Automatic clamping safety socket

A safety socket and automatic clamping technology, which is applied to contact parts, electrical components, coupling devices, etc., can solve the problems of reduced contact performance and reduced elasticity of copper sheets, so as to reduce fatigue strength, increase service life, and reduce bending The effect of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

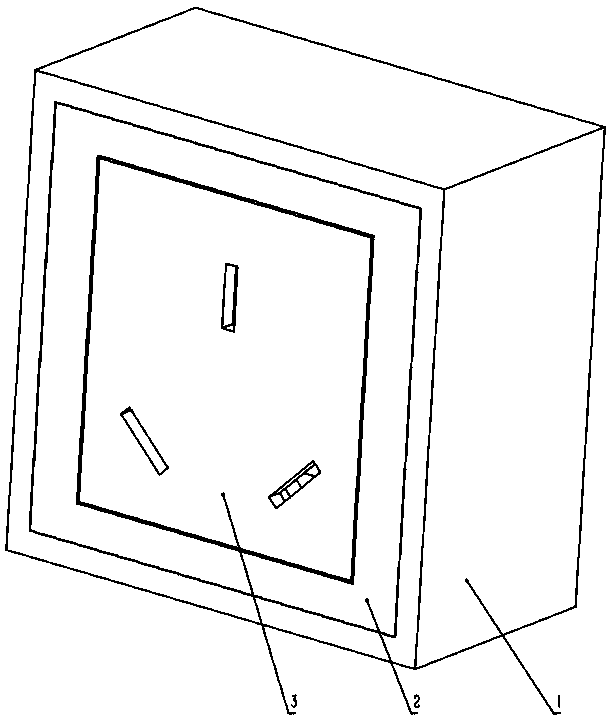

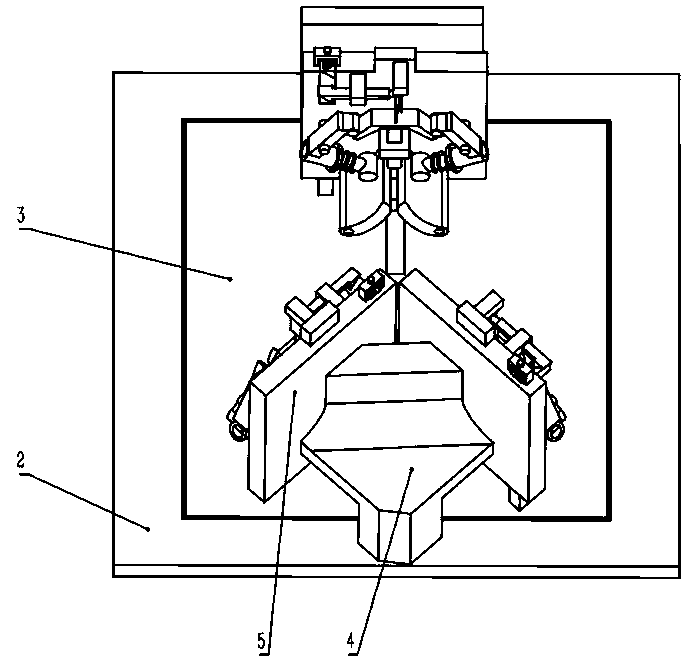

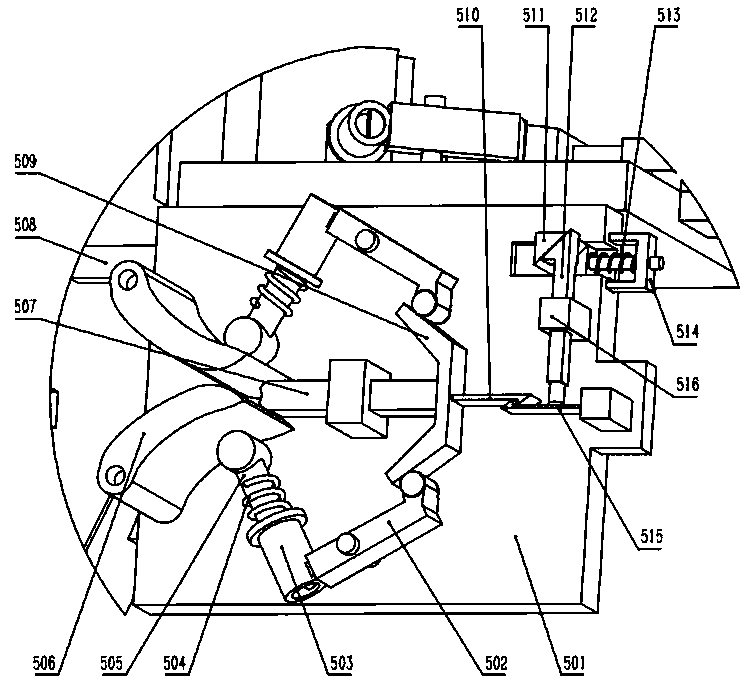

[0014] Such as figure 1 , figure 2 As shown, a self-clamping type safety socket includes a shell 1, a return frame 2, a panel 3, a bracket 4, and a contact unit 5, and it is characterized in that: the panel 3 is arranged in a rectangular shape in the middle of the return frame 2. In the hole, the shell 1 is arranged outside the loop frame 2, the loop frame 2 and the shell 1 are connected by screws, and the panel 3 is provided with a socket; the back of the loop frame 2 is provided with a bracket 4 for installing the contact unit 5 A contact unit 5 is provided at the rear of each socket, and the contact unit 5 includes a bottom plate 501, a swing rod 502, a sleeve 503, a compression spring A504, a telescopic rod 505, a contact copper sheet 506, a push rod 507, Push rod 508, ladder frame 509, hook A510, inclined plane top block A511, inclined plane top block B512, compression spring B513, fixed frame 514, hook B515, fixed block 516, described base plate 501 is fixedly installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com