Production method of fine circuit of single-sided COF flexible substrate and product obtained through production method

A flexible substrate and fine circuit technology, which is applied in the production of COF single-sided flexible substrate fine circuit and its products, can solve the problem that the minimum line width/line spacing does not reach 10 microns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The fine circuit of COF single-sided flexible substrate is made by the following steps:

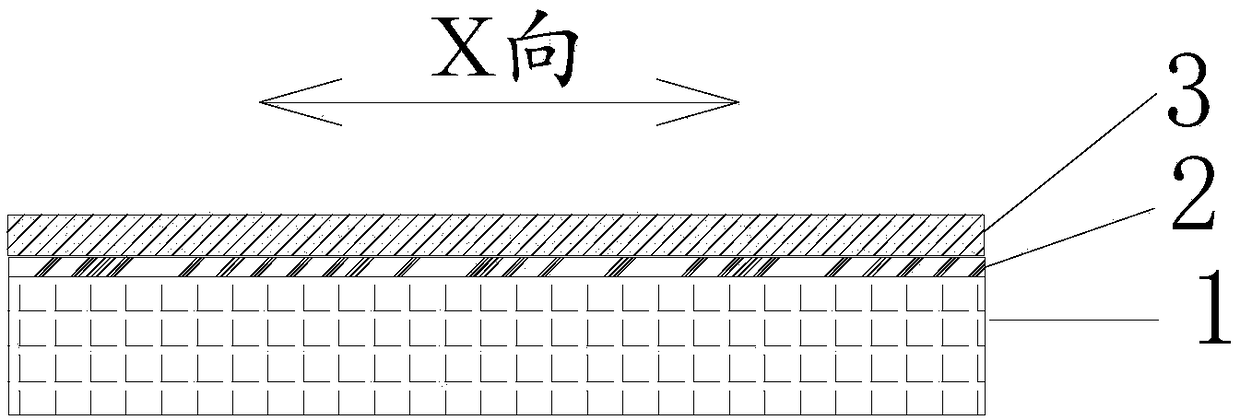

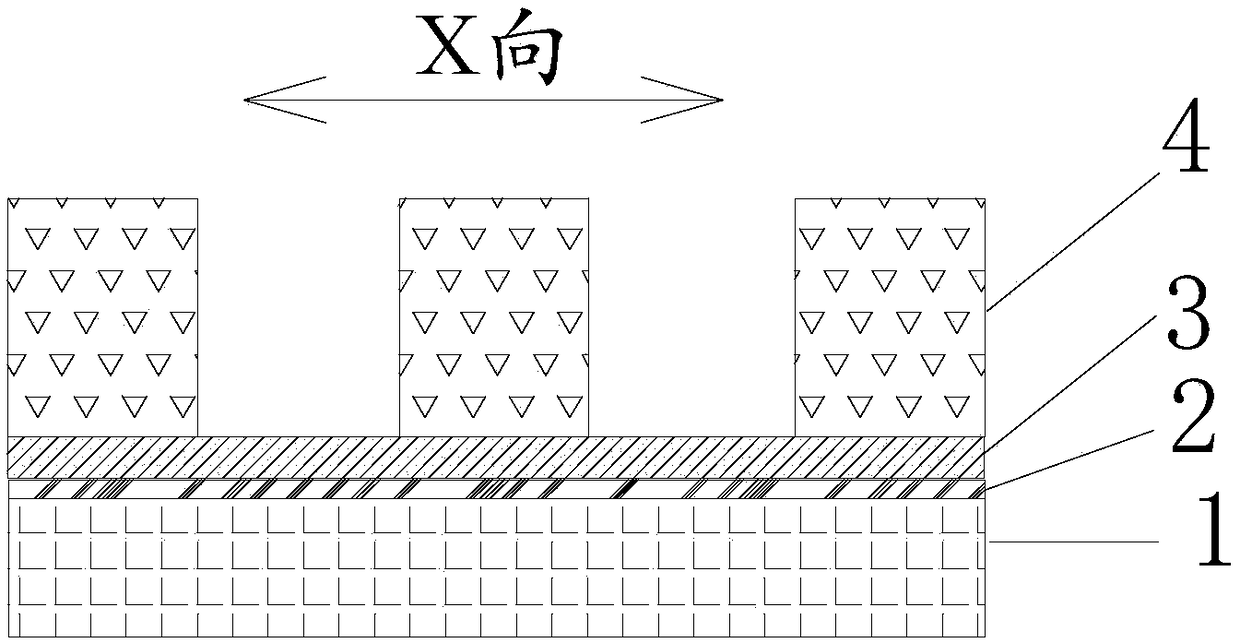

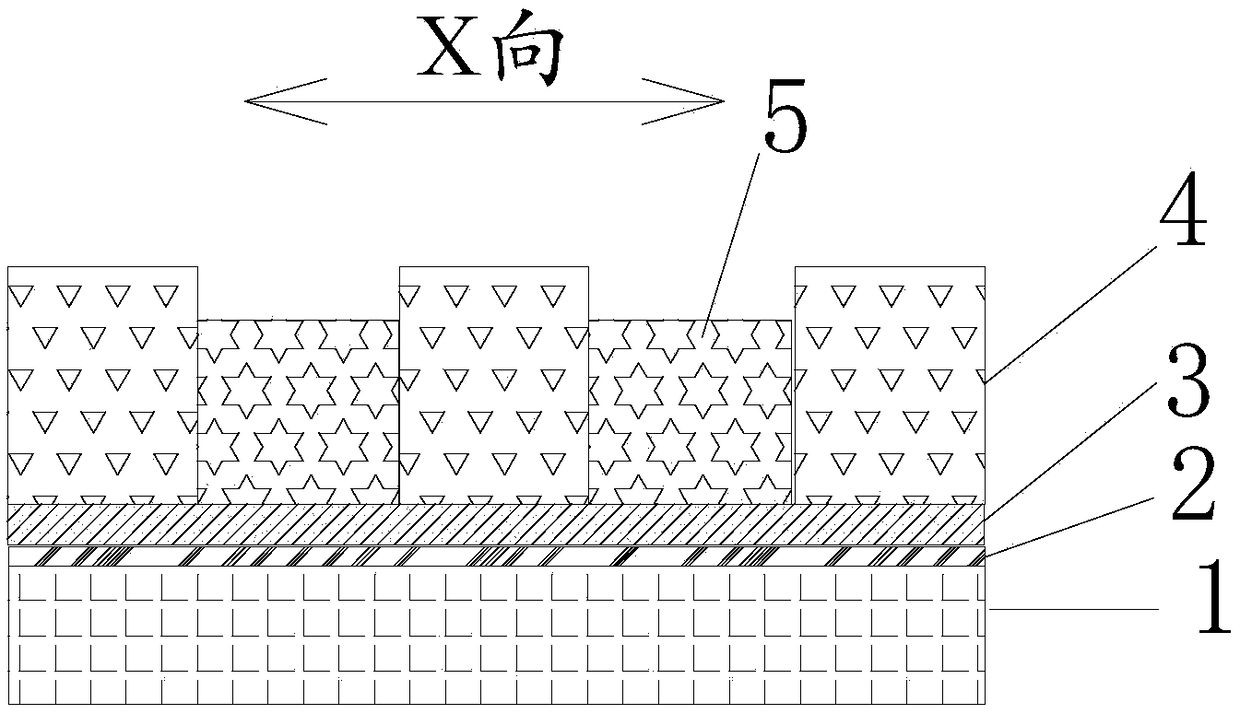

[0029] (1) Dry film lamination: a metal Ni / Cr layer 2 with a thickness of 20 nanometers is set on the upper surface of the polyimide lower layer 1, and a copper layer 3 with a thickness of 1 micron is set on the upper surface of the metal Ni / Cr layer 2 Make the substrate, and form a dry film with a thickness of 15 microns by vacuum pressing on the upper surface of the copper layer 3;

[0030] (2) UV exposure of dry film: cover the glass negative on the dry film, the glass negative includes transparent areas and black areas spaced one by one in the X direction, the size of each transparent area in the X direction is 5 microns, each black The X-direction size of the area is 9 microns. Use ultraviolet rays to irradiate and expose the dry film covered with the glass negative film and then remove the glass negative film. The part covered by the transparent area on the dry film is the ex...

Embodiment 2

[0038] The difference from Example 1 is: in step (2), the X-direction dimension of each transparent area and dry film exposed portion 4 is 4 microns, and the X-direction dimension of each black area and dry film unexposed portion is 10 microns. Micron.

Embodiment 3

[0040] The difference from Example 1 is: in step (1), the thickness of copper layer 3 is 0.5 micron; in step (2), the X-direction size of each transparent area and dry film exposure part 4 is 6 microns, each Both the black area and the unexposed portion of the dry film had an x-dimension of 8 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com