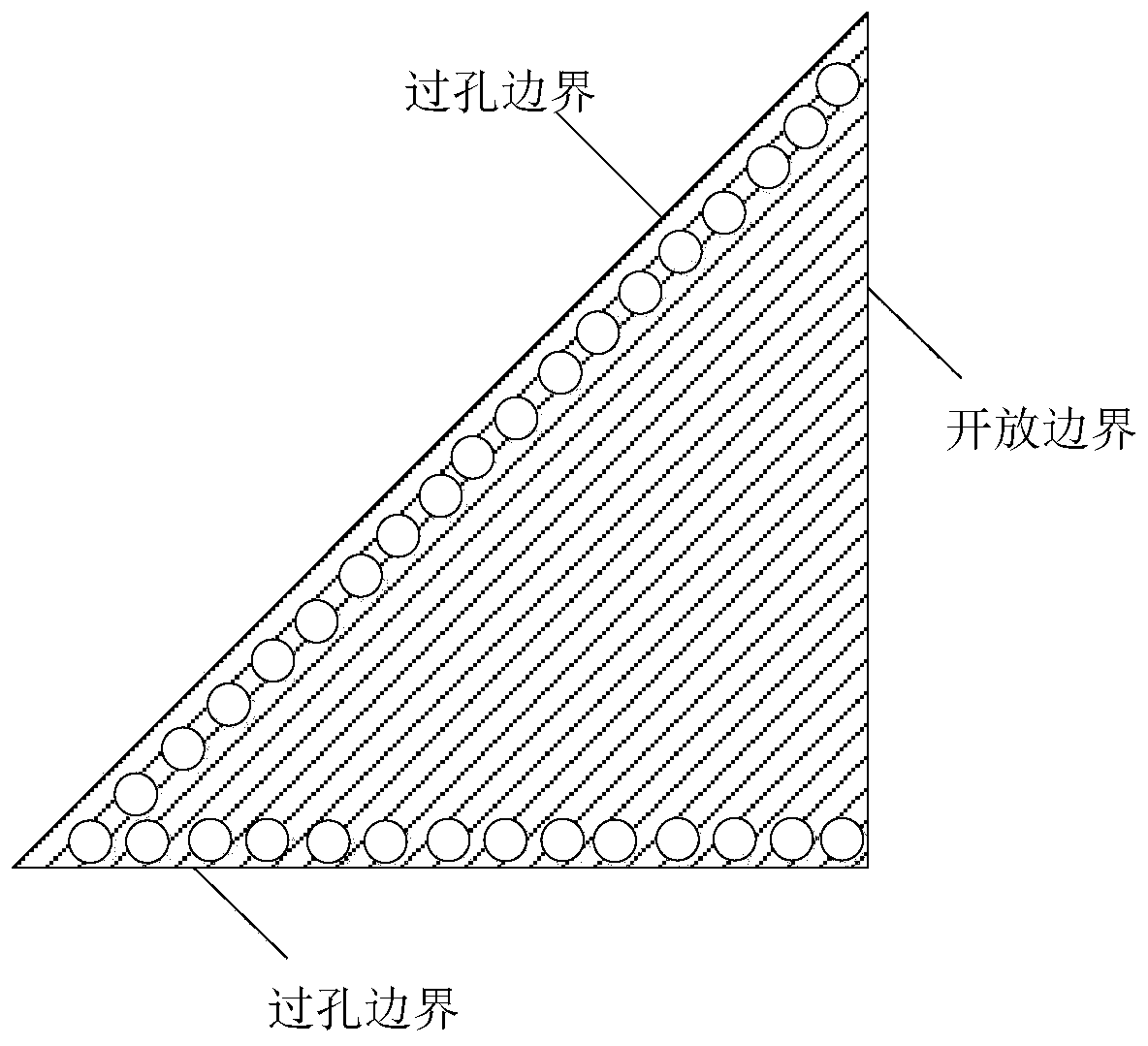

[0026] The microwave electrical coupling structure of the embodiment of the present invention can be applied to microwave devices such as filters, antennas, oscillators, couplers, etc. using substrate integrated waveguides, that is, can be applied to microwave circuits using these microwave devices. The substrate-integrated waveguide uses adjacent metallized through holes on the dielectric substrate to form an electric wall, and forms a structure similar to a common waveguide together with the upper and lower metal surfaces. The substrate-integrated waveguide resonator includes a metal top layer, a dielectric layer and a bottom layer. The metal vias of the resonator pass through the metal top layer, the dielectric layer and the bottom layer, and the bottom layer is all metallized to form an electrical ground. The metal used for metal vias, metal top layer an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com